11

F-2.1) Disassembly and Inspection:

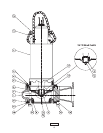

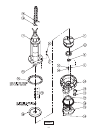

To expose outer shaft seal (13) for examination, remove

Impeller and Volute per Section F-1.1. Set motor assembly

(2) in the up position to prevent loss of oil. Remove snap

ring from motor shaft, then retaining ring (13D), spring (13C)

and rotating member (13B) from shaft, See Fig. 4. Examine

all seal parts and especially contact faces. Inspect seal for

signs of wear such as uneven wear pattern on stationary

members, chips and scratches on either seal face. DO NOT

interchange seal components, replace the entire shaft seal

(13). If replacing seal, remove stationary (13A) from mounting

plate by prying out with fl at screw driver.

F-2.2) Reassembly:

Lightly oil (DO NOT use grease) outer surface of stationary

member (13A). Press stationary member (13A) fi rmly into

mounting plate using a seal pusher, nothing but the seal

pusher is to come in contact with seal face (see Fig. 5).

IMPORTANT ! - DO NOT hammer on the seal

pusher- it will damage the seal face.

Make sure the stationary member is in straight and that

the rubber ring is not out of it’s groove. Lightly oil (DO NOT

use grease) shaft and inner surface of bellows on rotating

member (13B) see Fig. 6. With lapped surface of rotating

member (13B) facing inward toward stationary member

(13A), slide rotating member (13B) onto shaft using a seal

pusher, until lapped faces of (13A) and (13B) are together.

(see Fig. 4).

IMPORTANT! - It is extremely important to keep

seal faces clean during assembly. Dirt particles

lodged between these faces will cause the seal to

leak.

Place spring (13C) over shaft and in place on rotating

member (13B), making sure it is seated on retainer and not

cocked or resting on bellows tail. Slide retaining ring (13B)

over shaft and let rest on spring (13C). Assemble impeller

and volute as outlined in paragraph F-1.2.

F-3) Motor & Inner Shaft Seal Service

The XSE Submersible Pump motor is manufactured by

Reliance Electric Co. and must be serviced and repaired by

Reliance approved service centers only.

For lead reconnection information, contact Reliance Electric

Co., giving motor serial number.

WARNING ! - These motors are U/L Listed

for application in CLASS I, GROUPS C & D

EXPLOSION PROOF Environments. All repairs,

other than lead reconnects and outer seal

replacement, shall be performed by an authorized

reliance service facility. Any other repairs

performed by the customer or NON-RELIANCE

SERVICE Facilities negates the U/L Listing and

motor warranty.

SECTION: G REPLACEMENT PARTS

G-1 ORDERING REPLACEMENT PARTS:

When ordering replacement parts, ALWAYS furnish the

following information:

1. Pump serial number and date code. (Paragraph G-4)

2. Pump model number. (Paragraph G-3)

3. Pump part number. (Paragraph G-2)

4. Part description.

5. Item part number.

6. Quantity required.

7. Shipping instructions.

8. Billing Instructions.

G-2 PART NUMBER:

The part number consists of a six (6) digit number, which

appears in the catalog. A one or two letter suffi x may follow this

number to designate the design confi guration. This number is

used for ordering and obtaining information.

G-3 MODEL NUMBER:

This designation consists of numbers and letters which

represent the discharge size, series, horsepower, motor phase

and voltage, speed and pump design. This number is used for

ordering and obtaining information.

G-4 SERIAL NUMBER:

The serial number block will consist of a six digit number,

which is specifi c to each pump and may be preceded by

a alpha character, which indicates the plant location. This

number will also be suffi xed with a four digit number, which

indicates the date the unit was built (Date Code). EXAMPLE:

A012345 0490.

Reference the six digit portion (Serial Number) of this number

when referring to the product.

FIGURE 5

Stationary Member (13A)

Polished Face Out

Motor Mounting Plate

Seal Pusher

Rotating Member (13B)

Bullet

Reliance Motor

Seal Pusher

Stationary

FIGURE 6