10

62--10458--00

BELT TENSION ADJUSTMENT -- Shut off unit power

supply. Loosen fan motor from mounting bracket. Do

not loosen motormounting bracket from unit. Movefan

motor up or down until proper belt t ension is achieved

(approximately 3/4--in. deflection with 8--pound

tension at midpoint of belt span).

Lubrication -- Fan motor and fan shaft bearings are

lubricated for the life of the bearings. No re--lubrication

is required

5.4 Return--Air Filter

Inspect filters twice monthly and clean as required by

operating conditions. Filter size and type are listed i n

Table 1, Table 3 or Table 2. To clean filters flush with

hot water or steam or soak in a mild water solution of

soap or detergent. Refer to filter manufacturer’s

instructions as applicable. Do not operate unit without

return--air filters in place.

5.5 Condensate Drain

Clean the drain line and unit drain pan at the start ofeach

coolingseason. Check flowby pouringwater intodrain.

Be sure trap is filled as shownin Figure 7to maintainan

air seal.

5.6 Evaporator Coil

WARNING

Never reach into unit while fan is running.

Lock open and tag unit disconnect before

working on fan. Remove fuses and take them

with you after noting this on tag.

Remove dirt and debris from evaporatorcoil as required

by condition. Clean coil with a stiff brush, vacuum

cleaner or compressed air. Use a fin comb of the correct

tooth spacing (Refer to

Table 1, Table 3 or Table 2 for

coil fins/inch) when straightening mashed or bent coil

fins.

5.7 W ater Regulating Valve

PREPARATION FOR OPERATION.

a. Openthe water regulating valve inlet and outletisola-

tion valves.

b. Close the water regulating valve bypass valve.

ADJUSTMENT

a.

The compressor discharge pressure is controlled by

the water regulating valve and may be monitored by

observing liquid line pressure.

NOTE

Adjustments to the water regulating valve must

be made slowly, allowing ample time for re-

sponse and stabilization.

b. Install a calibrated gauge at the liquid line service

port. Operatingliquid line rangefor R--22 units is 250

to 270 psig (1724 to 1862 kPa), for R--134a units is

155 to180 psig (1069 to 1241 kPa) andfor R-- 407C is

267 to 288 psig (1841 to 1986 kPa). If pressure read-

ing is below operating range, rotate t he square head

adjusting screw counterclockwise; this will increase

spring tension, decrease water flow and increasepres-

sure.

If pressure reading is above operating range, rotate

the square head adjusting screw clockwise; this will

decrease spring tension, increase water flow and de-

crease pressure.

c. Only the water regulating valve opening point is ad-

justable. The closing point is 3 to 7 psig below the

opening point and is non--adjustable.

5.8 Condenser

Condensers may require cleaning of water--deposited

scale.

WARNING

Follow all Safety codes. Wear safety glasses

and rubber gloves when using inhibited hy-

drochloric acid solution.

Clean condensers with an inhibited hydrochloric acid

solution. The acid can stain hands and clothing, attack

concrete and, without inhibitor, can attack steel. Cover

surroundings to guard against splashing. Vapors from

vent pipe are not harmful, but take care to prevent liquid

from being carried over by the gases.

Warm solution acts faster, but cold solution is just as

effective if applied for a longer period.

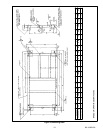

Figure 9 Gravity Flow Method

GRAVITY FLOW METHOD

a. Disconnect condenser piping at unit, including isola-

tion valves and water regulating valve.

b. Fill condenser as shown in Figure 9. Follow acid

manufacturer’s instructions. When condenser is full,

allow solution to remain overnight

c. Drain condenser and flush with clean water.

FORCED CIRCULATION METHOD

a. Disconnect condenser piping at unit, including isola-

tion valves and water regulating valve.

b. Fill system as shown in Figure 10. Follow acid

manufacturer’s instructions. Fully open vent pipe

when filling system. The vent may be closed when

system is full and pump is operating.