7

Vermont Castings Madison

30001453

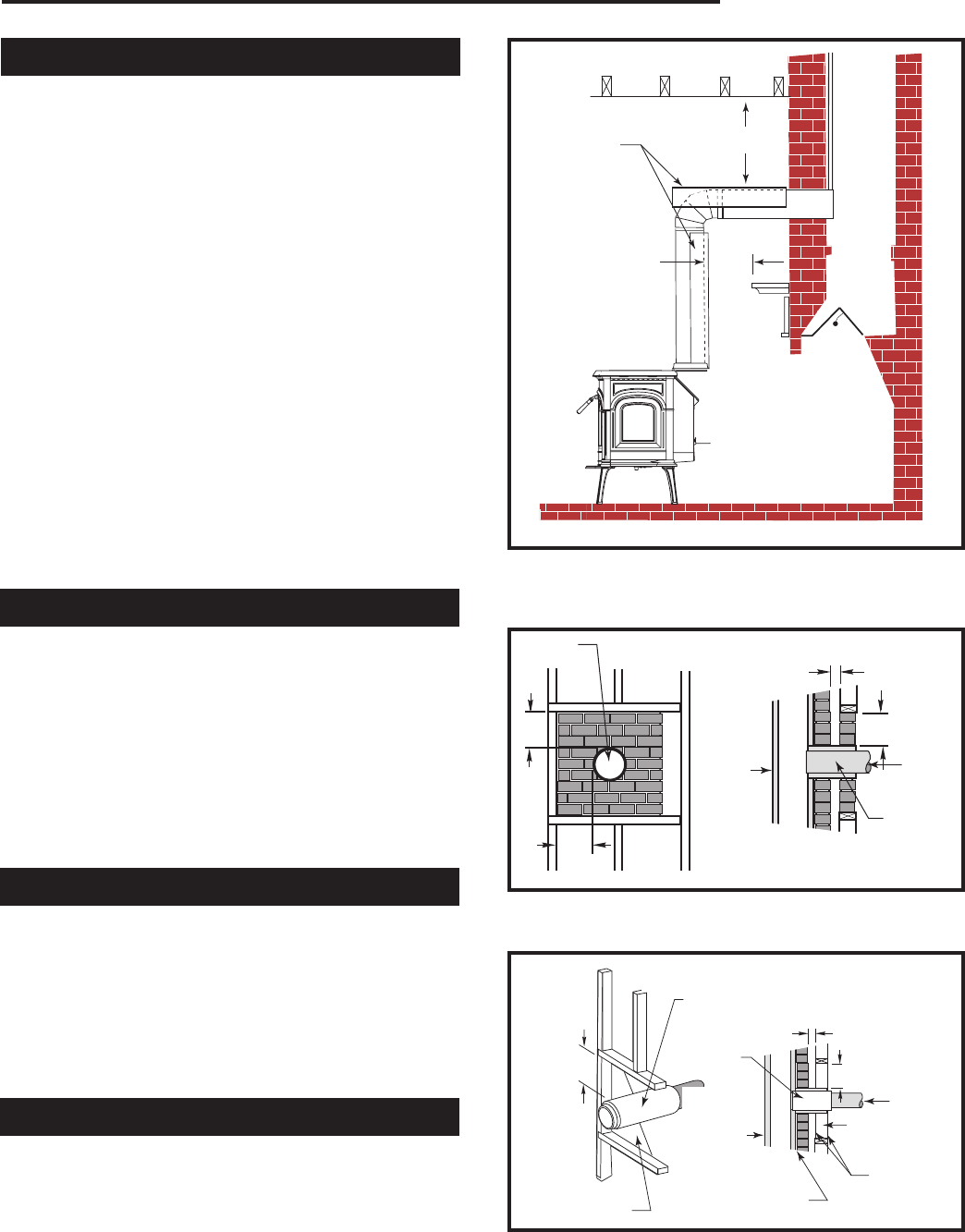

Connection Above the Fireplace

In this installation, the chimney connector enters the

fireplace flue through a thimble located above the

fireplace. (Fig. 6) The liner of the fireplace chimney

should extend at least to the point at which the chimney

connector enters the chimney. Follow all the guidelines

for installing a chimney connector into a freestanding

masonry chimney, and pay special attention to these

additional points:

• The stove and chimney connector clearances to

combustible mantel and trim materials are the same

as clearances to combustible walls. If necessary,

use a combination of mantel, trim, and connector

heat shields to provide the required clearances.

Refer to Page 12.

• Double-check connector clearance to the ceiling.

• The fireplace damper must be closed and sealed to

prevent room air from being drawn up the flue which

could reduce performance. However, it must be

possible to reopen the damper to inspect or clean

the chimney.

• Floor protection requirements also apply to fireplace

installations.

Wall Pass-throughs

Whenever possible, design the installation so that the

connector does not pass through a combustible wall.

If you must include a wall pass-through in your instal-

lation, check with your building inspector before you

begin. Also check with the chimney connector manu-

facturer for any specific requirements.

Consult with your dealer regarding special connection

components available for use as wall pass-throughs.

Use only parts that have been tested and listed for use

as a wall pass-through.

U.S. Requirements:

The National Fire Protection Association (NFPA) has

established guidelines for use in the United States for

passing chimney connectors through combustible walls.

Many building code inspectors follow these guidelines.

Figure 7 shows one NFPA-approved method. All com-

bustible material in the wall is cut away to provide 12”

(305mm) clearance to the connector. Brick and mortar

are used to enclose the clearance area.

Alternate methods approved by the NFPA:

• Using a section of double-wall chimney with a 9”

(229mm) clearance to combustibles. (Fig. 8)

• Placing a chimney connector pipe inside a steel

double-wall ventilated thimble, which is then sepa-

rated from combustibles by 6” (152mm) of fiberglass

insulating material. (Fig. 9)

ST272

masonry wall pass through

w/ single wall

connector

12/99

Min. 2” (51mm) Chimney clear-

ance to brick and combustibles

A = Minimum 12” (305 mm) brick con-

struction between liner and combustible

framing materials

Min. 12”

(305 mm)

Fire clay

liner

A

A

Chimney Flue

Fire clay

liner

Masonry

Chimney

constructed

to NFPA 211

Fig. 7 Masonry Wall Pass-through with single wall

chimney connector.

Chimney

connector

ST272

ST273

nfpa

factory built insulated

chimney section

12/99

Fig. 8 Wall Pass-through using factory-built insulated

chimney section.

Min. 9”

(230mm)

Air Space

Min. 9”

230mm

Chimney Flue

Sheet Steel

Supports

Min. 2”

(51mm)

Non-soluble refrac-

tory cement

Solid insulated,

listed factory-

built chimney

length set flush

with flue

Chimney

Connector

Masonry

Chimney

constructed to

NFPA 211

24 ga.Sheet

Steel Sup-

ports

ST273

ST244a

Madison

fplc over mantel

12/00

Fig. 6 If the clearance between the chimney connector and

either the ceiling or the mantel is inadequate, a protective

heat shield is required.

Note clearance

requirement on

pages 12-13

Mantel

Chimney Connector

Heat Shield

ST244a

*

*

*