16

e. Secure the inside trim plate to inside wall.

f. Tighten the gear clamp to the terminal pipe.

g. Seal all external joints with a weatherproof

caulk.

2. Cut vent pipe to length with a hack saw.

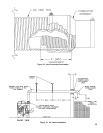

3. Install Vent Connector/Appliance Adaptor. See

Figures 11 and 12.

a. Apply a continuous bead of high temperature

adhesive/sealant (supplied with boiler) around

outside of corrugated pipe of vent connector.

b. Twist vent connector into end of vent pipe.

Turn the connector counter-clockwise until it is

engaged approximately 4 inches into the inner

vent pipe and the outer collar of the connector

overlaps the outside of the vent pipe.

c. Tighten the gear clamp on the outer collar of the

connector.

d. Repeat steps a. through c. with the appliance

adapter.

4. Connect vent pipe to boiler.

a. Apply a continuous bead of high temperature

adhesive/sealant (supplied with boiler) to inside

of appliance adapter (approximately ½ inch from

end).

b. Slip appliance adapter over boiler ue collar and

tighten gear clamp.

5. Connect vent pipe to terminal.

a. Carefully slide insulation sleeve over vent

connector and vent pipe until gear clamp on

small end of connector can be accessed.

WARNING

Do not operate LEDV with barometric damper in

vent. Do not connect venting to chimney.

b. Apply a continuous bead of high temperature

adhesive/sealant (supplied with boiler) on inside

of cent connector (approximately ½ inch from

end).

c. Clip connector over vent terminal until it is fully

engaged. Then tighten gear clamp.

d. Slide insulation sleeve over terminal connection

so that connector is completely covered.

e. Secure each end of insulation sleeve with the

gear clamps provided.

6. Secure vent pipe in position with pipe straps.

a. All horizontal runs must rise at least ¼ inch per

foot toward vent terminal.

b. Avoid any sags or dips in vent pipe.

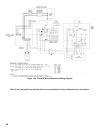

C. Air Intake Installation (Direct Vent only)

See Figure 13.

WARNING

Do not reduce size of air intake pipe.

Read, understand and follow combustion air

instruction restrictions contained in the Pre-

Installation Section of this manual.

1. General

a. Use 4 inch diameter single wall metal pipe and

ttings available at most heating distributors.

Maximum allowable air intake length is 40

equivalent feet. Each elbow is equal to 6

equivalent feet.

b. Start at Burner. Work toward air intake terminal.

c. Maintain minimum of ¼ inch per foot slope in

horizontal run to air intake terminal. Slope down

toward air intake terminal.

d. Seal all joints gas-tight, using silicone caulk or

self-adhesive aluminum tape.

2. After determining location, cut a hole in the wall to

accept 4 inch air intake pipe.

3. Remove the black plastic inlet cover from the right

side of the Beckett AFII burner.

4. Mount the vacuum relief valve tee assembly or 90°

elbow into the burner inlet ring. See Figure 13.

a. Secure with at least three (3) sheet metal screws

evenly spaced around the burner inlet ring.

b. Assemble the vacuum relief valve balance

weight onto the gate. Refer to the vacuum relief

valve manufacturer's instructions.

c. Mount the vacuum relief valve into the tee and

fasten with a screw and nut in collar tabs. To

ensure proper operation, the gate must be level

across the pivot point and plumb. Refer to

vacuum relief valve manufacturer's instructions.

5. Install remainder of air intake, securing each joint

with at least three (3) sheet metal screws evenly

spaced.

WARNING

Do not locate air intake termination where natural

convention or wind conditions may cause the

boiler exhaust gases to be drawn into the air

intake.