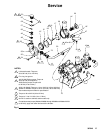

16 307843

Service

Assembly

1. Slide the retaining plate (20), bellows (14*), and

intake housing (36) onto the piston shaft (15). Do

not force the bellows. Repeat on the other side.

CAUTION

To avoid damaging the bellows (14), do not force it

onto the shaft. The bellows will press into place when

the piston (17) is secured.

2. Install the piston (17) on the shaft (15) and secure

it with the screw (16). Repeat on the opposite end

of the pump.

3. Using a socket and breaker bar, torque one screw

(16) to 40 to 50 ft-lb (54 to 67 NSm), then repeat

with the other screw.

4. Grease and install an o-ring (19*) in each inlet.

Install inlet manifold (47) with screws (32) and

washers (46 or 61). Don’t torque screws yet.

CAUTION

To avoid loosening the piston stud (30) during disas-

sembly, do not overtighten the screws (16).

NOTE: If using a formed UHMWPE seal, proceed to

step 5. If using a flat nylon seal, proceed to step 6.

5. Grease and install the o-ring (18*) in the groove in

the tapered side of the retaining plate (12). Grease

the outlet housing (33) and install the piston seal

(13*) and retaining plate (12). Be sure the flat side

of the retaining plate faces the piston seal. Secure

with the four screws (34) and washers (35).

6. Apply 10 psi air to move the piston to one side and

hold it there. Replace the o–ring (18*) in the

groove in the tapered side of the retaining plate

(12).

Grease the oulet housing groove and set the nylon

seal (13) inside the groove. Carefully tip the hous-

ing (33) onto the inlet housing. Be sure the flat side

of the retaining plate (12) faces the piston seal.

Secure with the four screws (34) and washers

(35).

Increase the air pressure to about 50 psi until the

pump cycles and the piston drives to the other

side.

Reduce the air pressure to 10 psi to hold in posi-

tion. Repeat the seal installation pattern.

Increase the air pressure to 50 psi again to cause

the pump to cycle again and form the seal on the

first side.

NOTE: Torque the screws, on 400 and 1200 Series

pumps, to 40 to 50 ft-lb (54 to 68 N-m). Torque the

screws on the 2500 Series pump, to 35 to 40 ft-lb (47

to 54 N-m).

7. Torque the inlet manifold screws (32) to 7.4 to 12.5

ft-lb (10 to 17 N-m).

8. Replace the o-ring (52*) in each outlet manifold

connector (51) and lubricate the threads. Install the

outlet manifold (50), torquing the connectors to 55

to 85 ft-lb (75 to 115 NSm).

NOTE: On stainless steel pumps (Models 220666

through 220668 and Models 237011 to 237013), apply

anti-seize lubricant to the threads of the connector

(51).