24

After approximately 60 seconds without

any key pressed, the display will enter a

dim display mode. To return to the bright

display mode, simply press any key.

2. Control Operating Characteristics

The L7248/L7224 can be in any three (3)

operational states: Normal, High-Limit and Error.

The controller moves back and forth from High-

Limit to Normal state as part of normal operation.

The controller will enter the Error state when there

is an abnormal condition. The operating states are:

a. Normal: Boiler temperature has gone below the

high limit setting (minus the differential) and has

not exceeded the high limit setting.

b. High-Limit: Boiler temperature has gone above

the high limit setting and has not dropped below

the high limit setting (minus the differential).

c. Error: The controller has detected an error

condition (e.g., open sensor) and has shut down

the burner output. The controller continues to

monitor the system and automatically restarts if

the error condition clears. See Table 4.

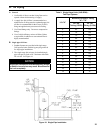

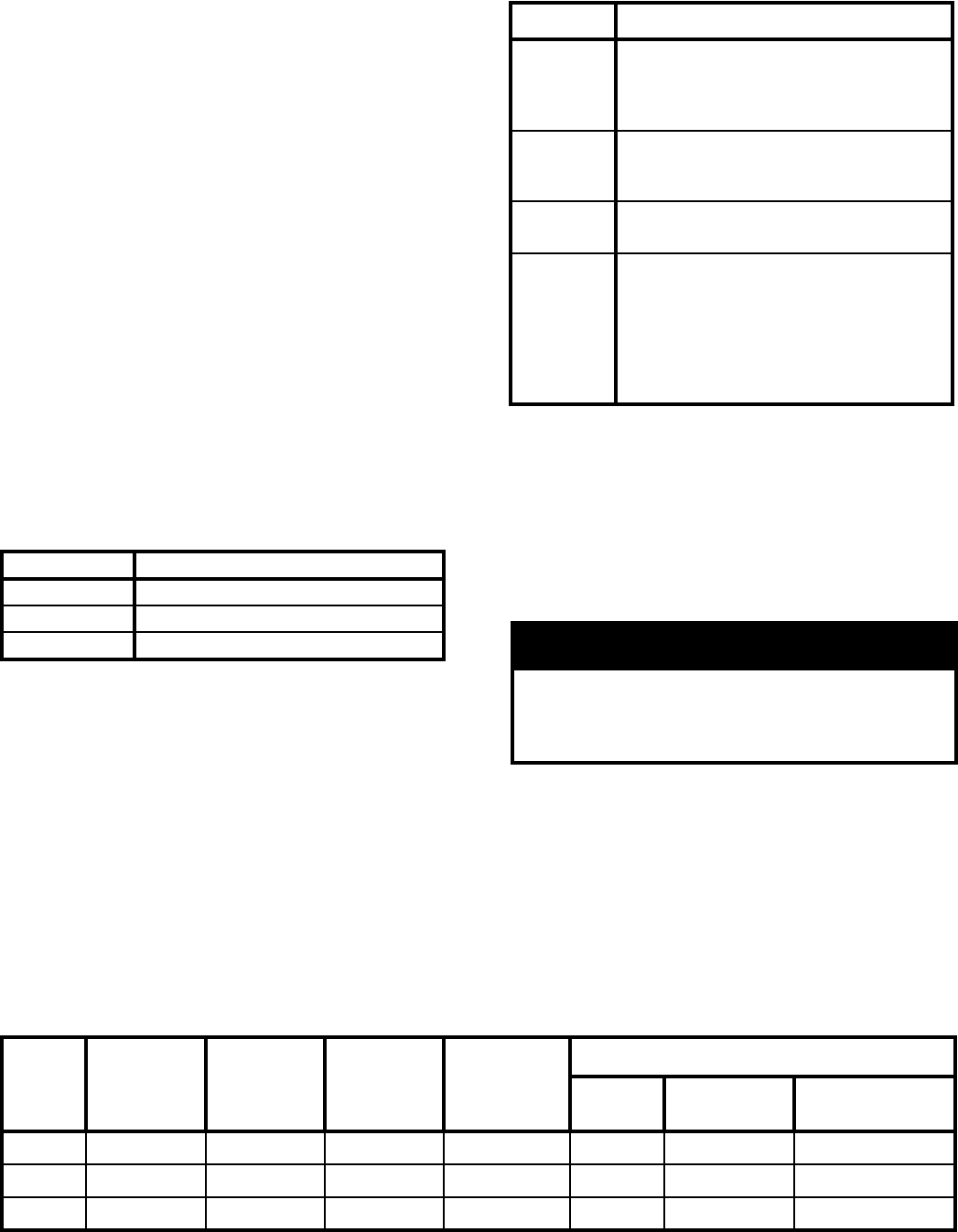

Table 4: LED Error Codes

Error Code Cause/Action

Err1 Sensor fault; check sensor.

Err2 ECOM fault; check EnviraCom™ wiring.

Err3 Hardware fault’ replace control.

d. Low-Limit: Boiler temperature has gone

below the low limit setting (minus the low limit

differential) and has not gone above the low limit

setting.

e. The operating sequence for L7248/L7224 is

described below and shown in Table 5.

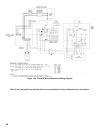

The switching action in the L7248/L7224 control

has one setting, the high limit, see Figure 14.

The switching relay is controlled by the low

voltage room thermostat. On a call for heat, the

relay contacts make to complete the line voltage

circulator circuit and also the burner circuit if the

boiler water temperature is below the high limit

Table 5: L7248/L7224 Controller

Operating Sequence

noitcA esnopseRmetsyS

tatsomrehT

rofsllac

taeh

.stratsrotalucriC

renruB.dekcehcsierutarepmetrelioB

sierutarepmetretawehtnehwstratser

.gnittestimilhgihwoleb

relioB

ehtsdeecxe

timilhgih

nehwstratserrenruB.ffodenrutsirenruB

ehtwolebsporderutarepmetretaweht

.laitnereffidehtsunimgnittestimilhgih

tatsomrehT

deifsitassi

.ffonrutrenrubdnarotalucriC

rorrE

noitidnoc

stuptuolla,detcetedsinoitidnocrorrenafI

lortnoC.ffosirenruB.nwodtuhsera

nehwstratserdnanoitcnufotseunitnoc

.detcerrocsirorre

eht,ecneuqeskcehcrorreehtgniruD

dnarosnesehtnitfirdrofskcehcmetsys

.snoitcennocehtninoisorroc

setting. The high limit switch shuts off the burner

if boiler water temperature exceeds the high limit

setting. The circulator will continue to operate

as long as the thermostat is calling for heat. The

high limit automatically resets after the water

temperature drops past the setpoint and through

the differential.

F. BURNER START-UP

WARNING

Do not attempt to start the burner when excess

oil has accumulated in the chamber, when boiler

is full of vapor or when combustion chamber is

very hot.

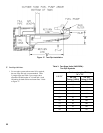

1. VERIFY burner settings.

a. Refer to Table 6 for Beckett Burner Settings.

Refer to Table 6A for Riello BF Burner Settings.

b. Check electrodes to comply with dimensions

shown in Figure 20A. For adjustment, loosen the

electrode clamp screw and slide/rotate electrodes

as needed. Securely re-tighten the clamp screw

when nished.

Boiler

Model

Firing Rate

(GPH)

Burner

Model

Air Tube

Combination

Delavan

Nozzle

Settings

Air

Head

(stop screw)

Pump Pressure

(PSIG)

LEDV1 0.60 AFII 85 HLX50HD 0.50 x 70°B 2.5 #2 140

LEDV2 1.00 AFII 150 HLX50HE 0.85 x 60°B 3.5 #3 140

LEDV3 1.25 AFII 150 HLX50HE 1.00 x 60°B 4.0 #5 140

Table 6: Beckett AFII Burner