12

P61A Pellet Stove

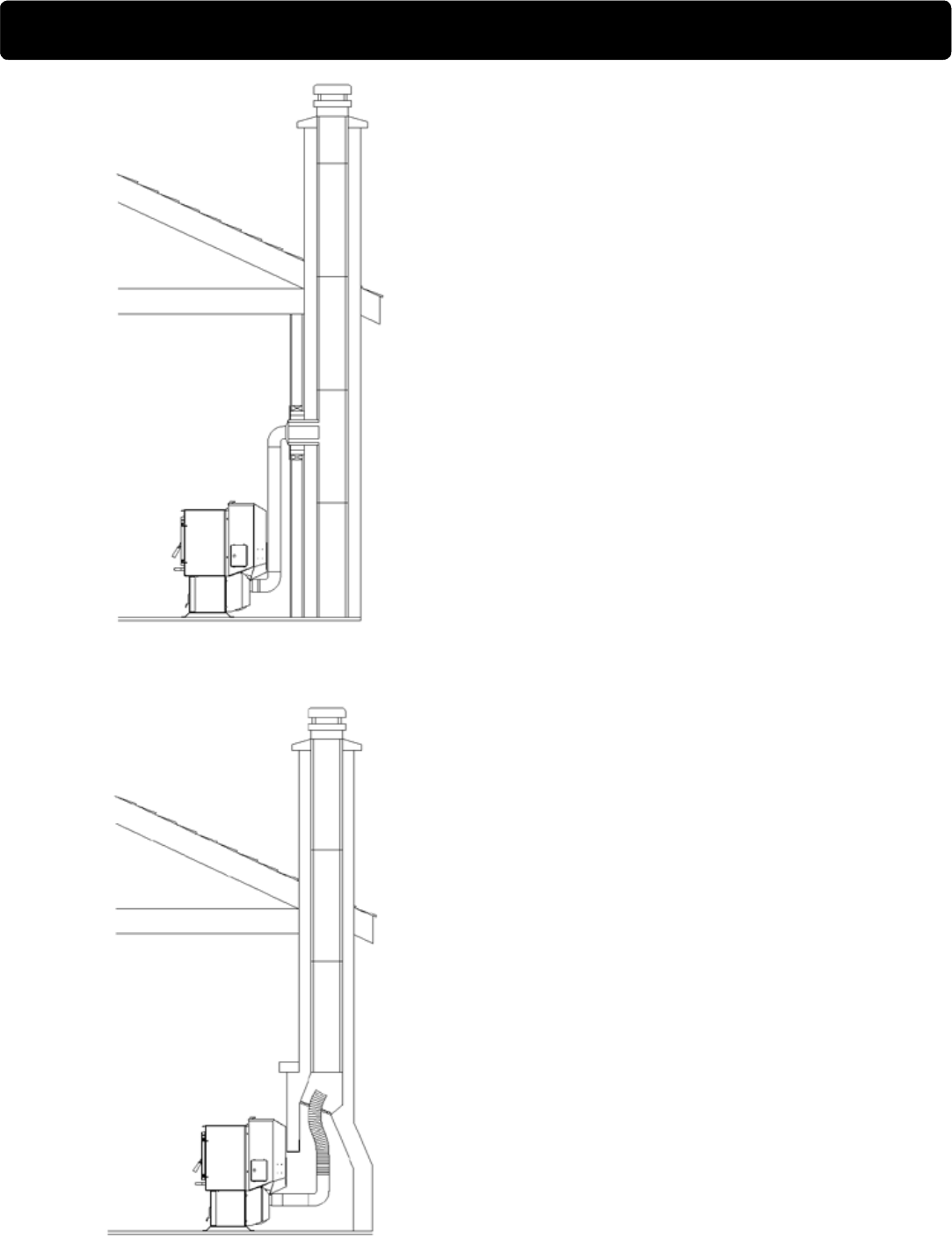

This method provides excellent venting for

normal operation. This method also provides

natural draft in the event of a power failure. If the

chimney condition is questionable* you may want

to install a liner as in method #7.

In some places in the US and Canada it is

required that the vent pipe extend all the way to the

top of the chimney.

*The chimney should be inspected and cleaned

before installing your stove. If you discover that the

chimney does not have a clay tile liner or has cracks

or aking of the tile liner you will need to install a

stainless steel liner within the chimney. In most cases

the inside diameter of this liner should be 4". Either

exible or rigid liner may be used for this purpose.

Refer to Method 6 & 7.

Be sure to design the venting so that it can be easily

cleaned.

This method provides excellent venting for

normal operation. This method also provides natural

draft in the event of a power failure. If the chimney

condition is questionable* you may want to install a

liner as in method #6.

In some places in the US and Canada it is

required that the vent pipe extend all the way to the

top of the chimney.

*The chimney must be inspected and cleaned

before installing your stove. If you discover that the

chimney does not have a clay tile liner or has cracks

or aking of the tile liner you will need to install a

stainless steel liner within the chimney, as shown

in Method 6 & 7.

The chimney must be sealed at the damper us-

ing a steel plate. Kaowool, mineral wool or other non-

combustible insulation is recommended above the

plate to reduce the possibility of condensation. The

connector pipe should extend through the smoke

chamber to the base or into the rst ue tile.

Be sure to design the venting so that it can be

easily cleaned.

Fig. 10

Fig. 11