Do not attempt to repair your water heater. Call a qualified

Oil-Burner Technician for service. Turn “OFF” the electric

power whenever the water supply is shut off. Before calling

for service, check that:

1. The heater is properly filled.

2. The electrical supply has not been interrupted.

Professional Maintenance

Except for external appearance and area tidiness, the fol-

lowing steps should be performed only by a qualified Oil-

Burner Technician.

1. Lift out the flue baffle to clean the flue. (On rear and

combination flue heaters, the top cover, insulation and

flue top cover must be removed.)

2. Insert a flue brush down the flue passage way(s) to

remove soot and dirt. Soot or carbon that falls into the

combustion chamber will burn up within a very short

time.

3. In normal use, there should be no large accumulation of

soot in the combustion chamber. If there is, remove the

burner and carefully brush or vacuum the combustion

chamber.

Flue Pipes

Once a year, inspect the flue pipe leading from the heater to

the chimney. If corrosion is evident, or discolouration at the

joints can be seen, replace the flue pipes. This should be

done by a qualified Oil-Burner Technician. Flue pipes must

be replaced by the same size flue pipe as the flue collar

(breech connection) at the heater.

Combustion Tests

Burner adjustments:

Final burner adjustments must be made using combustion

test equipment to assure proper operation. Do not fire

heater without water or sections will overheat.

1. Refer to burner manual for start-up.

2. Allow heater to heat to design condition.

3. Using combustion test equipment, adjust burner for:

a. CO

2

between 11% and 12% and a trace of smoke

between No. 0 smoke and No. 1 smoke.

b. over-fire draft -0.01 to -0.02 in. w.c. (-0.0025 to -

0.005kPa) draft in combustion chamber (+0.25 in.

w.c. (+0.062kPa) for JWF307V).

NOTE: For JWF307V also see additional “Installation

Instructions for Through-the-wall Venting Components" that

is supplied with the JWF307V.

Routine Preventative Maintenance (by

owner/operator)

As a precaution against fire, and to maintain an adequate

flow of combustion air to the heater:

• Keep the appliance area clear and free from combustible

material, gasoline and other flammable vapors and liq-

uids.

• Keep the air ventilation openings unobstructed. If dust

and lint is seen accumulating around the openings,

remove it.

• Do not pile cartons, papers, or combustible materials on

top, or near the heater (see Figure 1).

Draining and Flushing

It is recommended that the tank be drained and flushed

every 6 months to remove sediment that may build up dur-

ing operation. The water heater should be drained if being

shut down during freezing temperatures. To drain the tank,

perform the following steps:

1. Turn off the electrical supply to the water heater.

2. Close the cold water inlet valve.

3. Open a nearby hot water faucet.

4. Connect a hose to the drain valve and terminate it to an

adequate drain.

Note: The drain hose should be rated for at least 93°C

(200°F). If the drain hose does not have this rating, open the

cold water inlet valve and a nearby hot faucet until the water

is no longer hot.

5. Open the water heater drain valve and allow all the

water to drain from the tank. Flush the tank with water

as needed to remove sediment.

6. Close the drain valve, refill the tank, and restart the

heater as directed under “Water Heater Operation”.

If the water heater is going to be shut down for an extended

period, the drain valve should be left open.

Important: Condensation may occur when refilling the tank

and should not be confused with a tank leak.

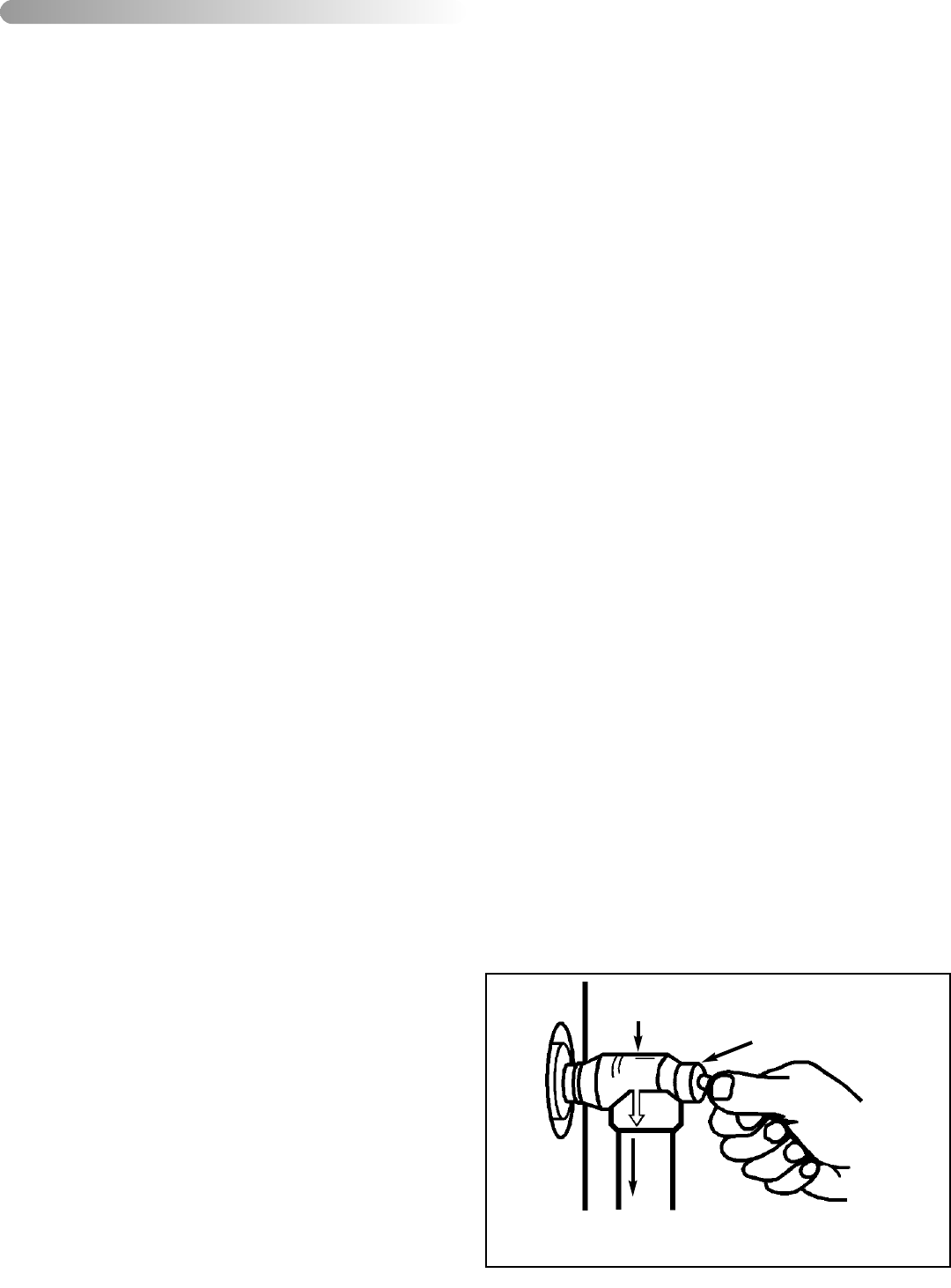

Temperature and Pressure Relief Valve

Manually operate the temperature and pressure relief valve

at least once a year to make sure it is working properly (see

Figure 12). To prevent water damage, the valve must be

properly connected to a discharge line that terminates at an

adequate drain. Standing clear of the outlet (discharged

water may be hot), slowly lift and release the lever handle on

the temperature and pressure relief valve to allow the valve

to operate freely and return to its closed position. If the valve

fails to completely reset and continues to release water,

immediately shut off the power to the heater and the cold

water inlet valve and call a qualified service technician.

V) MAINTENANCE

– 18 –

Temperature and Pressure

Relief Valve

Manual Relief Valve

Discharge line to drain

Figure 12 T&P Valve Test