17

Diagnostics and Troubleshooting

Analog Outputs

The drive has two 10 bit Analog Outputs which may be used for diagnostics, monitoring or

control purposes. These outputs are referred to as Channel 1 and Channel 2. They can be

accessed from the command connector on the drive or from the diagnostics output pins

located on the front of the drive.

Each Channel provides a programmable Analog Output Source. (In early releases, the FM-3

analog output is fixed at the default selections.)

Default Analog Output Source:

• Channel 1 = Velocity Feedback

• Channel 2 = Torque Command

Each channel includes a programmable Analog Output Offset and an Analog Output Scale.

This feature allows you to “zoom in” to a desired range effectively increasing the resolution.

The units for both of these parameters is dependent upon the Analog Output Source selection.

Analog Output Offset units:

• Velocity Feedback = RPM

• Torque Command = Percent of continuous torque

Analog Output Scale units:

• Velocity Feedback = RPM/volt

• Torque Command = Percent of continuous torque/volt

Example:

You could use the Analog Outputs to accurately measure velocity overshoot. For example, to

measure a target velocity of 2000 RPM at a resolution of ±10V = ±200 RPM do the following.

1. Selected Velocity Feedback for the Analog Output Source.

2. Set the Analog Output Offset to 2000 RPM.

3. Set the Analog Output Scale to 20 RPM/VOLT.

This will provide an active range from -10 to +10 Volts to represent 1800 to 2200 RPM.

Therefore, the measured resolution has been increased.

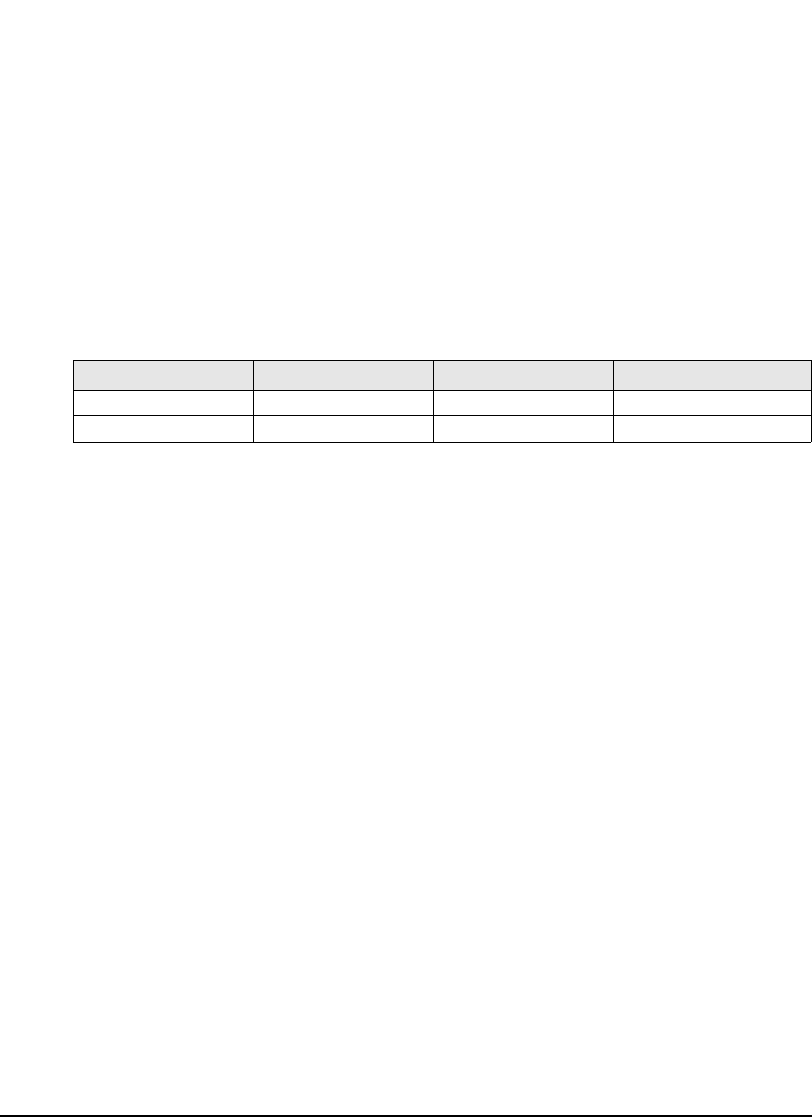

Output Source Offset Scale

1 Velocity Feedback 0 600 RPM/volt

2 Torque Command 0 30% /volt