19

OPERATING INSTRUCTIONS

IMPORTANT - PLEASE READ

BEFORE USING STOVE

BURNING PROCESS

In recent years there has been an increasing con-

cern about the quality of our air. Much of the blame

for poor air quality has been placed on the burning of

wood for home heating. In order to improve the situa-

tion, we at Heat-N-Glo have developed cleaner burn-

ing wood stoves that surpass the stringent require-

ments for emissions established by our governing

agencies.

Properly operated and maintained your WS-150 or

WS-250 wood stove will obtain the peak efficiency

and lowest emissions possible, resulting in better air

quality for your community and more heat output per

pound of wood. Improper operation and maintenance

may cause any wood burning unit to release more

particulate and adversely affect the environment.

It helps to know a little about the actual process of

burning in order to understand how to operate the

stove for best performance. The first stage of burn-

ing we will call the kindling stage. In this stage, the

wood is heated to a temperature high enough to

evaporate the moisture which is present in all wood.

The wood will reach the boiling point of water (212°F)

and will not get any hotter until the water is evapo-

rated. This process takes heat from the coals and

tends to cool the stove. Fire requires three things to

burn: fuel, air and heat. So, if heat is robbed from the

stove during the drying stage, the new load of wood

has reduced the chances for a good clean burn. For

this reason, it is always best to burn dry, seasoned

firewood. When the wood isnt dry, you must open

the air controls and burn the stove at a high burn set-

ting for a longer time to start it burning. The control on

the right side of the stove is called the

primary con-

trol; it is used mainly during the kindling stage of burn-

ing, or when burning the stove at a high burn setting.

It should be closed (pulled outward) for lower burns.

The next stage of burning, the secondary stage, is

the period when the wood gives off flammable gases

which burn above the fuel with bright flames. During

this stage of burning it is very important that the flames

be maintained and not allowed to go out. This will in-

sure the cleanest possible fire. If you are adjusting

your stove for a low burn rate, you should close down

the air to the point where you can still maintain some

flame. If the flames tend to go out, the stove is set too

low for your burning conditions. The air control in the

center of the stove, beneath the ash catcher, is the

one used to adjust the stove for lower burn rates. This

is called the

secondary control. Pulling either control

towards you closes it, pushing it in opens it.

The final stage of burning is the charcoal stage. This

occurs when the flammable gases have been mostly

burned and only charcoal remains. This is a naturally

clean portion of the burn. The coals burn with hot blue

flames. It is very important to reload your stove while

enough lively hot coals remain in order to provide the

amount of heat needed to dry and rekindle the next

load of wood. It is best to open the air controls for a

short while before reloading. This livens up the coal

bed. Open door slowly so that ash or smoke does not

exit stove through opening. You should also break up

any large chunks and distribute the coals so that the

new wood is laid on hot coals.

Following these standards for operation and mainte-

nance is a responsible action for the choice to heat

your home with wood. In addition, you will also ex-

tend the life of your wood stove for many years of use

and enjoyment.

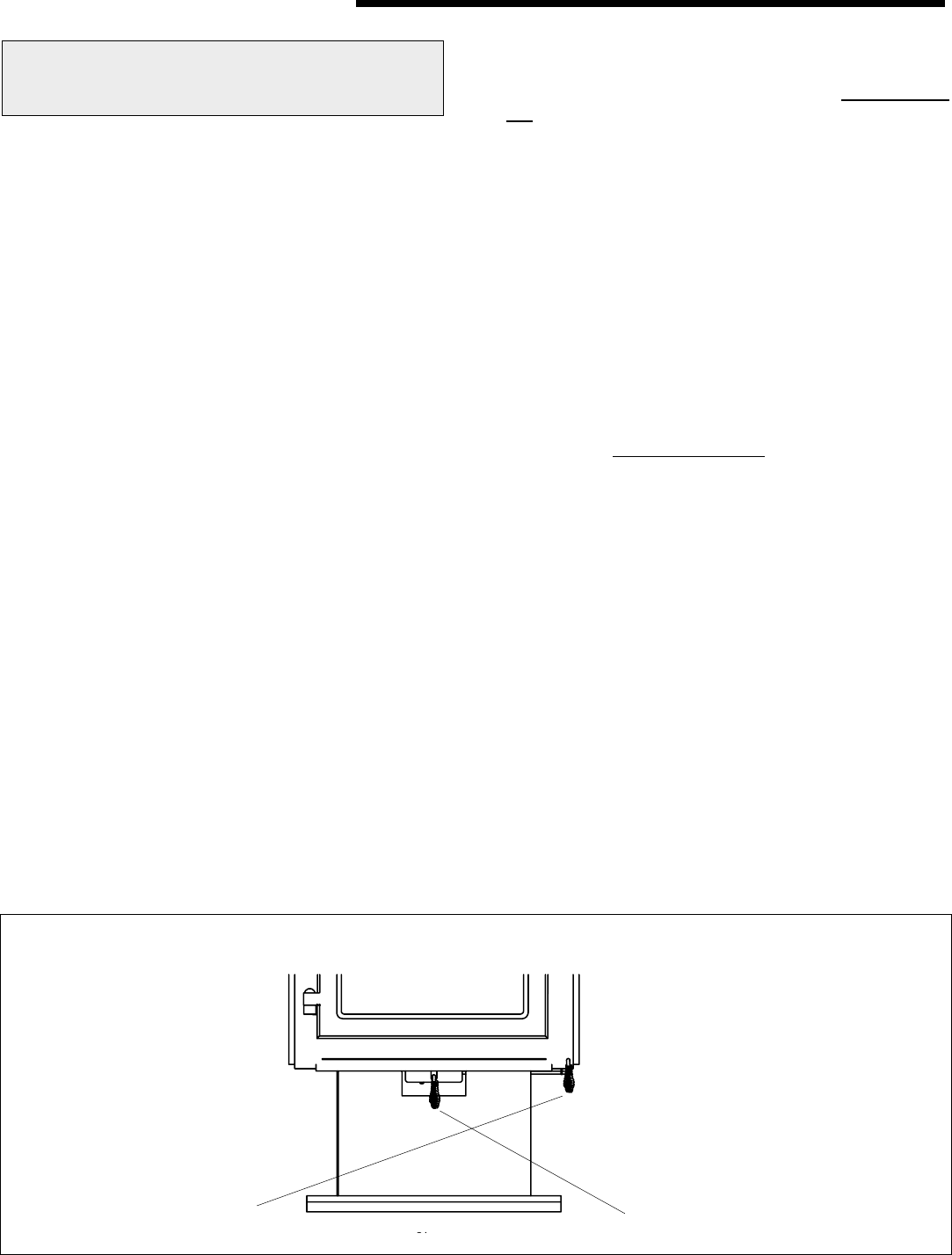

FIGURE 24

Primary

Control

Secondary

Control

SECONDARY AIR SYSTEM

The secondary air enters at the upper

front of the firebox, near the top of the

glass door. This preheated air supplies

the necessary fresh oxygen to mix with

the unburned gases, helping to create

secondary, tertiary and quaternary

combustions. This air is regulated by

the secondary control. For more sec-

ondary air push control in, for less sec-

ondary air pull control out.

PRIMARY AIR SYSTEM

The primary combustion air

enters at the rear of the fire-

box through the primary air

tubes. For more heat push

control in, for less heat pull

control out.