29

3. Wire each terminal on the sensor to the same terminal on

the controller. See Fig. 15-25. Table 10 shows the recom-

mended Rnet wiring scheme.

Table 10 — Rnet Wiring

NOTE: The wire should be connected to the terminal shown.

Wiring a Supply Air Temperature (SAT) Sensor — The

SAT sensor is required for reheat applications.

If the cable used to wire the SAT sensor to the controller

will be less than 100 ft, an unshielded 22 AWG (American

Wire Gage) cable should be used. If the cable will be greater

than 100 ft, a shield 22 AWG cable should be used. The cable

should have a maximum length of 500 ft.

To wire the SAT sensor to the controller:

1. Wire the sensor to the controller. See Fig. 15-25.

2. Verify that the Enable SAT jumper is on.

3. Verify that the Enable SAT and Remote jumper is in the

left position.

Wiring an Indoor Air Quality (IAQ) Sensor

— An IAQ

sensor monitors CO

2

levels. The WSHP Open controller uses

this information to adjust the outside-air dampers to provide

proper ventilation. An IAQ sensor can be wall-mounted or

mounted in a return air duct. (Duct installation requires an aspi-

rator box assembly.)

The sensor has a range of 0 to 2000 ppm and a linear 4 to

20 mA output. This is converted to 1 to 5 vdc by a 250-ohm,

1

/

4

watt, 2% tolerance resistor connected across the zone con-

troller’s IAQ input terminals.

NOTE: Do not use a relative humidity sensor and CO

2

sensor

on the same zone controller if both sensors are powered off the

board. If sensors are externally powered, both sensors may be

used on the same zone controller.

If the cable used to wire the IAQ sensor to the controller

will be less than 100 ft, an unshielded 22 AWG (American

Wire Gage) cable should be used. If the cable will be greater

than 100 ft, a shield 22 AWG cable should be used. The cable

should have a maximum length of 500 ft.

To wire the IAQ sensor to the controller:

1. Wire the sensor to the controller. See Fig. 15-25.

2. Install a field-supplied 250-ohm,

1

/

4

watt, 2% tolerance

resistor across the controller’s RH/IAQ and Gnd

terminals.

3. Verify the the RH/IAQ jumper is set to 0 to 5 vdc.

Wiring a Relative Humidity (RH) Sensor

— The RH sensor

is used for zone humidity control (dehumidification) if the

WSHP unit has a dehumidification device. If not, the sensor

only monitors humidity.

NOTE: Do not use a relative humidity sensor and CO

2

sensor

on the same zone controller if both sensors are powered off the

board. If sensors are externally powered, both sensors may be

used on the same zone controller.

If the cable used to wire the RH sensor to the controller will

be less than 100 ft, an unshielded 22 AWG (American Wire

Gage) cable should be used. If the cable will be greater than

100 ft, a shield 22 AWG cable should be used. The cable

should have a maximum length of 500 ft.

To wire the RH sensor to the controller:

1. Strip the outer jacket from the cable for at least 4 in.

2. Strip

1

/

4

in. of insulation from each wire.

3. Wire the sensor to the controller.

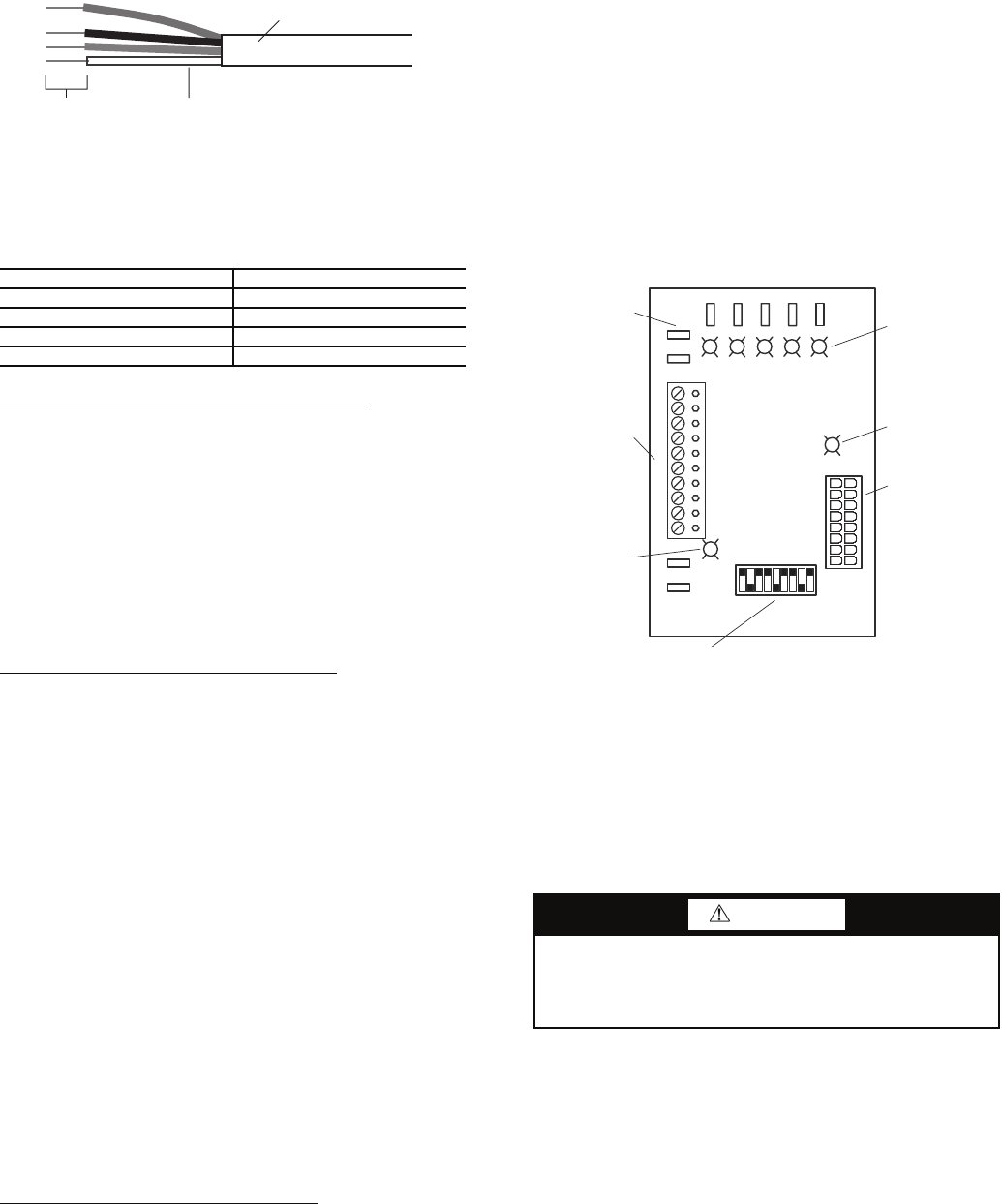

Step 10 — Operate ECM Interface Board —

The ECM fan is controlled by an interface board that converts

thermostat inputs and field selectable cfm settings to signals

used by the ECM (electronically commutated motor)

controller. See Fig. 33.

NOTE: Power must be off to the unit for at least three seconds

before the ECM will recognize a speed change. The motor will

recognize a change in the CFM Adjust or Dehumidification

mode settings while the unit is powered.

There are four different airflow settings from lowest airflow

rate (speed tap 1) to the highest airflow rate (speed tap 4).

Table 11 indicates settings for both versions of the ECM inter-

face board, followed by detailed information for each setting.

COOLING — The cooling setting determines the cooling

(normal) cfm for all units with ECM motor. Cooling (normal)

setting is used when the unit is not in Dehumidification mode.

Tap 1 is the lowest cfm setting, while tap 4 is the highest cfm

setting. To avoid air coil freeze-up, tap 1 may not be used if the

Dehumidification mode is selected. See Table 11.

HEATING — The heating setting determines the heating cfm

for 50PSH, PSV, PSD units. Tap 1 is the lowest cfm setting,

while tap 4 is the highest cfm setting. See Table 11.

CFM ADJUST — The CFM Adjust setting allows four selec-

tions. The NORM setting is the factory default position. The +

or – settings adjust the airflow by ±15%. The + or – settings are

used to “fine tune” airflow adjustments. The TEST setting runs

the ECM at 70% torque, which causes the motor to operate

like a standard PSC motor, and disables the cfm counter. See

Tables 11-13 for ECM and PSC blower motors performance

data.

WIRE TERMINAL

Red +12-v

Black .Rnet

White Rnet+

Green Gnd

–

CAUTION

When the disconnect switch is closed, high voltage is

present in some areas of the electrical panel. Exercise cau-

tion when working with energized equipment. Failure to

heed this safety precaution could lead to personal injury.

Fig. 32 — Rnet Cable Wire

OUTER JACKET

INNER INSULATION

.25 IN.

a50-8443

Y

GGGGR

W

O

Y2

Y1

G

R

C

Y2

Y1

G

O

W

C

R

DH

AL1

A

A

AL1

SW1

SW2

SW3

SW4

SW5

SW6

SW7

SW8

SW9

OFF

ON

G

DEHUM

CFM

TB1

J1

S1

THERMOSTAT

INPUT LEDS

CFM COUNTER

1 FLASH PER 100 CFM

ECM MOTOR

LOW VOLTAGE

CONNECTOR

1/4" SPADE

CONNECTIONS

TO COMPLETE C OR

DELUXE D BOARD

THERMOSTAT

CONNECTIONS

DEHUMIDIFICATION

LED

FAN SPEED SELECTION DIP SWITCH

Fig. 33 — ECM Interface Board Physical Layout

A50-7739