Heat & Glo • PIER-HVB-IPI, ST-HVB-IPI • 2006-901 Rev. C • 12/07

26

4. Install Firestops

For Horizontal Runs - Firestops are REQUIRED on both

sides of a combustible wall through which the vent passes.

NOTE: Model DVP-TRAP does not need an exterior

firestop on an exterior combustible wall. The firestop is

built into the cap.

To install firestops for horizontal runs that pass through either

interior or exterior walls:

• Cut a 10” x 12” (254mm X 305mm) hole through the wall.

NOTE: The center of the hole is one (1) inch (25.4mm)

above the center of the horizontal vent pipe.

• Position the firestops on both sides of the hole previ-

ously cut and secure the firestops with nails or screws.

• The heat shields of the firestops MUST BE placed to-

wards the top of the hole.

• Continue the vent run through the firestops.

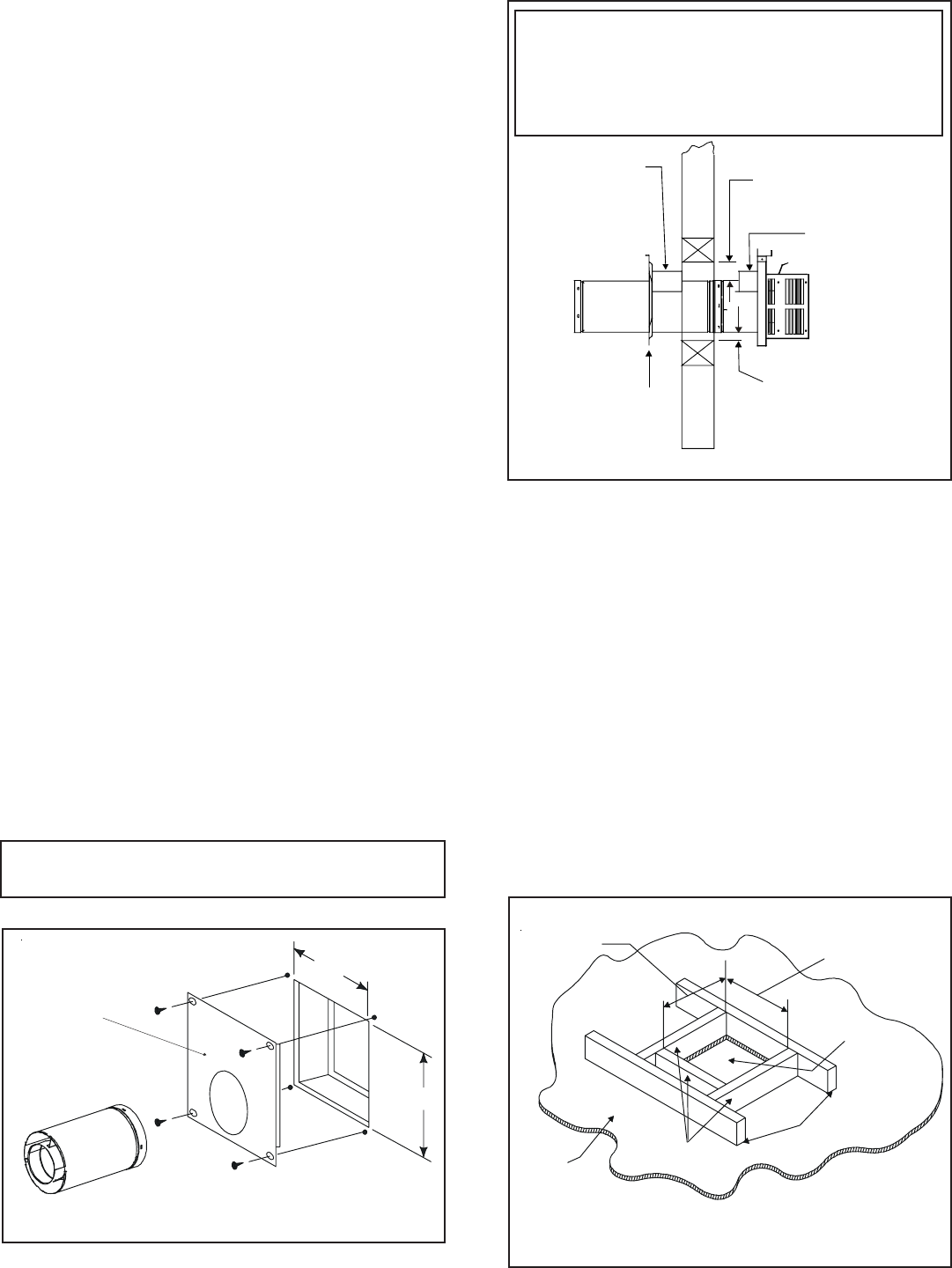

Figure 23. 10" x 12" Hole and Vent Pipe

3. Install Support Brackets

Refer to Cinch Pipe and Termination Cap installation in-

structions.

2. Continue Adding Vent Components

Refer to Cinch Pipe and Termination Cap installation in-

structions.

• Continue adding vent components, locking each succeed-

ing component into place.

• Ensure that each succeeding vent component is secure-

ly fitted and locked into the preceding component in the

vent system. Securing pipe sections with a maximum of

two screws is recommended.

• 90° elbows may be installed and rotated to any point

around the preceding component’s vertical axis. If an el-

bow does not end up in a locked position with the pre-

ceding component, attach with a minimum of two (2)

sheet metal screws.

NOTE: There must be NO INSULATION or other

combustibles inside the framed firestop opening.

10"

12"

INTERIOR

WALL SHIELD

For Vertical Runs - One ceiling firestop is REQUIRED at

the hole in each ceiling through which the vent passes.

To install firestops for vertical runs that pass through ceilings:

• Position a plumb bob directly over the center of the verti-

cal vent component.

• Mark the ceiling to establish the centerpoint of the vent.

• Drill a hole or drive a nail through this centerpoint.

• Check the floor above for any obstructions, such as wir-

ing or plumbing runs.

• Reposition the fireplace and vent system, if necessary,

to accommodate the ceiling joists and/or obstructions.

• Cut an 10-inch X 10-inch (254mm x 254mm) hole through

the ceiling, using the centerpoint previously marked.

• Frame the hole with framing lumber the same size as the

ceiling joists.

Figure 25 Hole & New Framing Members

CEILING

NEW

FRAMING

MEMBERS

EXISTING CEILING

JOISTS

CHIMNEY

HOLE

10" (254mm)

10" (254mm)

HEAT

SHIELD

HEAT

SHIELD

1 in. CLEARANCE

BOTTOM & SIDES

WALL

WALL

SHIELD

FIRESTOP

3 in. TOP

CLEARANCE

Note: Heat shields MUST overlap by a minimum of 1-1/2

in. (38mm). The heat shield is designed to be used on a

wall 4 in. to 7-1/4 in. (102mm to 184mm) thick. If wall

thickness is less than 4 in. (102mm) the existing heat

shields must be field trimmed. If wall thickness is greater

than 7-1/4 in. (184mm) a DVP-HSM-B will be required.