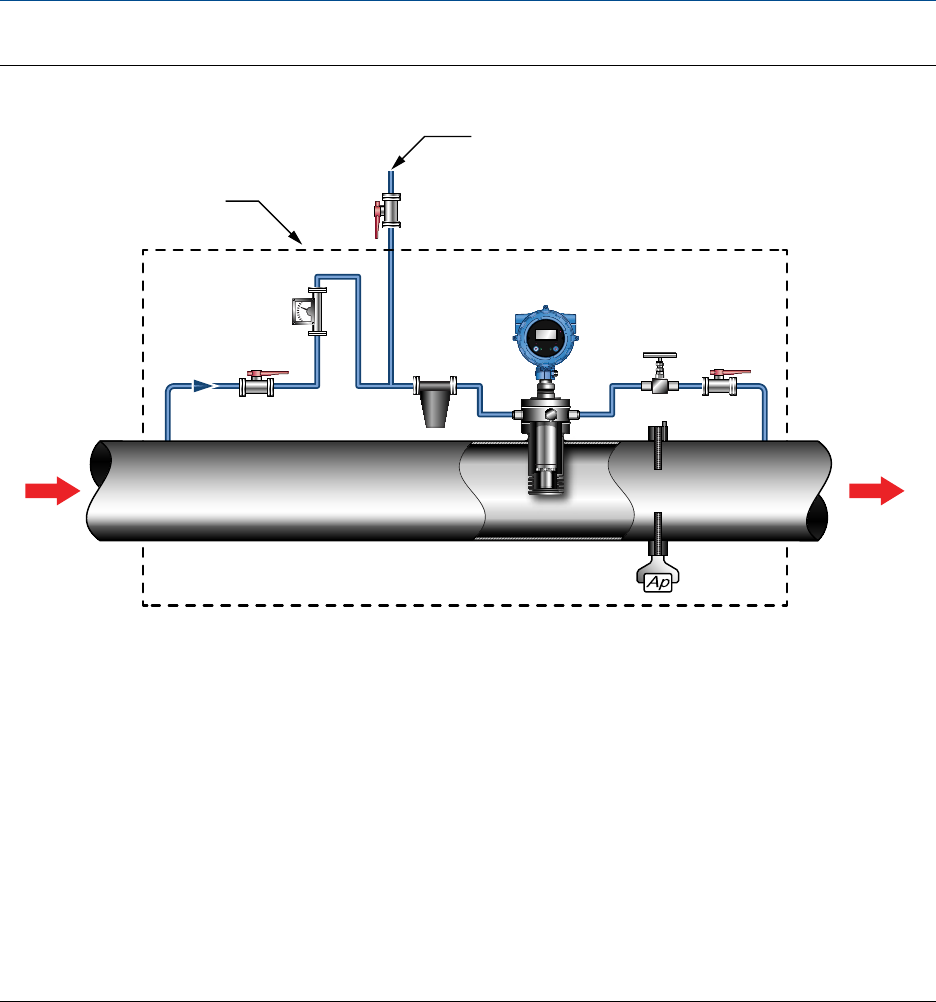

Meter installation in differential pressure applicationFigure 1-6:

STATUS

SCROLL SELECT

E

A

A

B

D

C

F

G

H

GDM

A. Meter isolation valves

B. Flowmeter

C. Venting valve

D. Flow control needle valve

E. Filter

F. Differential pressure transmitter

G. Thermal insulation

H. Vent/vacuum test point

Note

Do not insulate the transmitter (electronics) and maintain a nominal 1-in clearance between the insulation and the transmitter

housing.

With the differential pressure installation method:

• The process gas flow bypasses the meter, but should be low enough [for example,

5 lt/hrs (0.176 ft

3

/hr)] to not be of significance.

• The measured density is the upstream density.

• The control valve and the flowmeter can be mounted on either side of the meter to

suit the installation and dependent on where the density point is.

Planning

10 Micro Motion

®

Gas Density Meters