10

6. Braze the individual connections with dry nitrogen

flowing through the joints. NOTE: This will prevent

internal oxidation and scaling from occurring.

7. Wrap the refrigerant lines with pressure sensitive

neoprene or other suitable material especially where

the lines enter the opening in the sheet metal.

8. Evacuate the system of moisture and non-condensables

to prevent low efficiency operation or damage to the

unit. The suggested range of evacuation is 350 - 500

microns.

9. Charge the system with refrigerant. Refer to the

outdoor unit installation manual for additional charging

instructions.

10. Check the system for leaks, including the lineset and

the brazed joints.

11. Replace all grommets and properly dispose of all

removed parts.

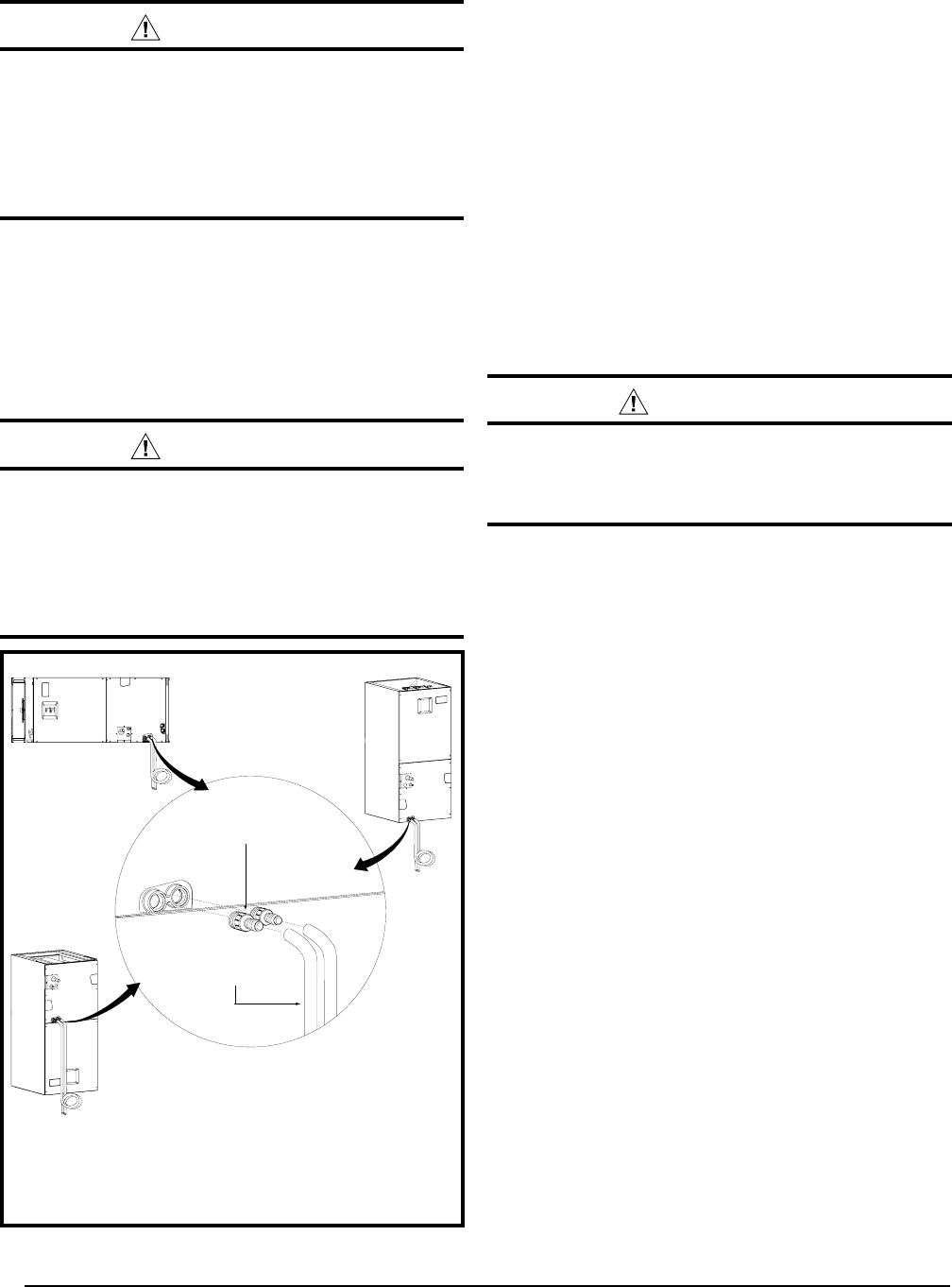

Condensate Drainage

CAUTION:

The air handler must be level to ensure proper

condensate drainage. An unlevel installation

may result in structural damage, premature

equipment failure, or possible personal injury.

• Methodsfordisposingofcondensatevaryaccording

to local codes. Refer to local codes or authority having

jurisidiction for restrictions and proper condensate

disposal requirements.

• The drain pan that is supplied with this air handler

contains a primary and secondary drain fitting. The

condensate is drained from the unit through two 3/4”

female pipe fittings located on the front side of the unit

as shown in Figure 9.

• Thedrainpanmustbedrainedwitheldsuppliedtubing

or pvc pipe and adequately trapped. Both drain tubes

must have a minimum diameter of 3/4” and be trapped

separately.

IMPORTANT: Failure to install a trap may result in

condensation overflowing the drain pan, resulting in

substantial water damage to surrounding area.

• Routebothlinestoasuitabledrain,avoidingsharpbends

and pinching of the lines. The drain should maintain a

minimum horizontal slope in the direction of discharge

of not less than 1” vertical for every 10 ft of horizontal

run.

• Iftheairhandlerislocatedinorabovealivingspace

where damage may result from condensate overflow,

an auxiliary drain pan shall be installed under the unit.

A separate drain line should extend from the pan to a

conspicuous point and serve as an alarm indicating

that the primary drain is restricted. As an alternative to

a separate drain line, an approved water level indicator

or float switch device may be used to shut down the

unit in the event water is detected in the auxiliary pan.

1. Remove grommets from line set holes.

CAUTION:

It is recommended that a wet rag be wrapped

around the suction line in front of the close

off plate or the sensing bulb (if TXV is

installed) before applying heat. Failure to keep

components cool during brazing may result

in structural damage, premature equipment

failure, or possible personal injury.

2. Unbraze and remove the cap on the suction line.

3. Route and cut both lineset tubes to proper length in

accordance with the outdoor unit specifications. Verify

the ends are round, clean, and free of any burrs.

4. Position grommet on line set with sufficient distance away

from brazing area. Brazing processes can permanently

damage grommets.

5. Connect the suction and liquid lineset tubes.

CAUTION:

It is recommended that a wet rag be wrapped

around the suction line in front of the close

off plate or the sensing bulb (if TXV is

installed) before applying heat. Failure to keep

components cool during brazing may result

in structural damage, premature equipment

failure, or possible personal injury.

3/4” Adapter w/

3/4” dia. hose barb

3/4” minimum dia.

PVC or flexible tubing

HORIZONTAL

UPFLOW

DOWNFLOW

NOTES:

1. The drain lines must maintain a downward slope to ensure proper

condensate drainage.

2. Each condensate drain must be trapped separately using a J-Trap or

field supplied loop.

Figure 9. Condensate Drainage Example