20 307843

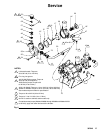

Service

Repairing the Air Control Valve

NOTE: Air Valve and Pilot Valve Repair Kit 220656 is

available. See page 38 to order. Parts included in the

kit are marked with an asterisk, for example, (40p*).

Use all the parts in the kit for the best results.

Disassembly

1. Relieve the pressure.

WARNING

PRESSURIZED EQUIPMENT HAZARD

To reduce the risk of a serious injury whenever you

are instructed to relieve pressure, follow the Pres-

sure Relief Procedure on page 10.

2. Cut a small slit in the tube ends (72*, 42*, 40p*)

and disconnect them from the pilot valve fittings

(5h), air valve tees (40n), and barb fittings (40s).

See Fig. 8.

3. Remove the valve end housings (40b) by unscrew-

ing the screws (40k) and nuts (40m).

4. Center the valve spools (40c) in the housing (40a).

Remove the spools and stem (40d) by applying

opposing force with wrenches on the spool (40c)

flats.

5. If the air filter (40q) needs cleaning or replace-

ment, unscrew the filter housing (40r) and remove

the filter. To clean them, soak the filter housing and

the filter in solvent until they are clean. Blow them

dry with low pressure air [under 30 psi (207 MPa,

2.1 bar)]. Press fit the filter into the housing, using

40 to 60 lb (18 to 27 kg) of force. Refer to Fig. 8.

Apply sealant to the filter housing threads and turn

it into the center housing (40a).

Assembly

1. Apply lithium-base grease to all o-rings, u-cups,

gaskets and to the complete spool assembly be-

fore installing them.

2. Remove the seal retainers (40e) from each side of

the center housing (40a). Replace the u-cup (40j*),

with the lips facing into the housing. Install the re-

tainers with the flat side facing into the housing.

3. Replace the spools (40c) if damaged. Replace the

o-ring (40h*) and u-cup (40i*) on each spool, being

sure to seat them in the grooves. Install the u-cup

with the lips facing towards the housing (40a).

4. Apply medium strength thread sealant to the spool

stem (40d) threads. Remove the excess sealant.

5. Thread one spool (40c) onto the stem (40d) and

insert it into the center housing (40a); be careful

not to dislodge the u-cups (40j) and retainers

(40e). Thread the other spool onto the stem. With

wrenches on the flats of the spools, apply oppos-

ing force and tighten until snug; 7 to 13 in-lb (0.79

to 1.47 NSm). Do not overtighten.

CAUTION

Do not overtighten the spools (40c) as this can

shear the spool threads.

6. Replace the gasket (40f*) in each end housing

(40b) and the o-ring (40g*) on each end housing

shoulder.

7. With the mufflers facing down, install the end

housings (40b), onto the center housing (40a); be

careful not to move the spool and dislodge the u-

cups (40j) and retainers (40e). Secure the end

housings with the four screws (40k) and nuts

(40m), torquing them to 2.2 to 3.7 ft-lb (3 to 5

NSm).

CAUTION

If mufflers (38) are replaced, they must be installed

with the lock rings (39) to avoid damage to the spool

and o-rings during operation.

8. Replace the two o-rings (40h*) in the center hous-

ing (40a).

9. Install the air valve on the pump with the four cap

screws (43). Torque them alternately and evenly to

2.2 to 3.7 ft-lb (3 to 5 NSm).

10. Connect the new tubes (72*, 42*, 40p*) to the pilot

valve fittings (5h), air valve tees (40n), and barb

fittings (40s), as shown in Fig. 8.