10

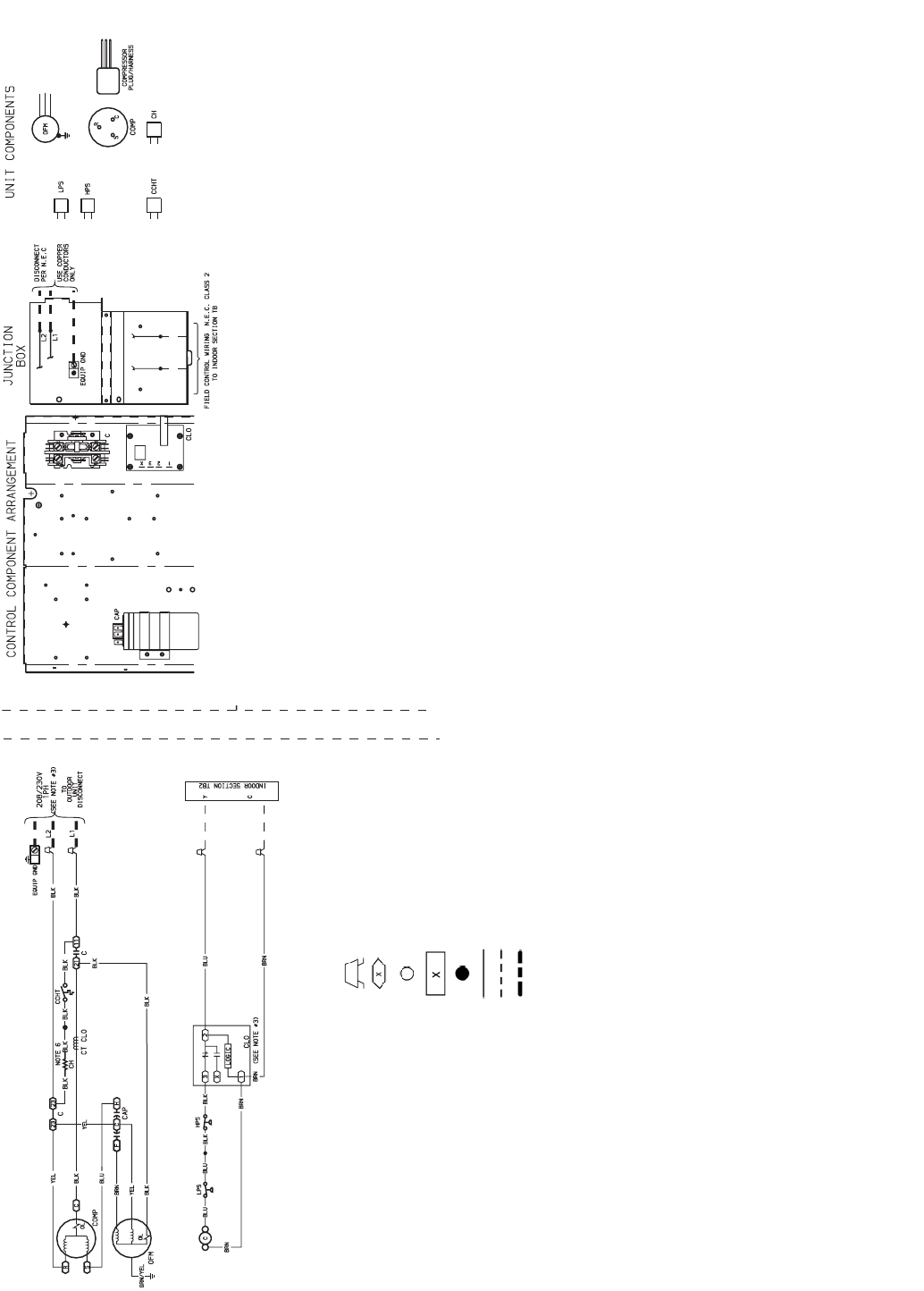

LEGEND

NOTES:

1. Compressor and fan motors are thermally protected.

2. Wire in accordance with National Electrical Code (NEC) and local codes. Replace

any original wires with 90° C wire or its equivalent.

3. The CLO locks out the COMP to prevent short cycling on COMP overloads and

safety devices. Before replacing CLO check these devices.

4. If indoor section has a transformer with a grounded secondary, connect the

grounded side to “C” on the low voltage board.

5. Use minimum 60° C wire for field power wiring.

6. Crankcase heater and thermostat used on selected models only.

C—Contactor, Compressor

CAP — Capacitor

CCHT — Crankcase Heater

Thermostat

CH — Crankcase Heater

CLO — Compressor Lockout

COMP — Compressor Motor

CT — Current Transformer

EQUIP — Equipment

GND — Ground

HPS — High-Pressure Switch

LPS — Low-Pressure Switch

OFM — Outdoor-Fan Motor

OL — Overload

TB — Terminal Board

Splice (Field)

Terminal (Marked)

Terminal (Unmarked)

Terminal Block

Splice

Factory Wiring

Field Control Wiring

Field Power Wiring

38HDR OPERATION SEQUENCE

CALL FOR COOLING:

1. Control voltage from transformer to thermostat (24 v).

2. At thermostat 24 v is switched to “G” and “Y.”

3. 24 v from thermostat “G” energizes fan relay at indoor fan coil and indoor-fan motor runs.

4. 24 v from thermostat “Y” energizes the logic in the CLO, and the contactor coil, both at the outdoor unit.

Compressor and outdoor-fan motor run.

6. If the internal protector of the compressor, HPS, or LPS open, the 24 v to the contactor coil will be inter-

rupted, the compressor and outdoor-fan motor will stop, and the CLO will keep the circuit open until reset

by stopping and restarting the 24 v power at the thermostat.

Fig. 7 — 38HDR018-060 Typical Wiring Schematic