IV. FIELD CONNECTIONS

A. External Trap Condensate Drain

The unit’s

3

⁄

4

-in. condensate drain connections are located

on the bottom and side of the unit. Unit discharge connec-

tions do not determine the use of drain connections; either

drain connection can be used with vertical or horizontal

applications.

When using the standard side drain connection, make sure

the plug in the alternate bottom connection is tight before in-

stalling the unit.

To use the bottom drain connection for a roof curb installa-

tion, relocate the factory-installed plug from the bottom con-

nection to the side connection. See Fig. 7. The piping for the

condensate drain and external trap can be completed after

the unit is in place.

All units must have an external trap for condensate drain-

age. Install a trap at least 4-in. deep and protect against freeze-

up. See Fig. 8. If drain line is installed downstream from the

external trap, pitch the line away from the unit at 1 in. per

10 ft of run. Do not use a pipe size smaller than the unit

connection.

B. Field Duct Connections

NOTE: The design and installation of the duct system must

be in accordance with NFPA standards for the installation of

nonresidence-type air conditioning and ventilating systems,

NFPA No. 90A or residence-type, NFPA No. 90B, and/or local

codes and ordinances.

Adhere to the following criteria when selecting, sizing and

installing the duct system:

1. Remove appropriate panels from unit to obtain either

horizontal or vertical discharge. If units are installed in

horizontal discharge applications, remove vertical dis-

charge duct covers, save screws and install covers over

vertical duct openings.

2. Select and size ductwork, supply-air registers and return-

air grilles according to ASHRAE (American Society of

Heating, Refrigeration and Air-Conditioning Engi-

neers) recommendations.

CAUTION:

When drilling the duct system fastening

holes into the side of the unit for duct flanges, be care-

ful not to puncture the coil or coil tubes. See Fig. 9.

MAXIMUM ALLOWABLE DIFFERENCE (in.)

A-B B-C A-C

0.5 1.0 1.0

Fig. 5 — Unit Leveling Tolerances

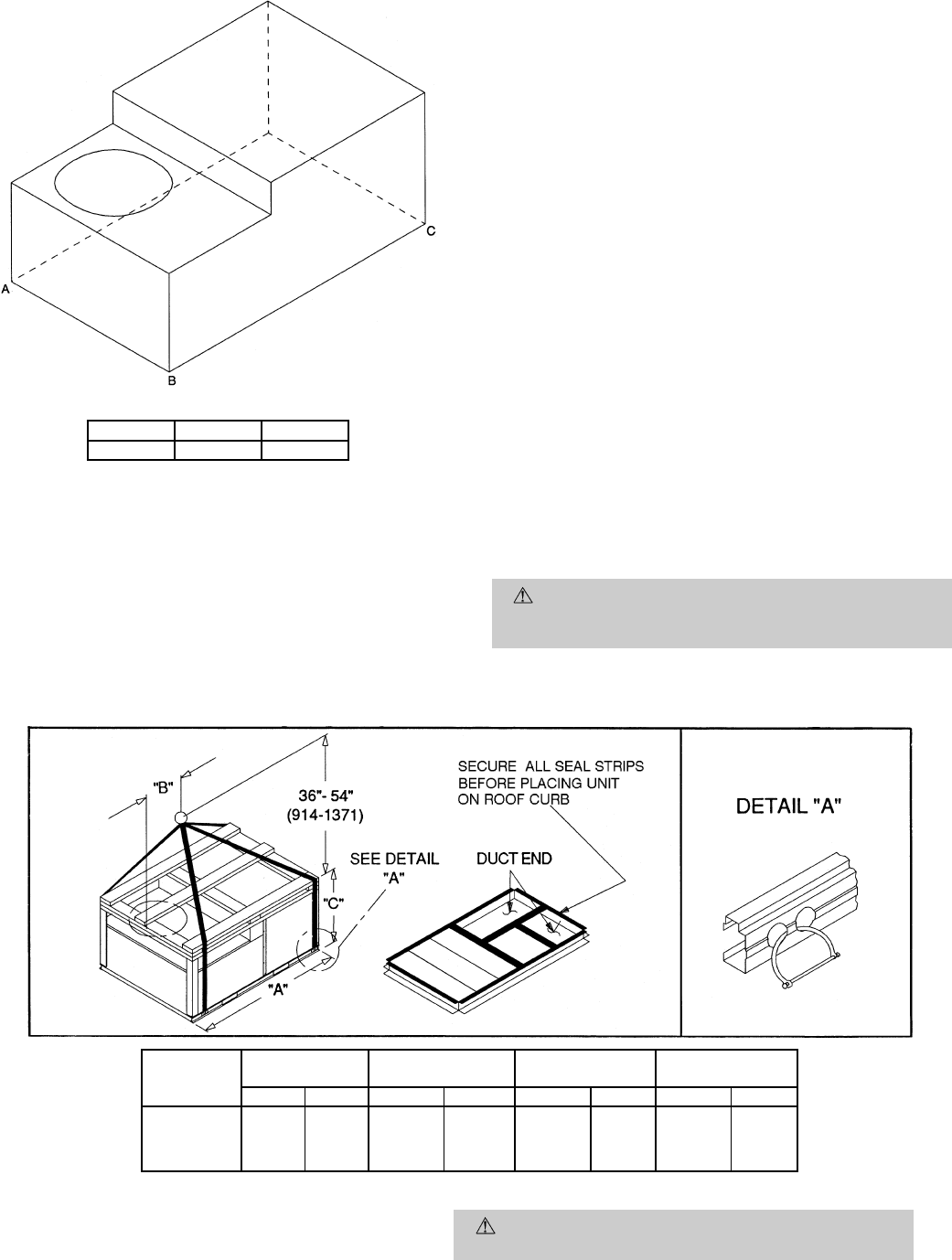

UNIT

MAX

WEIGHT

‘‘A’’ ‘‘B’’ ‘‘C’’

Lb Kg in. mm in. mm in. mm

558D036 415 188

73.69 1872 35.00 889 33.35 847

558D048 425 193

558D060 445 202

558D072 520 236

NOTES:

1. Dimension in ( ) is in millimeters.

2. Hook rigging shackles through holes in base rail, as shown in

detail ‘‘A.’’ Holes in base rails are centered around the unit

center of gravity. Use wooden top skid when rigging to pre-

vent rigging straps from damaging unit.

3. Weights do not include economizer. See Table 1 for econo-

mizer weights.

CAUTION: All panels must be in place when

rigging.

Fig. 6 — Rigging Details

—6—