INSTRUCTIONS FOR LIFTING AND MOVING OVEN

ATTENTION: Only proper heavy lifting

machinery and handling equipment should be

used for unloading, moving and installing the

oven. This duty should be performed by

professionals trained in this kind of work.

Improper handling of the equipment could result

in damaging the oven or personal injury.

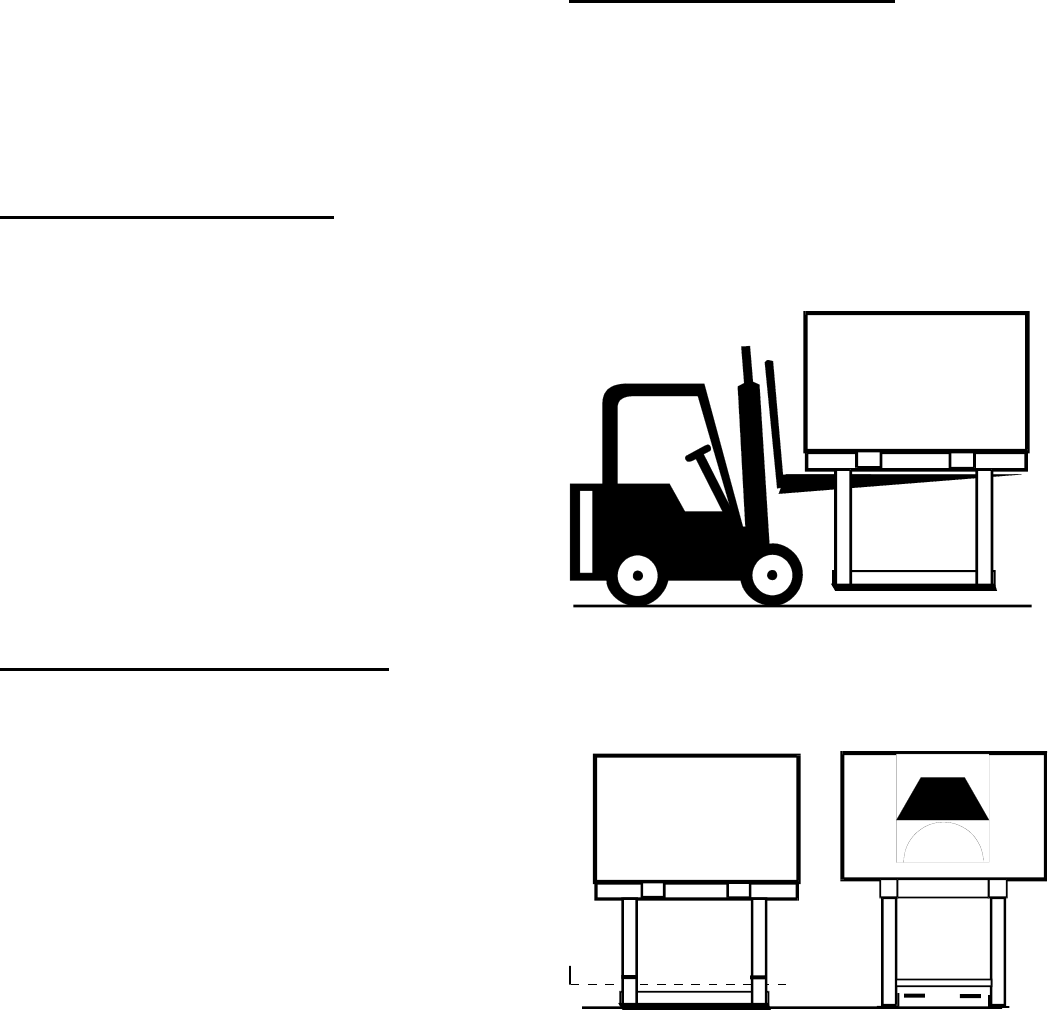

1- USING A FORKLIFT

Determine if forklift capacity is sufficient to lift

oven. (6000 lb for models 90 and 110, and

8000 lb for models 130 and 160)

Prior to lifting, make sure forks are long enough

to reach both horizontal steel tubes on

underside of oven (Without touching oven

shell). Approach oven from front entrance side

or rear side. Keep forklift straight. Carefully

place forks through inside of tube steel supports

legs and position under horizontal tube steel

members. Slowly lift and move oven as

needed. (See dia. A)

2- USING A PALLET JACK

Determine if pallet jack capacity is sufficient to

lift oven. (4500 lb for models 90, 110, 130 and

6000 lb for model 160)

Prior to lifting, make sure pallet jack is long

enough to reach both horizontal angles at lower

end of steel tube support legs. Place pallet jack

between tube steel support legs under

horizontal angles. (See dia. B) Carefully lift

oven and move slowly.

CAUTION: OVEN IS TOP HEAVY MOVE

WITH CARE.

3- INSTALLING OVEN

Slowly lower oven into proper location. Oven

should be set on a level floor. Shim as

necessary to assure that oven is level. Remove

horizontal front angle when oven is in place.

Insert ramset red heads, min. of 3 inches in

length, through base plates. (See fig 17-A pg. 7

in installation instructions)

DIA. A

DIA. B