Unpacking

4 312349G

Unpacking

The Dyna-Star pump module was carefully packaged for

shipment by Graco. When the package arrives, perform

the following procedure to unpack the units:

1. Inspect the shipping box carefully for shipping

damage. Contact the carrier promptly if damage is

discovered.

2. Unseal the box and inspect the contents carefully.

There should not be any damaged parts.

3. Compare the packing slip against all items included

in the box. Any shortages or other inspection

problems should be reported immediately.

4. Store the box and packing materials in a safe place

for future use. Graco recommends that all packing

materials be saved in case the unit needs to be

shipped again.

Pump Module Overview

Pump Module Capabilities

Pump Modules 247444 and 247574 for

Injector-based, Automatic Lubrication Systems:

provide lubricant flow and pressure to operate a single

line parallel automatic lubrication system. The module

requires a hydraulic power supply and a timed signal

from a lubrication controller. Based on these signals, the

pump module provides lubricant flow and pressure to

operate the injectors and vents the injector system to

reset the injectors.

Pump Modules 247706 and 247707 for Single Line,

Series Progressive-based, Automatic Lubrication

Systems: provide lubricant flow and pressure to

operate a single line, series progressive, automatic

lubrication system. The module requires a hydraulic

power supply and a timed signal from a lubrication

controller.

Pump Module Operation

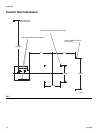

(See FIG. 4, page 8)

Cycles for Pump Modules 247444 and 247574 for

injector-based, Automatic Lubrication Systems

1. Upon receiving a signal from a 24-volt Lubrication

Controller (J), the 3-way Solenoid Valve (F) opens,

starting the Pump (D) and closes the Vent Valve (U).

2. The pump builds pressure until the pressure switch

in the system sends a signal to the Lubrication

Controller (J), ending the cycle or Pump (D) stalls.

3. The Lubrication Controller (J) terminates the 24-volt

signal to the 3-way Solenoid Valve (F).

4. The 3-way Solenoid Valve (F) closes, stopping the

Pump (D) and opening the Vent Valve (U) into the

Reservoir (P).

5. The Pressure Reducing Valve (S) and Flow Control

Valve (N) control the pump output pressure and

cycle rate.

Cycles for Pump Modules 247706 and 247707 for

Single Line, Series Progressive-based, Automatic

Lubrication Systems

1. Upon receiving a signal from the 24-volt Lubrication

Controller (J), the 3-way Solenoid Valve (F) opens;

starting the Pump (D).

2. The Pump (D) provides lubricant flow and pressure

until the Lubrication Controller (J) terminates the

signal to the 3-way Solenoid Valve; stopping the

Pump.

3. The Pressure Reducing Valve (S) and Flow Control

Valve (N) control the pump output pressure and

cycle rate.