32

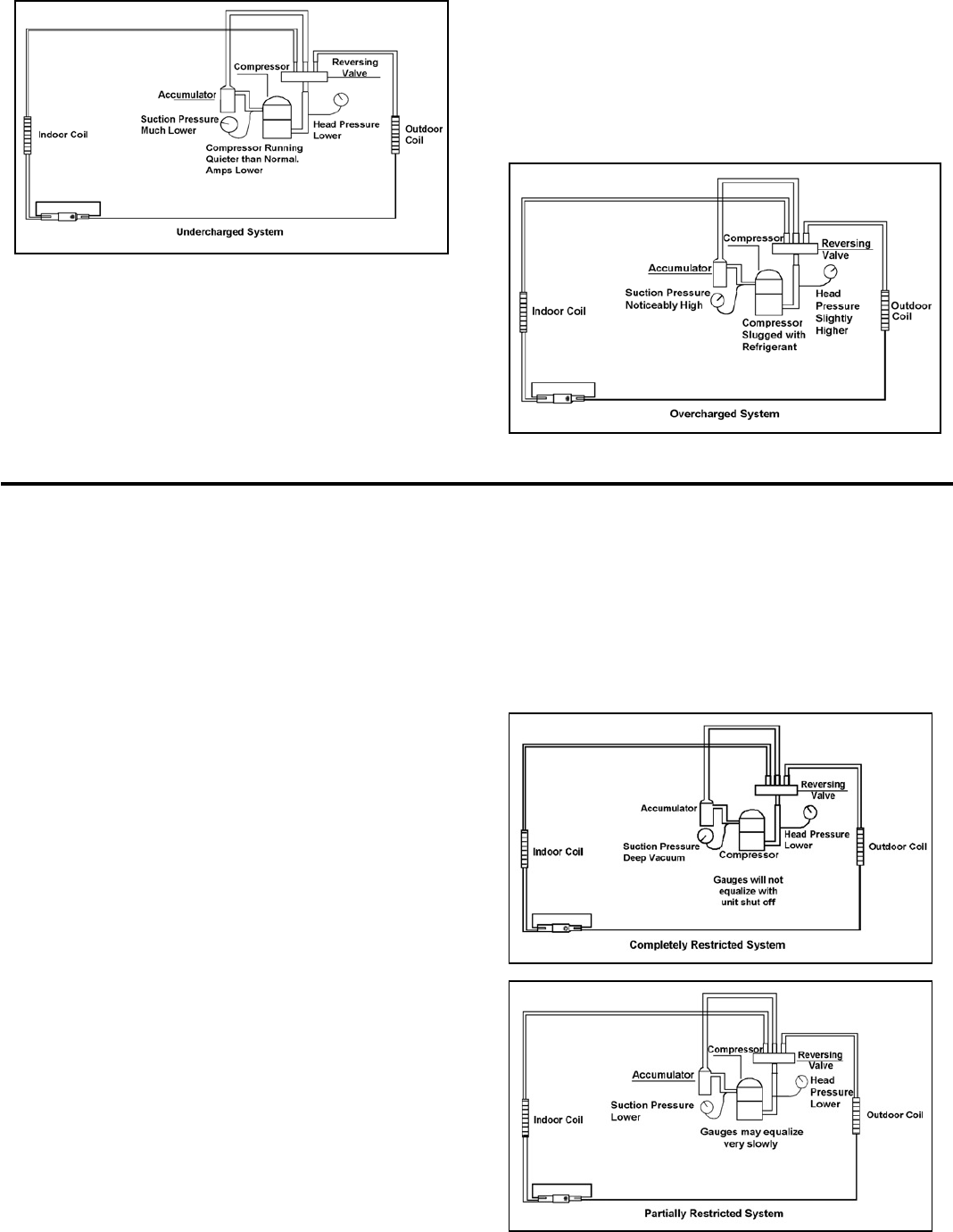

Overcharged Refrigerant Systems

After the unit has run 10 to 15 minutes, check the gauge

pressures. Gauges connected to system with an undercharge

will have low head pressures and substantially low suction

pressures.

Improper air fl ow over the evaporator coil may indicate

some of the same symptoms as an over charged system.

An overcharge can cause the compressor to fail, since it

would be “slugged” with liquid refrigerant.

The charge for any system is critical. When the compressor

is noisy, suspect an overcharge, when you are sure that the

air quantity over the evaporator coil is correct. Icing of the

evaporator will not be encountered because the refrigerant

will boil later if at all. Gauges connected to system will usually

have higher head pressure (depending upon amount of over

charge). Suction pressure should be slightly higher.

Compressor amps will be near normal or higher.

Noncondensables can also cause these symptoms. To

confi rm, remove some of the charge, if conditions improve,

system may be overcharged. If conditions don’t improve,

Noncondensables are indicated.

Whenever an overcharged system is indicated, always make

sure that the problem is not caused by air fl ow problems.

Restricted Refrigerant System

Troubleshooting a restricted refrigerant system can be

diffi cult. The following procedures are the more common

problems and solutions to these problems. There are two

types of refrigerant restrictions: Partial restrictions and

complete restrictions.

A partial restriction allows some of the refrigerant to

circulate through the system.

With a complete restriction there is no circulation of

refrigerant in the system.

Restricted refrigerant systems display the same symptoms

as a “low-charge condition.”

When the unit is shut off, the gauges may equalize very

slowly.

Gauges connected to a completely restricted system will

run in a deep vacuum. When the unit is shut off, the gauges

will not equalize at all.

A quick check for either condition begins at the evaporator.

With a partial restriction, there may be gurgling sounds

at the metering device entrance to the evaporator. The

evaporator in a partial restriction could be partially frosted

or have an ice ball close to the entrance of the metering

device. Frost may continue on the suction line back to the

compressor.

Often a partial restriction of any type can be found by feel,

as there is a temperature difference from one side of the

restriction to the other.

With a complete restriction, there will be no sound at the

metering device entrance. An amperage check of the

compressor with a partial restriction may show normal

current when compared to the unit specifi cation.

With a complete restriction the current drawn may be

considerably less than normal, as the compressor is

running in a deep vacuum (no load.) Much of the area of

the condenser will be relatively cool since most or all of the

liquid refrigerant will be stored there.

The following conditions are based primarily on a system

in the cooling mode.