43

Installation, Operation & Maintenance HTV/HTD/HTH SERIES Heat Controller, Inc.

General

If operational diffi culties are encountered, perform the preliminary

checks below before referring to the troubleshooting charts.

• Verify that the unit is receiving electrical supply power.

• Make sure the fuses in the fused disconnect switches

are intact.

After completing the preliminary checks described above,

inspect for other obvious problems such as leaking connections,

broken or disconnected wires, etc. If everything appears to

be in order, but the unit still fails to operate properly, refer to

the “CXM Troubleshooting Process Flowchart” or “Functional

Troubleshooting Chart.”

CXM Board

CXM board troubleshooting in general is best summarized as

simply verifying inputs and outputs. After inputs and outputs

have been verifi ed, board operation is confi rmed and the problem

must be elsewhere. Below are some general guidelines for

troubleshooting the CXM control.

Field Inputs

All inputs are 24VAC from the thermostat and can be verifi ed

using a volt meter between C and Y, G, O, W. 24VAC will be

present at the terminal (for example, between “Y” and “C”) if the

thermostat is sending an input to the CXM board.

Sensor Inputs

All sensor inputs are ‘paired wires’ connecting each component to

the board. Therefore, continuity on pressure switches, for example

can be checked at the board connector.

The thermistor resistance should be measured with the

connector removed so that only the impedance of the thermistor

is measured. If desired, this reading can be compared to the

thermistor resistance chart shown in the CXM AOM manual. An

ice bath can be used to check calibration of the thermistor.

Outputs

The compressor relay is 24VAC and can be verifi ed using a

voltmeter. The fan signal is passed through the board to the

external fan relay (units with PSC motors only). The alarm relay

can either be 24VAC as shipped or dry contacts for use with

DDC controls by clipping the JW1 jumper. Electric heat outputs

are 24VDC “ground sinking” and require a volt meter set for DC

to verify operation. The terminal marked “24VDC” is the 24VDC

supply to the electric heat board; terminal “EH1” is stage 1 electric

heat; terminal “EH2” is stage 2 electric heat. When electric heat

is energized (thermostat is sending a “W” input to the CXM

controller), there will be 24VDC between terminal “24VDC” and

“EH1” (stage 1 electric heat) and/or “EH2” (stage 2 electric heat).

A reading of 0VDC between “24VDC” and “EH1” or “EH2” will

indicate that the CXM board is NOT sending an output signal to

the electric heat board.

Test Mode

Test mode can be entered for 20 minutes by shorting the test

pins. The CXM board will automatically exit test mode after 20

minutes.

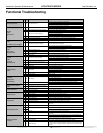

CXM Troubleshooting Process Flowchart/Functional

Troubleshooting Chart

The “CXM Functional Troubleshooting Process Flowchart”

is a quick overview of how to start diagnosing a suspected

problem, using the fault recognition features of the CXM board.

The “Functional Troubleshooting Chart” on the following page

is a more comprehensive method for identifying a number of

malfunctions that may occur, and is not limited to just the CXM

controls. Within the chart are fi ve columns:

• The “Fault” column describes the symptoms.

• Columns 2 and 3 identify in which mode the fault is likey to

occur, heating or cooling.

• The “Possible Cause column” identifi es the most likely sources

of the problem.

• The “Solution” column describes what should be done to

correct the problem.

WARNING! HAZARDOUS VOLTAGE! DISCONNECT

ALL ELECTRIC POWER INCLUDING REMOTE

DISCONNECTS BEFORE SERVICING.

Failure to disconnect power before servicing can cause

severe personal injury or death.

Troubleshooting

WARNING!