25

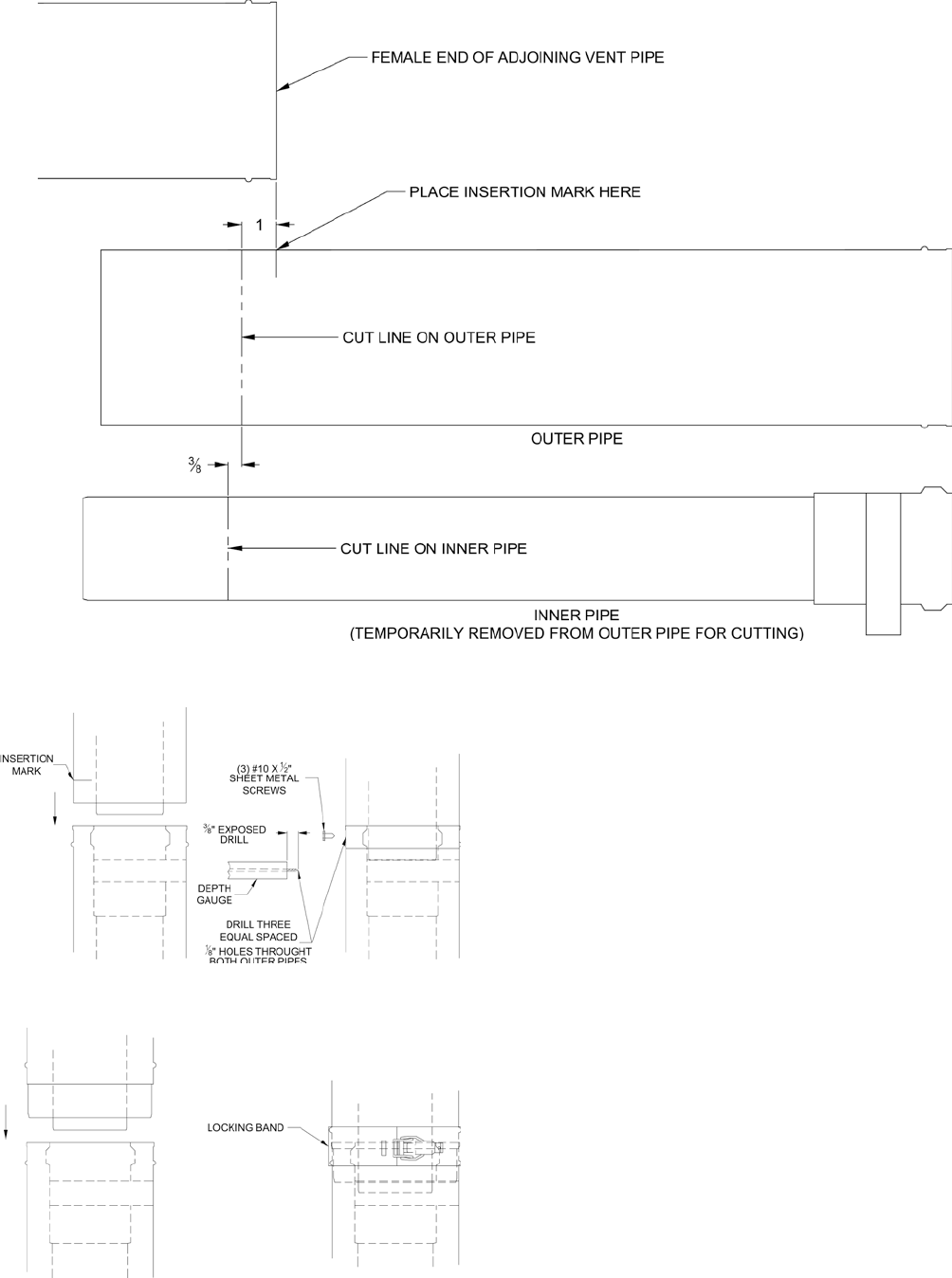

Figure 22: Cutting Straight Pipe

Figure 23: Joining Cuttable Pipe

Figure 24: Joining Non-Cuttable Pipe

b. Push the male end of the rst tting into the

boiler collar until it bottoms out. The male end

of cuttable sections should go 1” into the collar

until the insertion mark (made in Step 2d above)

is covered. On other ttings, the bead on the

male pipe will be bottom out on the collar (see

Figure 24).

c.

The male end of cuttable ttings must be held to

the collar with three (3) #10 x 1/2” sheet metal

screws. Drill a 1/8 hole through both outer pipes

to start this screw. Use a drill stop or other

means to ensure that the drill bit does not

penetrate more than 3/8” into the outer pipe.

Do not use a sheet metal screw longer than

1/2” (see Figure 23).

d. Use locking bands (provided with all ttings) to

secure non-cuttable pipe, as well as ttings, to

the boiler collar (see Figure 24).

e. Use the same method to join all remaining vent

components except for the terminal.

Vertical (Roof Terminal Installation

1. Vertical (Roof) Terminal Installation. Refer to

Figures 26, 27 and 28.

In addition to the vertical terminal, either a Flat

Roof Flashing or Sloped Roof Flashing is required

for this installation. Refer to Table 8 ‘Concentric

Vent Components’ for details.