9

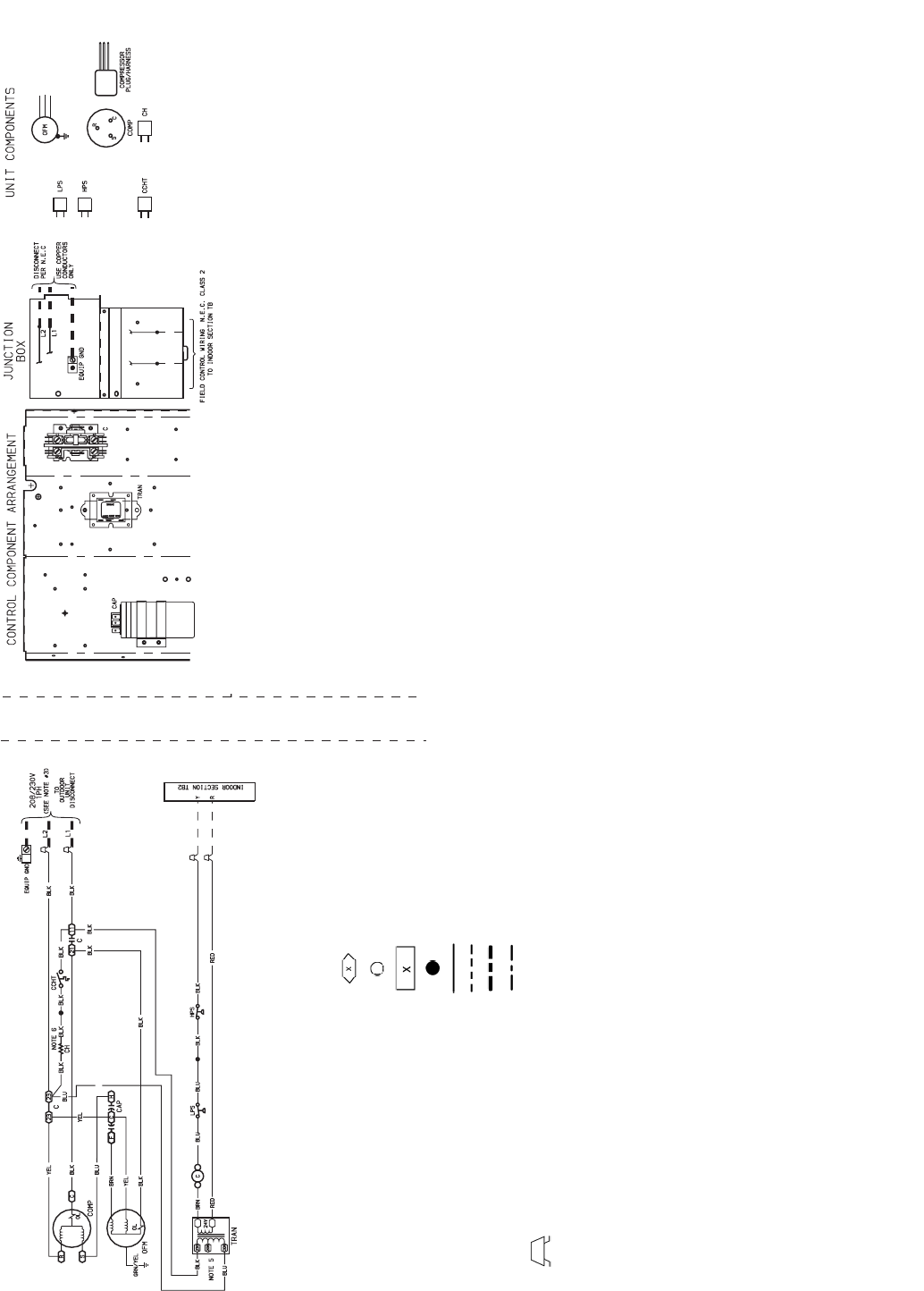

LEGEND

NOTES:

1. Compressor and fan motors are thermally protected.

2. Wire in accordance with National Electrical Code (NEC) and local codes. Replace

any original wires with 90° C wire or its equivalent.

3. Use minimum 60° C wire for field power wiring.

4. Transformer has internal 4.5A thermal fuse on the primary side.

5. Transformer factory wired for 230 v. For 208 v move black wire to 208 volt tap on

transformer.

6. Crankcase heater and thermostat used on selected models only.

C—Contactor, Compressor

CAP — Capacitor

CCHT — Crankcase Heater Thermostat

CH — Crankcase Heater

COMP — Compressor Motor

EQUIP— Equipment

GND — Ground

HPS — High-Pressure Switch

LPS — Low-Pressure Switch

OFM — Outdoor-Fan Motor

OL — Overload

TB — Terminal Board

TRAN — Transformer

Splice (Field)

Terminal (Marked)

Terminal (Unmarked)

Terminal Block

Splice

Factory Wiring

Field Control Wiring

Field Power Wiring

Optional or Accessory Wire

Fig. 6 — 38HDF018-036 Typical Wiring Schematic

38HDF OPERATION SEQUENCE

CALL FOR COOLING:

1. Control voltage from transformer to thermostat (24 v).

2. At thermostat 24 v is switched to “G” and “Y.”

3. 24 v from thermostat “G” energizes fan relay at indoor fan coil unit and indoor-fan motor runs.

4. 24 v from thermostat “Y” energizes the contactor coil and the compressor and outdoor-fan motor will both

run.

6. If the internal protection of the compressor or LPS or HPS open, the 24 v to contactor coil will be inter-

rupted. The compressor and outdoor-fan motor will stop.