17. Reinstall the switch housing assembly by passing the

wires from the motor shaft through the collar, screw

the assembly onto the motor shaft (Figure 11).

Tighten the setscrew using the 5/32” hex wrench

(supplied). Engage the connector from the switch

housing to the motor connector. The two connectors

are keyed and must be mated correctly before they

can be engaged.

6

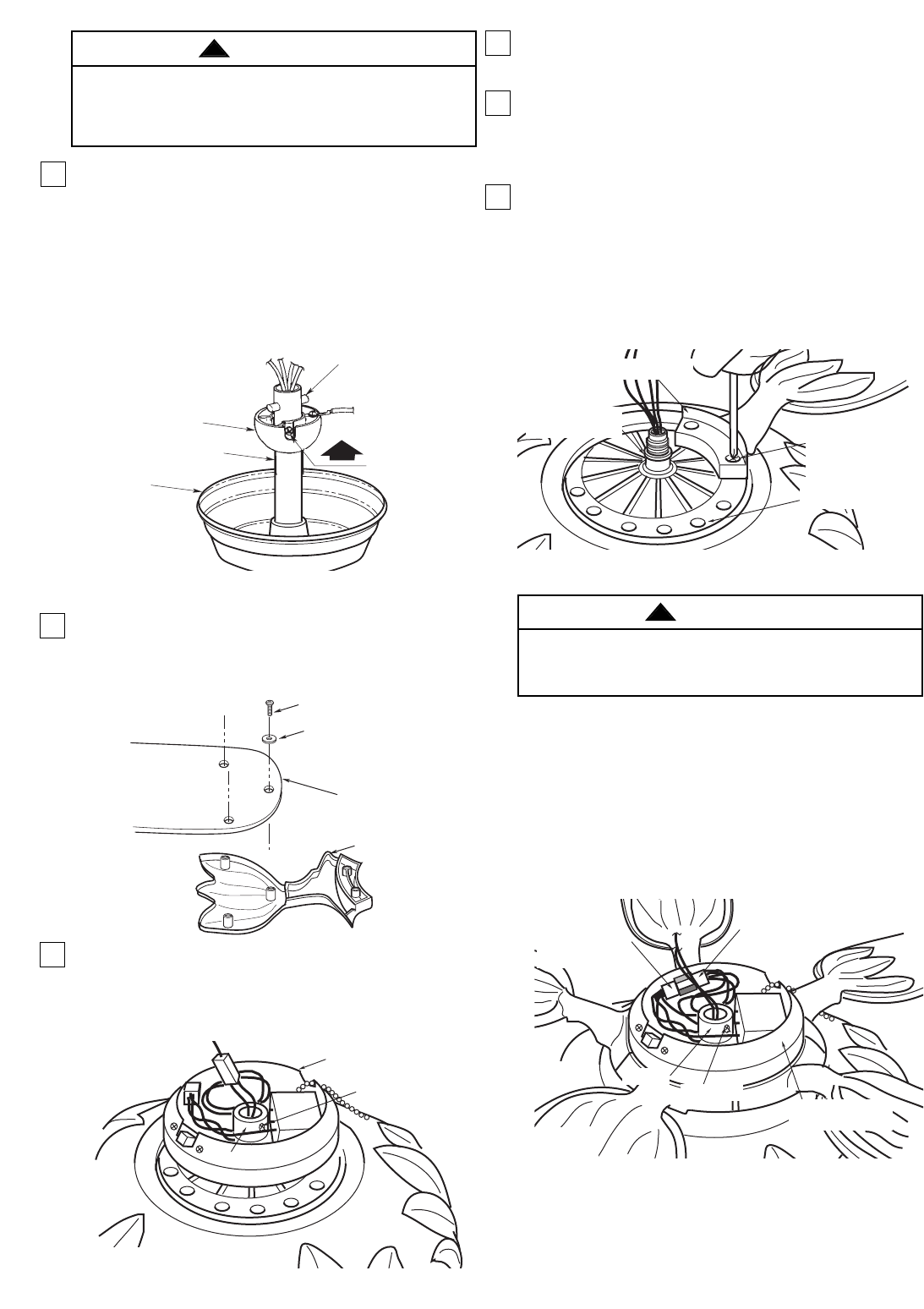

11. Reinstall the hanger ball on the downrod as

follows. Route the motor leads through the hanger

ball and slide the hanger ball over the downrod

(Figure 7). Install the pin through the holes at the

top of the downrod and slide the hanger ball up

the downrod, aligning the ball so the pin is

captured in the groove in the top of the hanger

ball. Pull the hanger ball up tight against the pin

and securely tighten the setscrew in the hanger

ball. A loose setscrew could create fan wobble.

12. Use three 10-24 x 3/8" pan head screws and flat

washers (supplied) to secure flange to blade

(blades ordered separately) (Figure 8). Repeat for

the remaining four blades.

13. Using the 5/32” hex wrench (supplied), loosen the

setscrew in the collar and unscrew (counterclock-

wise) the switch housing assembly from the motor

shaft (Figure 9). Do NOT remove the flat washer

from the motor shaft.

SETSCREW

DOWNROD

PIN

HANGER BALL

CEILING COVER

Figure 7

10-32 X 5/8"

OVAL HEAD SCREW

(3 PER BLADE

ASSEMBLY)

MOTOR HUB

BLADE FLANGE

FLAT WASHER

(DO NOT REMOVE)

FLAT WASHER (3)

BLADE

10-24 x 3/8" PAN HEAD

SCREW (3)

BLADE FLANGE

Figure 8

SWITCH HOUSING ASSEMBLY

SETSCREW

COLLAR

Figure 9

Figure 10

14.Use the 10 round recessed holes in the motor hub

marked with "5" and install the five blade assemblies

in accordance with Step 15.

15. Loosely attach one blade assembly to the motor

hub using two 10-32 x 5/8" oval head screws

(supplied) (Figure 10). Make sure the screws are

NOT tightened at this time. Repeat this procedure

for the four remaining blade assemblies.

16.The blade flanges have an interlocking feature that

must be fully engaged before tightening the

screws. Make sure all the flanges are properly

engaged and then tighten the flange screws In a

clockwise sequence. If one of the flanges does not

seat properly on the motor hub, loosen the

adjacent flange screws, re-engage and reseat the

flanges, then tighten the screws again.

MOTOR

CONNECTOR

SWITCH HOUSING

CONNECTOR

SWITCH HOUSING

ASSEMBLY

SETSCREW

COLLAR

Figure 11

It is critical that the pin in the hanger ball is properly

installed and the setscrew securely tightened.

Failure to verify that the pin and setscrew are

properly installed could result in the fan falling.

WARNING

!

To reduce the risk of personal injury, do not bend the

blade flanges when installing the flanges, balancing

the blades, or cleaning the fan.

WARNING

!