85

3. Inspect the wiring to verify the conductors are in

good condition and attached securely.

CAUTION

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation. Verify

proper operation after servicing.

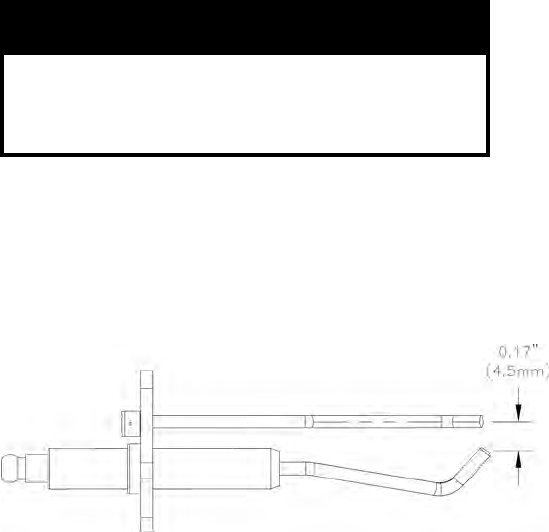

4. Remove the ignition electrode and inspect it for

oxides. Clean the oxides from the electrode with

steel wool. Do not use sandpaper for the cleaning.

Inspect the ceramic insulator for cracks and replace

the ignitor assembly if necessary. Check the ignitor

electrode spacing gap. Refer to Figure 56 “Ignitor

Electrode Gap” for details.

10.

Reinstall the burner, burner hood and fan/gas valve

assembly.

1

1. Reconnect any wiring which has been disconnected.

12. Inspect the heating system and correct any other

deciencies prior to restarting the boiler.

13. Follow Section XI System Start-up before leaving

installation.

14. Perform the combustion test outlined in Section XI

System Start-up.

15. Verify that the system PH is between 8.2 and 9.5/.

16. Check for vent terminal obstructions and clean as

necessary.

D. Recommended Heating System Water Treatment

Products:

1. System Cleaning and Conditioning:

a. The following heating system water treatment

products are recommended for an initial existing

heating system sludge removal, initial boiler

cleaning from copper dust, ux residue and any

boiler debris and for preventive treatment as

corrosion/scale inhibitors:

i. Fernox™ Restorer (universal cleaner, sludge

remover, scale remover, ux residue/debris

remover, corrosion inhibitor)

ii. Fernox™ Protector (Alphi 11, CH#, Copal)

(sludge remover, corrosion inhibitor)

Follow manufacturer application procedure

for proper heating system/boiler cleaning

and preventive treatment.

Above referenced products are available

from Cookson Electronics Company, 4100

Sixth Avenue, Altoona, PA 16602, Tel:

(814) 946-1611 and/or selected HVAC

distributors. Contact US Boiler for specic

details.

iii. Equivalent system water treatment products

may be used in lieu of products referenced

above.

2. System Freeze Protection:

a. The following heating system freeze protection

products are recommended for Alpine boilers:

i. Fernox™ Protector Alphi 11 (combined

antifreeze and inhibitor).

Follow manufacturer application procedure

to insure proper antifreeze concentration and

inhibitor level.

Above referenced product is available from

Cookson Electronics Company, 4100 Sixth

Avenue, Altoona, PA 16602, Tel: (814) 946-

1611 and/or selected HVAC distributors.

Contact US Boiler for specic details.

Figure 56: Ignitor Electrode Gap

5. Remove the fan/gas valve assembly from the burner

hood. Inspect for lint and dust. If signicant lint

and dust are found, disassemble the fan/gas valve

assembly to expose the swirlplate and fan inlet (see

the exploded diagram in the parts list at the back of

this manual). Vacuum these parts as required, being

careful not to damage the vanes on the swirlplate.

6.

Remove the burner hood to access the burner and

the combustion chamber.

7. Remove the burner and vacuum any dust or lint

from the burner. If the burner shows signs of

deterioration or corrosion, replace it immediately.

Inspect the burner gasket and replace, if necessary.

8. Inspect the heat exchanger, clean and vacuum any

debris found on the surfaces. A soft nylon brush

must be used for cleaning. Remove insulation disc

and clean the surfaces by ushing with clean water.

Drain and ush the inside of the heat exchanger

and condensate collector. Do not use any cleaning

agents or solvents. Re-install insulation disc.

9. Inspect the condensate trap to verify it is open and

free from debris. Inspect condensate line integrity

between boiler and condensate neutralizer (if used)

and condensate neutralizer and the drain. Clean/

repair if needed.

If the condensate neutralizer is used, check pH

before and after the neutralizer to determine

neutralizing effectiveness. Replace limestone chips

and clean out the neutralizer if needed.