7

Connect the Power Transformer —

An individual,

field-supplied, 24 vac power transformer is recommended for

each zone controller. If multiple zone controllers are powered

from one power transformer (100 va maximum for UL [Under-

writers’ Laboratories] Class 2 conformance), maintain polarity

on the power input terminals. All transformer secondaries are

required to be grounded. Use only stranded copper conductors

for all wiring to the zone controller. Wiring connections must

be made in accordance with NEC (National Electrical Code)

and local codes. Ground the transformer at the transformer lo-

cation. Provide an 18-gage, green, chassis ground wire at the

terminal.

The power supply is 24 vac ± 10% at 40 va (50/60 Hz).

For 33ZCVAVTRM zone controllers, the power require-

ment sizing allows for accessory water valves and for electric

heat contactor(s). Water valves are limited to 15 va on both

two-position and modulating hot water. The electric heat con-

tactor(s) are limited to 10 va (holding) each.

For 33ZCFANTRM zone controllers, the power require-

ment sizing allows for accessory water valves and for the fan

contactor. Water valves are limited to 8 va on both two-position

and modulating hot water. The fan contactor is limited to

11 va (holding).

NOTE: If a water valve or electric heat contactor exceeds

these limits, or external contactors are required for electric

heat, then it is recommended a 60 va transformer be used.

The maximum rating for any output is 20 va.

NOTE: Do not run sensor or communication wiring in the

same conduit with line-voltage wiring.

NOTE: An accessory conduit box (part no. 33ZCCONBOX) is

available for conduit wiring connections to the zone controller.

Perform the following steps to connect the power

transformer:

1. Install the field-supplied transformer in an electrical

enclosure that conforms to NEC and local codes.

2. Connect 24 vac from the transformer as shown in the

applicable wiring diagram (Fig. 8A-J).

Connect Airflow Pickups —

The zone controller de-

termines velocity pressure by obtaining the difference between

high and low duct pressure from two airflow pickups. The

pickups are connected to barb fittings on the zone controller

with

1

/

4

-in. polyethylene tubing. All piping for this purpose

must conform to local codes.

Figure 9 indicates the positions of the two barb fittings.

Perform the following steps to install and connect the air-

flow pickups:

1. Select a location on the air handler’s supply air duct

where the airflow pickups will be installed. The loca-

tion should be one where there are at least three duct

diameters of straight duct upstream of the pickups. If

this requirement is not met, stable airflow measure-

ments may not be possible.

2. Mount the field-supplied airflow pickup(s) in the duct,

following the manufacturer's directions. Two individ-

ual pickups may be used, one for high pressure airflow

and one for low pressure airflow. A dual pickup, which

combines the two functions, may also be used. When

using individual pickups, make sure that the one for

high pressure airflow faces upstream, in the direction

the air is coming from, and the one for low pressure

airflow faces downstream, in the direction the air is

going to.

3. Use field-supplied

1

/

4

-in. tubing (rated for the applica-

tion) to connect the high pressure airflow pickup to

barb fitting P1 on the pressure transducer. At the zone

controller, the P1 fitting is on the side with the filter

installed. Be careful to avoid sharp bends in the tubing,

because malfunctions may occur if the tubing is bent

too sharply. Use at least 2 ft of tubing for reading

stability.

4. Use field-supplied

1

/

4

-in. tubing (rated for the applica-

tion) to connect the low pressure airflow pickup to

barb fitting P2 on the pressure transducer. Be careful to

avoid sharp bends in the tubing, because malfunctions

may occur if the tubing is bent too sharply. Use at least

2 feet of tubing for stability.

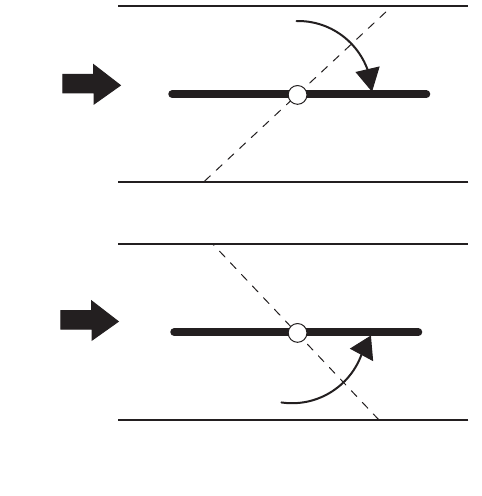

AIR

FLOW

AIR

FLOW

CW TO OPEN, CCW TO CLOSE

CCW TO OPEN, CW TO CLOSE

Fig. 7 — Damper Configuration