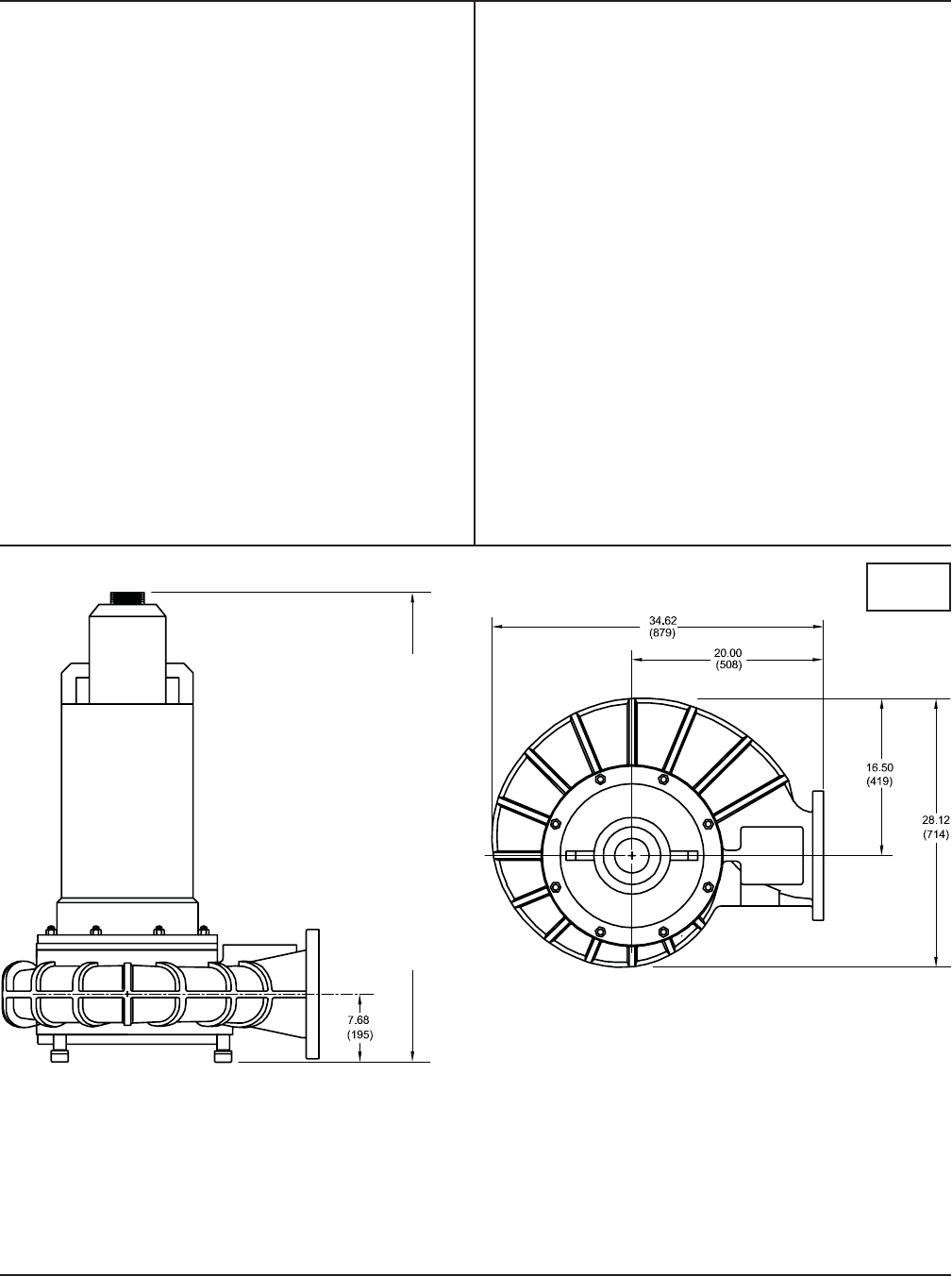

4

DISCHARGE ......................8” NPT, 125 lb. Flange Horizontal

LIQUID TEMPERATURE ...104°F (40°C) Continuous

VOLUTE .............................Cast Iron ASTM A-48, Class 30

with Cast Iron Wear Ring

MOTOR HOUSING .............Cast Iron ASTM A-48, Class 30

SEAL PLATE ......................Cast Iron ASTM A-48, Class 30

IMPELLER:

Design ....................3 Vane, Enclosed with Bronze wear

ring and pump out vanes on back

side. Dynamically Balanced ISO

G6.3

Material .................Cast Iron ASTM A-48, Class 30

SHAFT ............................... 416 Stainless Steel

SQUARE RINGS.................Buna-N

HARDWARE .......................300 Series Stainless Steel

LIFTING CHAIN ..................Yoke, Galvanized

PAINT ...............................Air Dry Enamel.

SEAL: Design ...................Tandem Mechanical, Oil Filled

Reservoir.

Material ..................Rotating Faces - Carbone

Stationary Faces - Ceramic

Elastomer - Buna-N

Hardware -300 Series Stainless

CORD ENTRY .....................25 ft. (7.6 m) Std. Cord. Epoxy

Sealed Housing with Secondary

Pressure Grommet for Sealing and

Strain Relief

SPEED ...............................870, 1150, 1750 RPM (Nominal)

UPPER BEARING:

Design .................... Single Row, Ball, Grease Lubricated

Load ...................... Radial

LOWER BEARING:

Design .....................Double Row, Ball, Grease Lubricated

Load ....................... Radial & Thrust

MOTOR: Design .................NEMA B, Three Phase Torque Curve

Air-Filled, Squirrel Cage Induction

“UL” Listed for Class I, Groups C &

D, Division 1, Explosion Proof

Insulation ..............Class F.

SINGLE PHASE ................Capacitor Start/Induction Run.

Start Capacitors included with

pump assembly. Controls require

external overload protection.

THREE PHASE .................Dual Voltage 230/460; Requires

Overload Protection to be Included

in control panel.

MOISTURE SENSOR .......Normally Open (N/O), Requires

Relay in Control Panel

TEMP SENSOR ................Normally Closed (N/C), Requires

Relay in Control Panel

OPTIONAL EQUIPMENT: Seal Material, Impeller Trims,

Additional Cord

SECTION: A - PUMP SPECIFICATIONS

inches

(mm)

IMPORTANT !

1.) MOISTURE AND TEMPERATURE SENSORS MUST BE CONNECTED TO VALIDATE THE UL LISTING.

2.) A NON-SPARKING BREAK AWAY FITTING MUST BE USED TO VALIDATE THE UL LISTING.

3.) A SPECIAL MOISTURE SENSOR RELAY IS REQUIRED IN THE CONTROL PANEL FOR PROPER OPERATION OF THE MOISTURE SENSORS.

CONTACT BARNES PUMPS FOR INFORMATION CONCERNING MOISTURE SENSING RELAYS FOR CUSTOMER SUPPLIED CONTROL PANELS.

4.) THESE PUMPS ARE UL LISTED FOR PUMPING WATER AND WASTEWATER. DO NOT USE TO PUMP FLAMMABLE LIQUIDS.

5.) INSTALLATIONS SUCH AS DECORATIVE FOUNTAINS OR WATER FEATURES PROVIDED FOR VISUAL ENJOYMENT MUST BE INSTALLED IN

ACCORDANCE WITH THE NATIONAL ELECTRIC CODE ANSI/NFPA 70 AND/OR THE AUTHORITY HAVING JURISDICTION. THIS PUMP IS NOT

INTENDED FOR USE IN SWIMMING POOLS, RECREATIONAL WATER PARKS, OR INSTALLATIONS IN WHICH HUMAN CONTACT WITH PUMPED

MEDIA IS A COMMON OCCURRENCE.

8XSE20048HA - 49.06 (1246)

8XSE20058HA - 49.06 (1246)

8XSE25048HA - 49.06 (1246)

8XSE25058HA - 49.06 (1246)

8XSE30048HA - 49.06 (1246)

8XSE30058HA - 49.06 (1246)

8XSE30046HA - 49.06 (1246)

8XSE30056HA - 49.06 (1246)

8XSE40046HA - 49.06 (1246)

8XSE40056HA - 49.06 (1246)

8XSE50046HA - 49.06 (1246)

8XSE50056HA - 49.06 (1246)

8XSE60046HA - 49.06 (1246)

8XSE60056HA - 49.06 (1246)

8XSE75046HA - 54.50 (1384)

8XSE75056HA - 54.50 (1384)

8XSE100044HA - 54.50 (1384)

8XSE100054HA - 54.50 (1384)

8XSE125044HA - 54.50 (1384)

8XSE125054HA - 54.50 (1384)

8XSE150044HA - 54.50 (1384)

8XSE150054HA - 54.50 (1384)