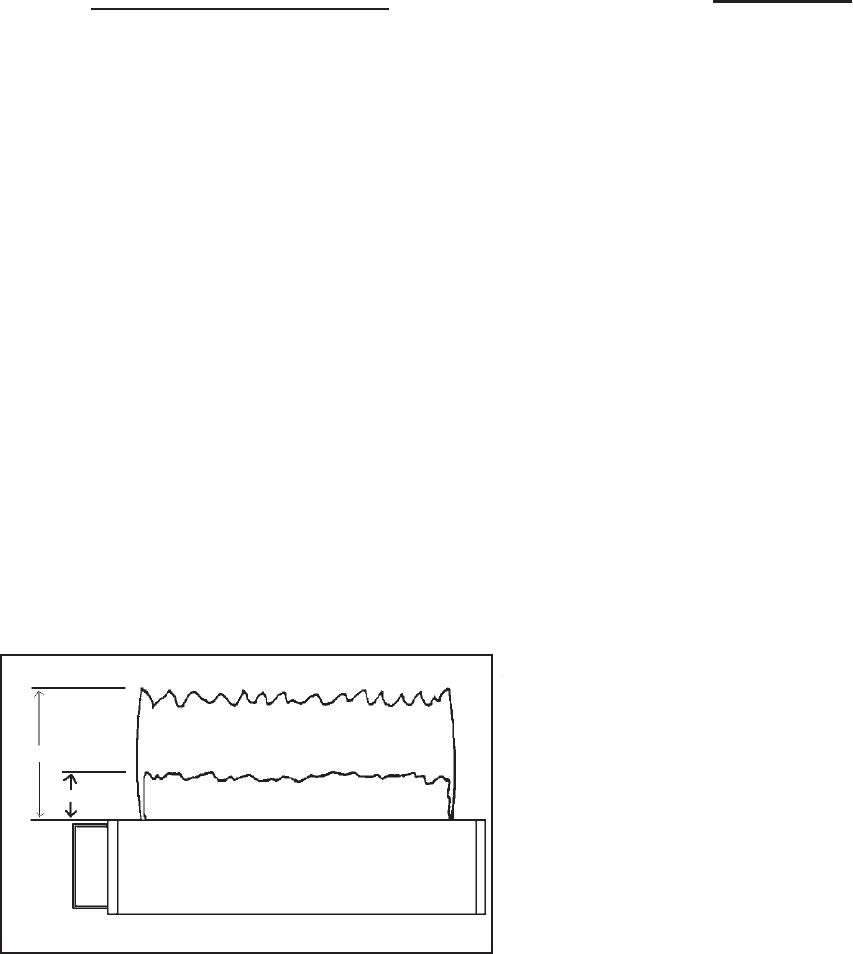

PROPER BURNER FLAME

A proper flame will have a dark blue inner mantle

that sits right on top of the burners with a lighter

blue outer mantle rising above the burner, (See

Figure 11). There may be some yellow where the

pilot flame and burner flame meet. There is no

primary air adjustment on the burner, and proper

flame is assured since the correct manifold pressure

and orificing has been done at the factory. NOTE:

It is advised that the burner flames be checked at

least twice during the heating season for any changes

in burner flame characteristics. The appliance area

must be kept clear and free from combustible

materials, gasoline, and other flammable vapors and

liquids. This heater comes from the factory with

the proper burner orifice for elevations up to 2,000

feet. Heaters installed above 2,000 feet must be

derated 4% for every 1,000 feet. For the proper

orifice size find the Model Number and elevation

on the orifice chart (See CONTROLS). Replace

burner orifice.

OPERATION

This heater is equipped with a slow opening gas control.

On a call for heat the gas valve does not snap-open to

full manifold pressure, but opens with a gradual increase

to normal manifold pressure. The time lapse from the

call for heat to normal operating pressure is two to five

seconds. The slow open feature assures a safe, less

noisy ignition.

After the heat exchanger has warmed sufficiently,

the fan will automatically come on to efficiently

transfer the heat into the room. NOTE: All but the

35,000 BTU unit (which is one speed) have an

automatic two-speed fan. In a new installation or

on fall start-up in a very cold room, some on-off

cycling of the fan may occur if the heat exchanger

cools too much. The burner, however, will continue

to operate and the fan cycle until the thermostat is

satisfied.

5” to 7”

Approx.

1”

FIGURE 11

Page 12