9

P61A Pellet Stove

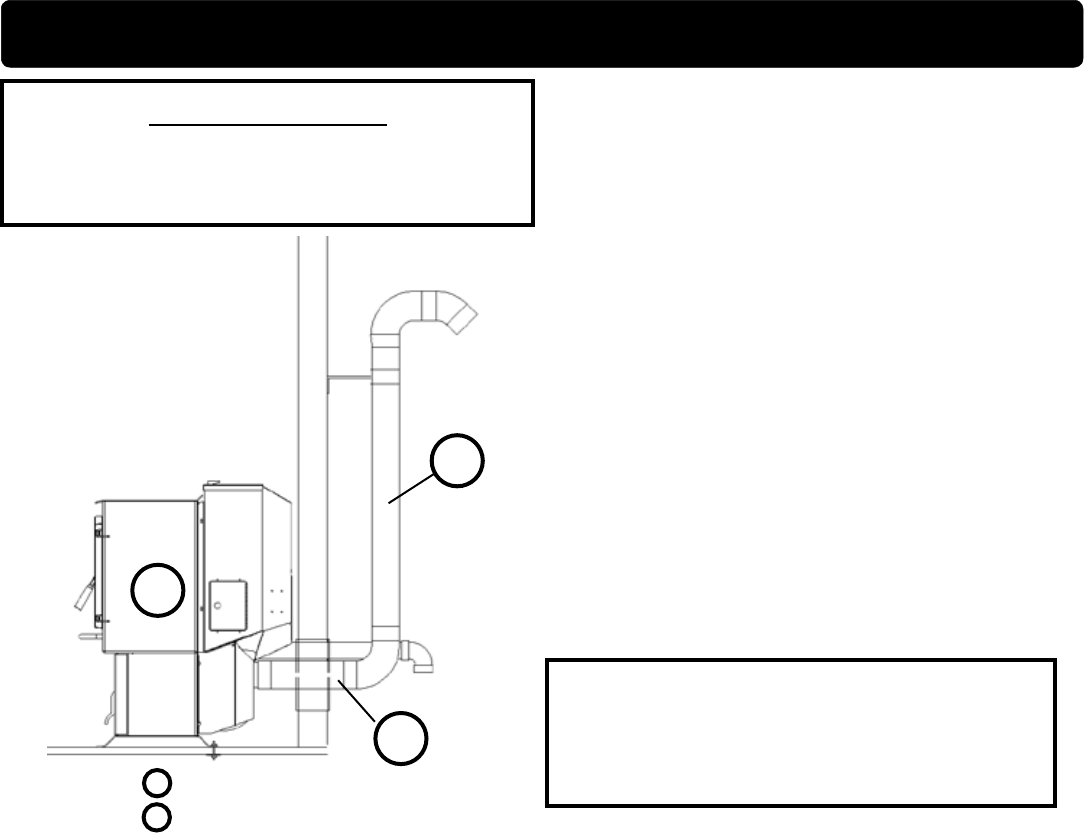

Pellet venting pipe (known as PL vent) is constructed

of two layers with air space between the layers.

This air space acts as an insulator and reduces the

outside surface temperature to allow a clearance to

combustibles of 1 to 3 inches. The sections of pipe

lock together to form an air tight seal in most cases.

However, in some cases a perfect seal is not achieved.

For this reason and the fact that the P61A operates

with a positive vent pressure

Aluminum tape

can also be used for any joint that is 1 ft. or more from

the outlet of the stove.

We cannot emphasize enough, the importance

of sealing every seam and joint in the venting system

which is inside the home. Even the smallest pin hole

can leak and when it does you will smell wood smoke

or a creosote smell in the room. If this occurs check

for leaks. Leaks are easiest to see during start-up.

Alternatively you can use a smoke pellet to leak test

the venting before lighting your rst re.

T

without exhaust

blower operation. Negative pressure in the house will

resist this natural draft if not accounted for in the pellet

appliance installation.

Heat rises in the house and leaks out at upper levels.

This air must be replaced with cold air from outdoors,

which ows into lower levels of the house. Vents and

chimneys into basements and lower levels of the house

can become the conduit for air supply, and reverse

under these conditions.

Approved Pellet Vent Pipe- Widely Known As

"PL Vent",

= Positive Static Pressure

= Negative Static Pressure

+

+

-

+

-

Fig. 7

A combustion blower is used to extract the com-

bustion gases from the rebox. This causes a negative

pressure in the rebox and a positive pressure in the

venting system as shown in Fig. 7. The longer the

vent pipe and more elbows used in the system, the

greater the ow resistance. Because of these facts we

recommend using as few elbows as possible and 15

feet or less of vent pipe. The maximum horizontal run

should not exceed 48". If more than 15 feet of pipe

is needed, the interior diameter should be increased

from 3" to 4" because a larger pipe causes less ow

resistance.

The use of a starting

collar is not always necessary. The rst piece of pipe

must be secured, with at least 2 fasteners, to the ue

collar of the stove. The 2 screws provided are self-drill-

ing, however, drilling a 3/32" pilot hole for each screw

is recommended due to the material thickness.