12

Vent Pipe Pipe Direction Enclosure

Minimum Clearance To

Combustible Material, Inches

CPVC/PVC Venting Vertical or Horizontal Enclosed at all Sides 1” Vent/0” Combustion Air

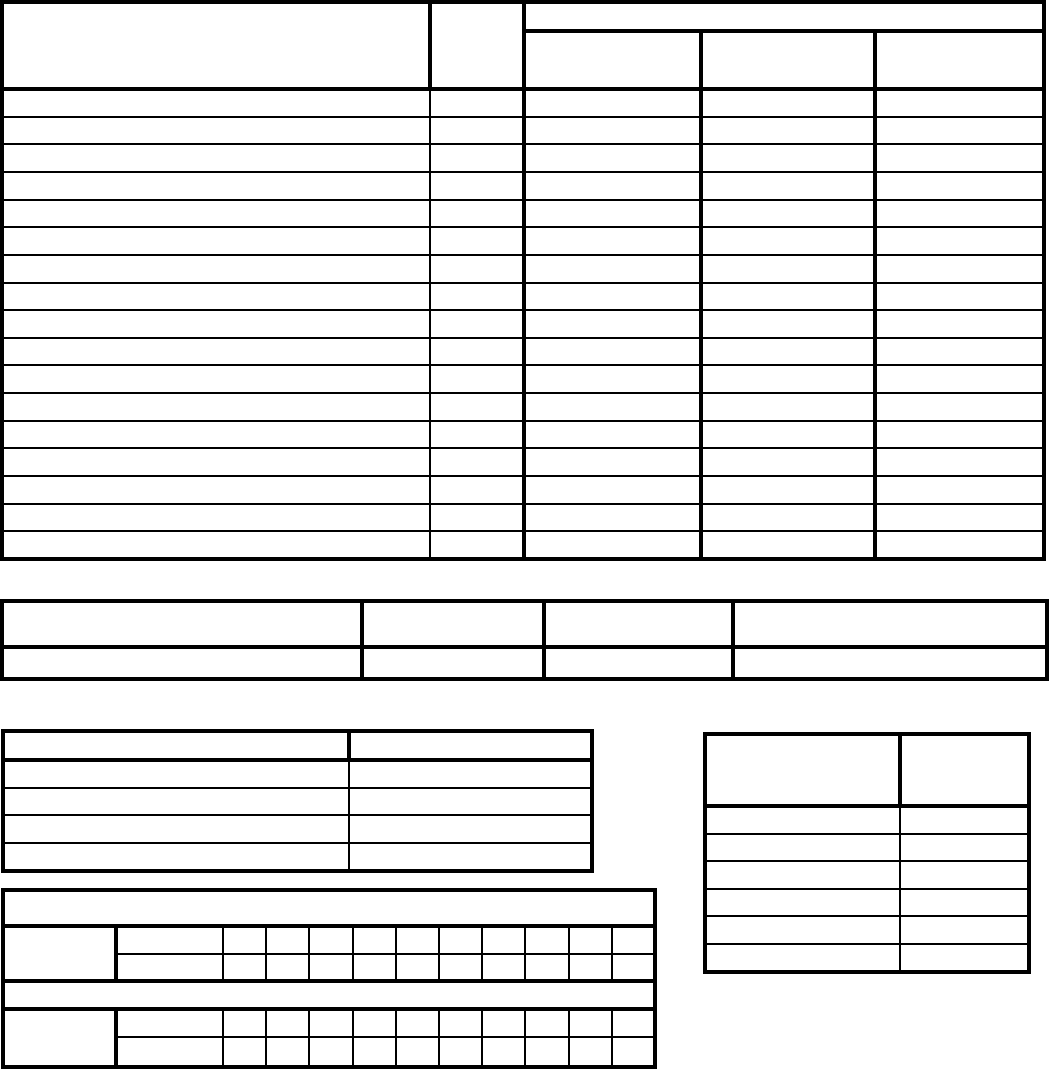

Table 5: Clearances from Vent Piping to Combustible Material

Vent System Components

Part

Number

Quantity

ALP080 & ALP105

(P/N 102189-01)

ALP150 & ALP210

(P/N 102189-02)

ALP285 & ALP399

(P/N 102189-03)

3” Schedule 40 PVC Tee Combustion Air/Vent Terminal 102190-01 2 1 ---

4” Schedule 40 PVC Tee Combustion Air/Vent Terminal 102190-02 --- 1 2

3” Stainless Steel Rodent Screens 102191-01 2 1 ---

4” Stainless Steel Rodent Screens 102191-02 --- 1 2

3” x 30” Schedule 40 CPVC Pipe 102193-01 1 1 ---

4” x 30” Schedule 40 CPVC Pipe 102193-02 --- --- 1

3” Schedule 80 CPVC 90° Elbow 102192-01 1 1 ---

4” Schedule 80 CPVC 90° Elbow 102192-02 --- --- 1

8 oz. Bottle of Transition Cement 102195-01 1 1 1

8 oz. Bottle of Primer 102194-01 1 1 1

Burnham Vent Supplement Manual 102188-01 1 1 1

Two Pipe Vent System Connector for CPVC/PVC 102183-01 1 --- ---

Two Pipe Vent System Connector for CPVC/PVC 102183-02 --- 1 ---

Two Pipe Vent System Connector for CPVC/PVC 102183-03 --- --- 1

Two Pipe Vent System Connector for CPVC/PVC Gasket 102185-01 1 1 ---

Two Pipe Vent System Connector for CPVC/PVC Gasket 102185-02 --- --- 1

Silicone Vent Sensor Cap 102153-01 1 1 1

Table 4: Vent System Components Included with Boiler

Table 6: Burnham Vent System and Combustion Air System Components

Vent System Component Equivalent Length (Ft.)

3” Schedule 40 CPVC Pipe x 30 Inches 2.5

4” Schedule 40 CPVC Pipe x 30 Inches 2.5

3” Schedule 80 CPVC 90° Elbow 5

4” Schedule 80 CPVC 90° Elbow 5

Combustion Air

System Component

(Parts by Others)

Equivalent

Feet of Pipe*

3” or 4” ID Pipe x 1 Ft. 1

3” or 4” ID Pipe x 2 Ft. 2

3” or 4” ID Pipe x 4 Ft. 4

3” or 4” ID Pipe x 5 Ft. 5

3” or 4” 90° Elbow 5

3” or 4” 45° Elbow 5

*Equivalent Feet of Pipe Based on

Standard 4” PVC Design

Maximum Number of 90’s and Straight Pipe

Vent Pipe

# of 90’s 1 2 3 4 5 6 7 8 9 10

Feet of Pipe 55 50 45 40 35 30 25 20 15 10

Combustion

Air Pipe

# of 90’s 1 2 3 4 5 6 7 8 9 10

Feet of Pipe 55 50 45 40 35 30 25 20 15 10

to public walkway. Do not install over public

walkway where local experience indicates

appliance ue gas vapor or condensate creates a

nuisance or hazard.

b. Minimum three (3) feet above any forced

combustion air located within ten (10) feet.

c. Direct Vent - Minimum one (1) foot below, one

(1) foot horizontally from, or one (1) foot above

any door, window, or gravity air inlet.

d. Minimum four (4) feet horizontally from electric

meters, gas meters, regulators, and relief valves.

This distance may be reduced if equipment is

protected from damage due to condensation or

vapor by enclosure, overhangs, etc.

e. Minimum twelve (12) inches from overhang or

corner of building.

6. Enclose vent passing through occupied or

unoccupied spaces above the boiler with material

having a re resistance rating of at least equal to the

rating of the adjoining oor or ceiling. Maintain

minimum clearances to combustible materials. See

Figure 2 and Table 5 for details.