NOTE: System operating pressures must be near

normal before valve can shift.

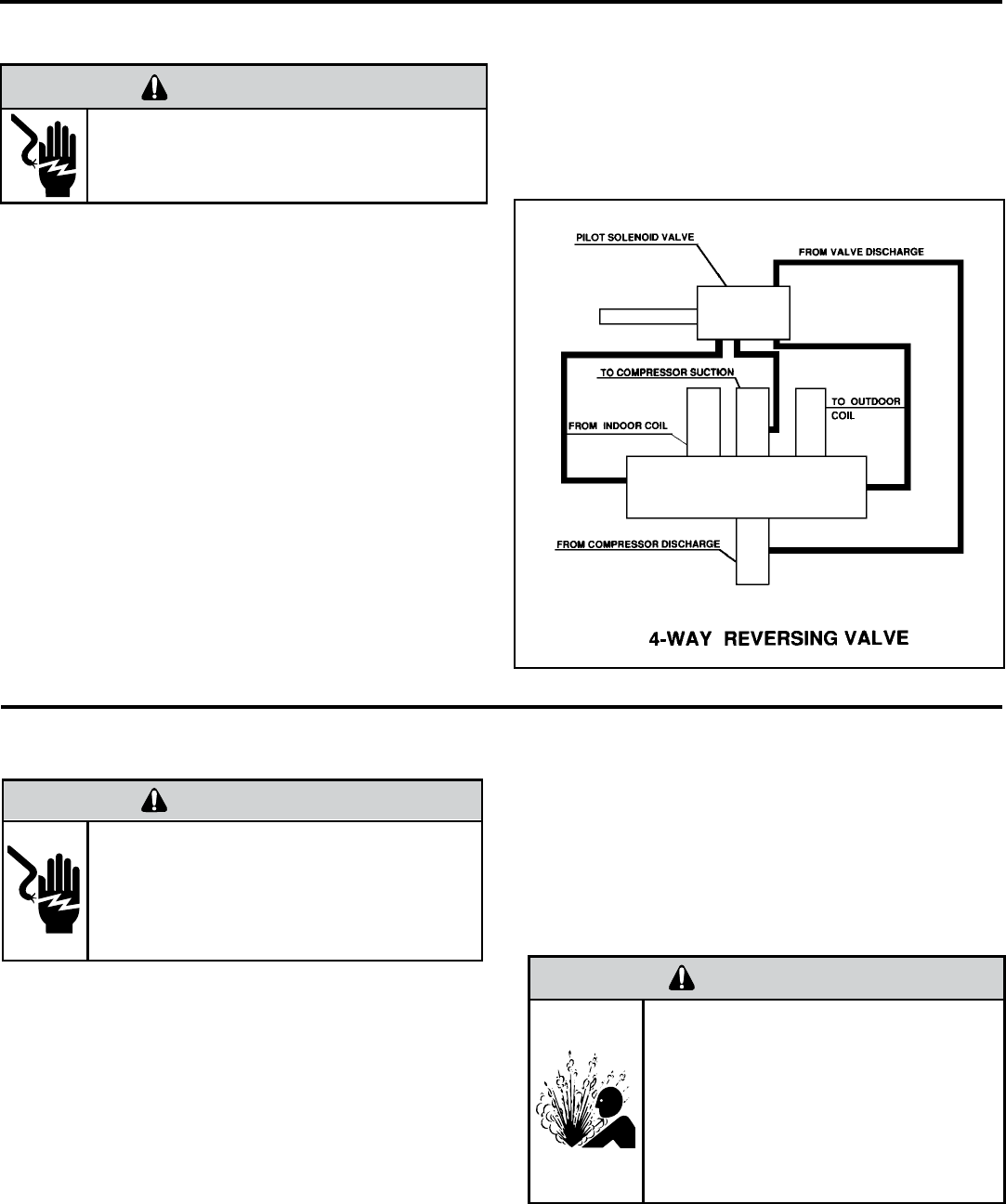

REVERSING VALVE DESCRIPTION/OPERATION

The Reversing Valve controls the direction of refrigerant fl ow

to the indoor and outdoor coils. It consists of a pressure-

operated, main valve and a pilot valve actuated by a solenoid

plunger. The solenoid is energized during the heating cycle

only. The reversing valves used in the PTAC system is a

2-position, 4-way valve.

The single tube on one side of the main valve body is the

high-pressure inlet to the valve from the compressor. The

center tube on the opposite side is connected to the low

pressure (suction) side of the system. The other two are

connected to the indoor and outdoor coils. Small capillary

tubes connect each end of the main valve cylinder to the “A”

and “B” ports of the pilot valve. A third capillary is a common

return line from these ports to the suction tube on the main

valve body. Four-way reversing valves also have a capillary

tube from the compressor discharge tube to the pilot valve.

The piston assembly in the main valve can only be shifted

by the pressure differential between the high and low sides

of the system. The pilot section of the valve opens and

closes ports for the small capillary tubes to the main valve

to cause it to shift.

ELECTRIC SHOCK HAZARD

WARNING

Disconnect power to the unit before servicing.

Failure to follow this warning could result in

serious injury or death.

TESTING THE COIL

The solenoid coil is an electromagnetic type coil mounted

on the reversing valve and is energized during the

operation of the compressor in the heating cycle.

1. Turn off high voltage electrical power to unit.

2. Unplug line voltage lead from reversing valve coil.

3. Check for electrical continuity through the coil. If you

do not have continuity replace the coil.

4. Check from each lead of coil to the copper liquid line

as it leaves the unit or the ground lug. There should

be no continuity between either of the coil leads

and ground; if there is, coil is grounded and must be

replaced.

5. If coil tests okay, reconnect the electrical leads.

6. Make sure coil has been assembled correctly.

ELECTRIC SHOCK HAZARD

WARNING

Unplug and/or disconnect all electrical power

to the unit before performing inspections,

maintenances or service.

Failure to do so could result in electric shock,

serious injury or death.

NOTE: Do not start unit with solenoid coil removed from

valve, or do not remove coil after unit is in operation. This

will cause the coil to burn out.

CHECKING THE REVERSING VALVE

NOTE: You must have normal operating pressures before

the reversing valve can shift.

Check the operation of the valve by starting the system

and switching the operation from “Cooling” to “Heating”

and then back to “Cooling”. Do not hammer on valve.

Occasionally, the reversing valve may stick in the heating

or cooling position or in the mid-position.

Sealed Refrigeration System contains refrigerant

and oil under high pressure.

Proper safety procedures must be followed,

and proper protective clothing must be worn

when working with refrigerants.

Failure to follow these procedures could

result in serious injury or death.

WARNING

HIGH PRESSURE HAZARD

34