Installation

6 312349G

Installation

Read instruction manual 312350 BEFORE installing this

product.

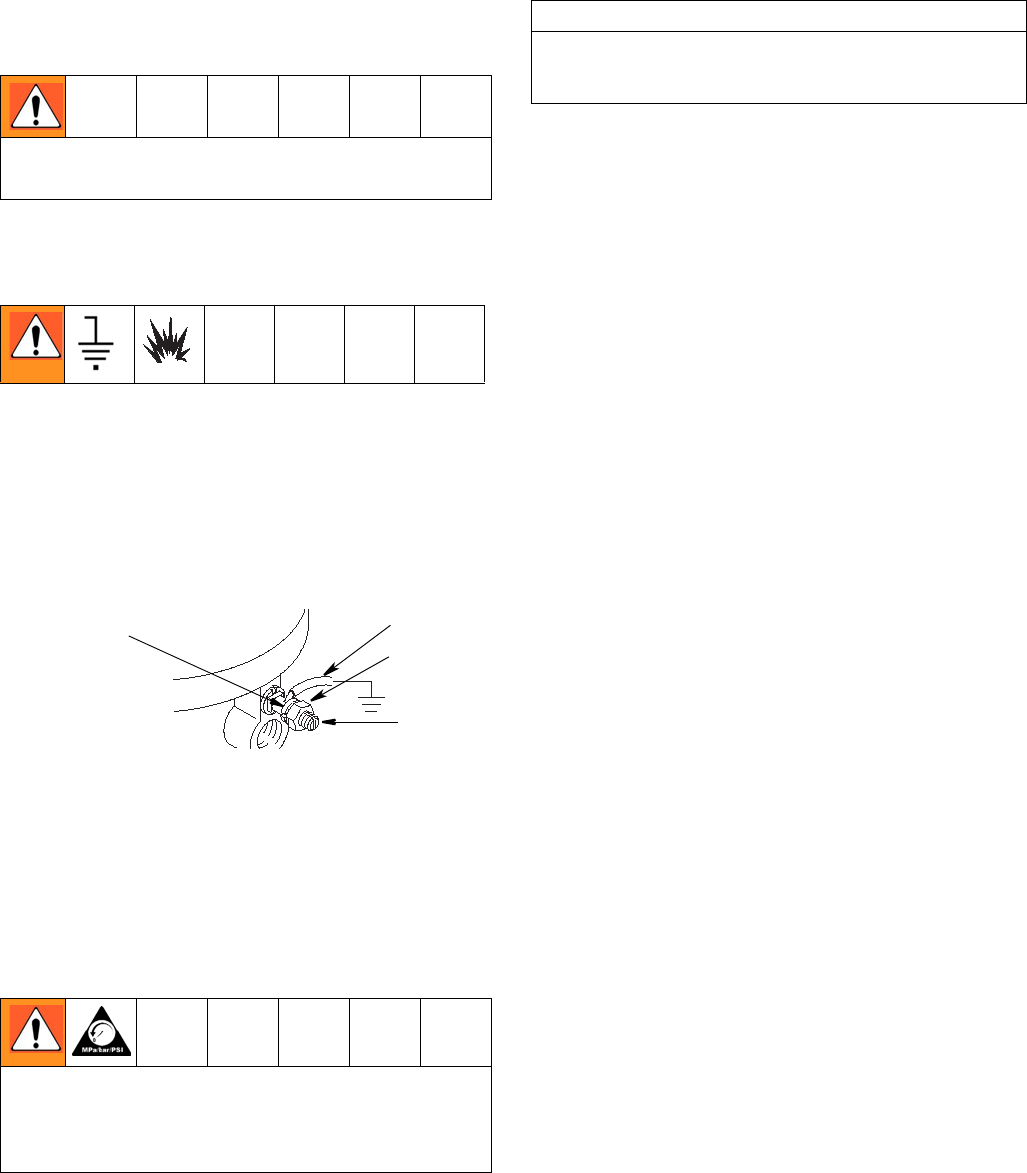

Grounding (for non-mobile installation)

(See FIG. 3 below)

1. Loosen grounding lug locknut (A) and washer (B).

2. Insert one end of a 12 gage (1.5 mm

2

) minimum

ground wire (C) into slot in lug (D). Tighten locknut

securely.

3. Connect other end of wire to true earth ground. To

order a ground wire and clamp, order part number

222011.

F

IG. 3

Pump Module

(See FIG. 4, page 8)

Mount Reservoir (P) on sturdy, flat surface with 6 (six),

3/8-inch diameter bolts. Note location of Fill Port (K),

Hydraulic Lines (A) and Lubricant Outlet Connection (C)

for easy access once installed.

1. Install Ball Valve (AA) (user provided) in the 3/8-inch

High Pressure Hydraulic Line (X).

2. Connect the 3/8-inch High Pressure Hydraulic Line

(X) to the High Pressure Hydraulic Connection

swivel (Y).

3. Connect the 3/4-inch Hydraulic Tank Line (T) to the

Tank Hydraulic Connection swivel (Z).

4. Connect the 24 VDC timer controlled signal to the

3-way Solenoid Valve (F).

5. Connect High Pressure Lubricant Supply Line (G) to

the Lubricant Output Connection (C) for Single Line

Parallel Systems or to Pressure Relief Kit Output

Connection for Single Line, Series

Progressive-based Systems.

6. Ground system (see GROUNDING). Mount

Reservoir (P) to grounded chassis member.

Vent Valve Kit for Custom Tank Installation

(Unless otherwise indicated, see FIG. 5 and FIG. 6, page

9)

1. Weld the bracket (F

IG. 7, page 10) in place per

recommended configuration for mounting the vent

valve. Paint the bracket if desired.

2. Connect the Hydraulic Control Line (A) to control

module Vent Valve Hydraulic Control (J).

3. Connect Pump Output Connection line (C) to Pump

outlet.

4. Connect the High Pressure Lubricant Supply Line

(G, F

IG. 4, page 8) feeding the injector system to the

Lubricant Output (E).

5. Connect the Vent Line (F) to Custom Tank (user

provided).

• Be sure unit is securely mounted before operation.

• Do not lift pressurized equipment.

• The hydraulic system must be depressurized before con-

necting High Pressure Hydraulic Lines (A).

• Be sure Breather (M) is not plugged before filling Reser-

voir (P).

A

CB

D

ti0720

CAUTION

The hydraulic supply must be 10µ filtered or better and sup-

ply 0.5 - 3.0 gpm (1.9 - 11.4 lpm) at 300 psi - 3500 psi (21

bar - 241 bar (2.1 MPa - 24 MPa).