19

5. Install maximum vertical run of seven (7) feet of

Schedule 40 PVC vent pipe. See Figure 11.

6. At top of vent pipe length install another PVC 90°

elbow so that elbow leg is opposite the building’s

exterior surface.

7. Install Rodent Screen and Combustion Air Terminal

(supplied with boiler), see Figure 8 for appropriate

conguration.

8. Brace exterior piping if required.

H. The following information is applicable for

Combination Concentric Gas Vent/Combustion air

System (optional).

I. Field Installation of Boiler Concentric Vent Collar

The Boiler Concentric Vent Collar is shipped inside the

boiler in plastic bag. The Collar mounting hardware

- six (6) #8 x ½” black oxide round head Phillips sheet

metal screws - are shipped inside Miscellaneous Part

Carton.

1.

Release four side draw latches and remove boiler

lower front door assembly to gain access to the Vent

Collar.

2.

Remove the collar from the bag and set aside.

3. Locate and remove six mounting screws.

4. Position the Collar onto jacket combination rear/

bottom panel and insert collar inner stainless steel

vent pipe into the heat exchanger vent outlet.

5.

Align collar plate clearance holes with rear/bottom

panel engagement holes; then secure the collar to

rear/bottom panel with six mounting screws. See

Figure 12.

6. Flue temperature sensor, factory attached to the

boiler wiring harness, is secured to the boiler rear/

bottom panel with tape.

7. Remove the tape and push the sensor rubber plug

into Concentric Vent Collar sensor port until the

plug is securely engaged. See Figure 12.

The installation of the Concentric Vent Collar is now

completed.

J. General Guidelines - Concentric Venting

1. Vent system installation must be in accordance

with National Fuel Gas Code, NFPA 54/ANSI

Z221.3 or applicable provisions of local building

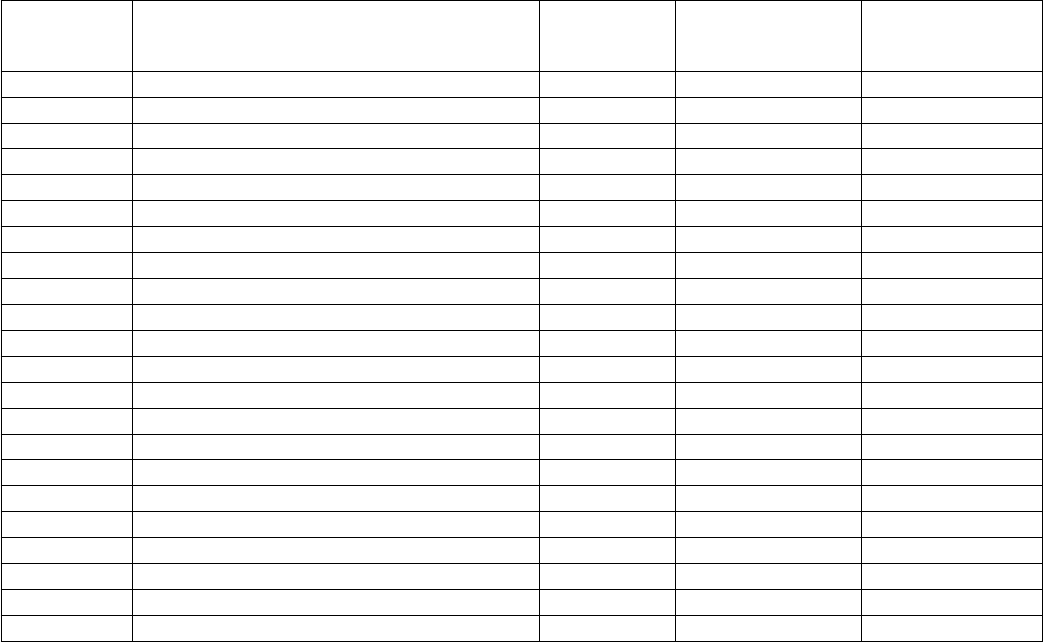

Table 8: Concentric Vent Components

Part Number Component Description Size

Component

Equivalent Vent

Length, Ft

Comments

101493-01 90° Elbow – Long Radius 80/125 mm 5.5

101491-01 45° Elbow - Long Radius 80/125 mm 3.0

101163-01 Cut -To-Length Extension, 500 mm (19-1/2”) 80/125 mm 1.63 **Can be cut

101162-01 Cut -To-Length Extension, 1000 mm (39”) 80/125 mm 3.25 **Can be cut

101485-01 Fixed Extension, 2000 mm (78”) 80/125 mm 3.25 ***Must not be cut

101808-01 Horizontal (Wall) Terminal 80/125 mm *NA Supplied with boiler

101495-01 Vertical Roof Terminal 80/125 mm *NA See Note 1

101496-01 Flat Roof Flashing 80/125 mm

101497-01 Sloped Roof Flashing 80/125 mm See Note 2

101492-01 Support Elbow with Chimney Chase Bracket 80/125 mm 8.5 See Note 3

101498-01 Hanger Wall Bracket 80/125 mm

101548-01 90° Elbow – Long Radius 100/150 mm 8.0

101549-01 45° Elbow - Long Radius 100/150 mm 3.0

101550-01 1 Cut -To-Length Extension, 500 mm (19-1/2”) 100/150 mm 1.63 ** Can be cut

101551-01 Cut -To-Length Extension, 1000 mm (39”) 100/150 mm 3.25 ** Can be cut

101553-01 Fixed Extension, 2000 mm (78”) 100/150 mm 6.5 *** Must not be cut

101809-01 Horizontal (Wall) Terminal 100/150 mm * NA Supplied with boiler

101557-01 Vertical (Roof) Terminal 100/150 mm * NA See Note 1

101558-01 Flat Roof Flashing 100/150 mm

101559-01 Sloped Roof Flashing 100/150 mm See Note 2

101560-01 Support Elbow with Chimney Chase Bracket 100/150 mm 10.0 See Note 3

101561-01 Hanger Wall Bracket 100/150 mm

N

otes:

* NA – do not include vent terminal into total vent length calculations.

** These sections have plain male end and beaded female end. See Figure 11 for details.

*** These sections have beaded male end and beaded female end. See Figure 12 for details.

1. Vertical terminal can be used with either of the roof ashings listed beneath it.

2. Sloped roof ashing suitable for roof angles between 25° and 45°.

3. Used at base of vertical run inside unused masonry chimney.