Installation l 3-15

3

Description

Testing the Installation

You have completed the HTC installation. Now it’s time to make sure everything

works.

1 Make sure there is no material in the hopper. If there is a loader or vacuum

receiver mounted on the hopper, disconnect the material inlet hose at the source.

2 Perform the following safety checks:

• Make sure all components are securely mounted;

• Make sure all hoses are connected to the proper locations and secured

with hose clamps;

• Make sure all sensors are properly installed and secured:

• Make sure all wiring is secure and away from potential mechanical dam-

age;

• Make sure the air filter is clean and has a minimum of 6 in. (15.2 cm)

clearance without any flow obstructions; and

• Make sure the hopper outlet is free from obstructions that would cause

back pressure in the drying hopper.

3 Perform a resistance test. Check the resistance leg to leg and leg to ground to

make sure that each heater and blower are wired correctly. The three legs

should have equal resistance +/- 5%. The resistance to ground should be 20

megohms or higher.

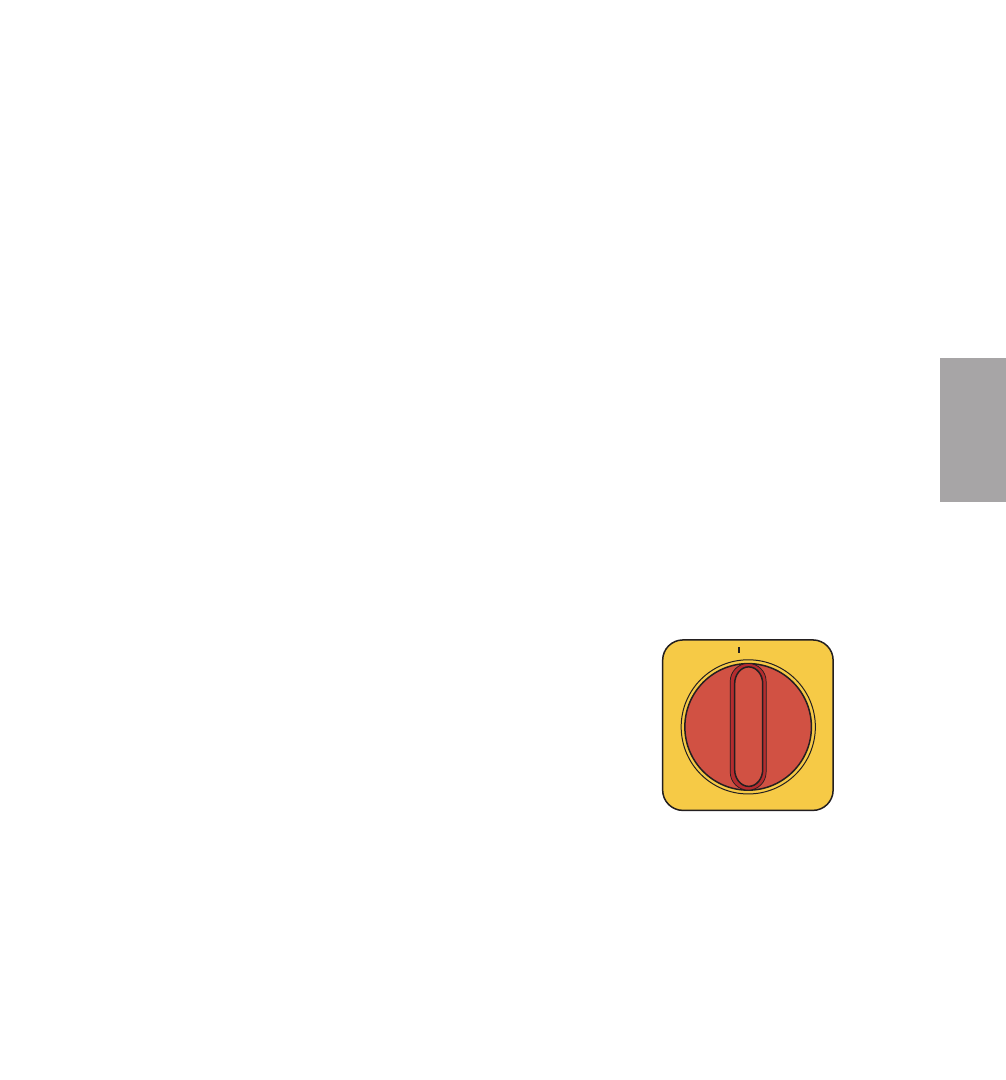

4 Turn on the main power to the HTC. Make sure the disconnect dial is in the

ON position. This powers up the control and the display lights will illuminate.

For Hot Air Dryer (HAD) Models Only

5

Bump (rapidly start and stop) the blower motor and verify the motor is

turning in the correct rotation according to the labels on the motor. If the

rotation is incorrect, shut off and lock out power and switch any two of the

three power legs on the line side of the disconnect provided with the blower.

6 Check the discharge damper setting. The handle on the outlet of the blower

is connected to the discharge damper. This is required to be set to the proper

position to deter

mine the pr

oper airflow for the heater/hopper. Adjust the dis-

charge damper until the blower pressure is 20 to 30 in. W.C.

(continued)

ON

O OFF

NOTE: See the blower specifi-

cations sheet in the appendix

for design supply pressure.

✐