4

Refer to Fig. 3 and install filter drier as follows:

1. Braze 5--in. liquid tube to the indoor coil.

2. Wrap filter drier with damp cloth.

3. Braze filter drier to above 5--in. (127 mm) liquid tube.

Flow arrow must point towards indoor coil.

4. Connect and braze liquid refrigerant tube to the filter drier.

A05178

Fig. 3 -- Liquid Line Filter Drier

Evacuate Refrigerant Tubing and Indoor Coil

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Never use the system compressor as a vacuum pump.

Refrigerant tubes and indoor coil should be evacuated using the

recommended deep vacuum method of 500 microns. The alternate

triple evacuation method may be used (see triple evacuation

procedure in service manual). Always break a vacuum with dry

nitrogen.

Deep Vacuum Method

The deep vacuum method requires a vacuum pump capable of

pulling a vacuum of 500 microns and a vacuum gage capable of

accurately measuring this vacuum depth. The deep vacuum method

is the most positive way of assuring a system is free of air and

liquid water. A tight dry system will hold a vacuum of 1000

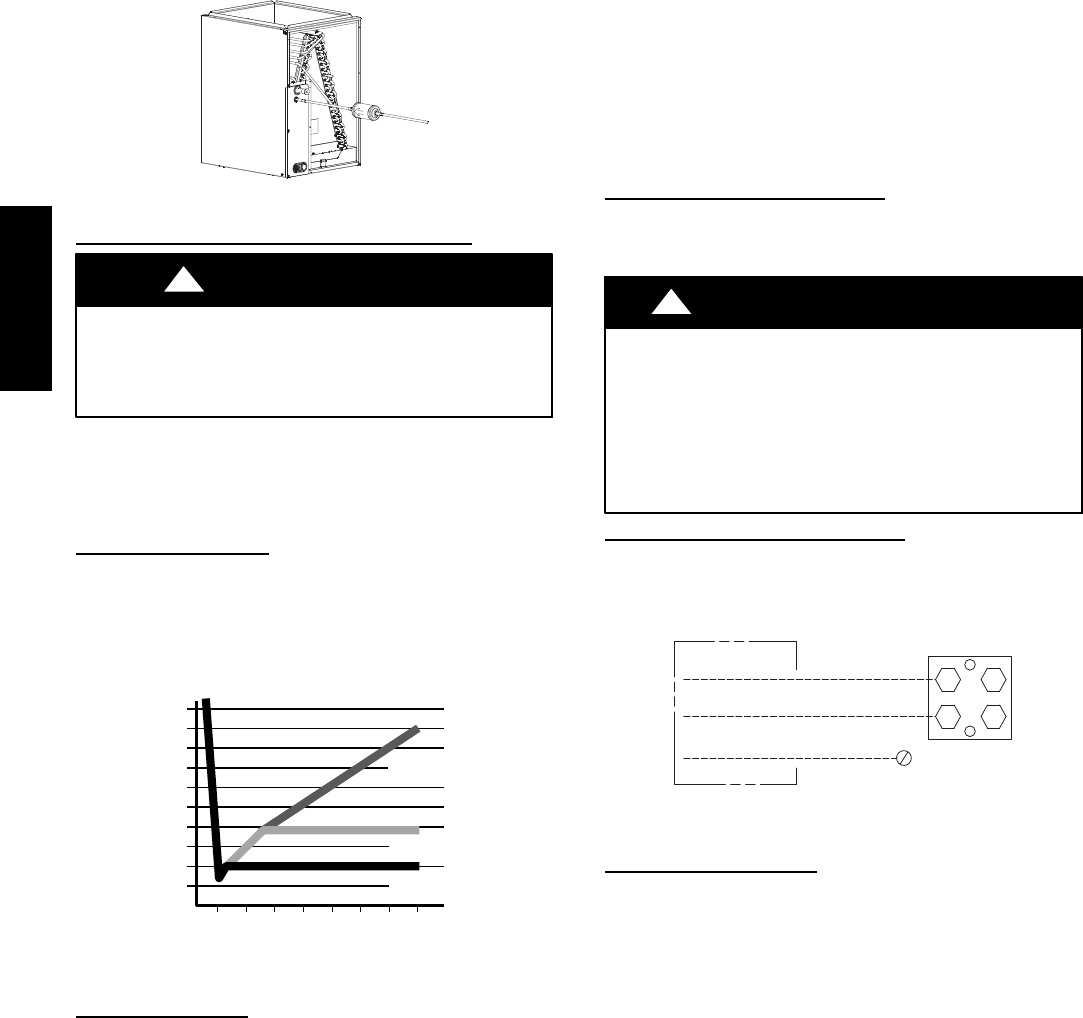

microns after approximately 7 minutes. See Fig. 4.

500

MINUTES

01234567

1000

1500

LEAK IN

SYSTEM

VACUUMTIGHT

TOO WET

TIGHT

DRY SYSTEM

2000

MICRONS

2500

3000

3500

4000

4500

5000

A95424

Fig. 4 -- Deep Vacuum Graph

Final Tubing Check

IMPORTANT: Check to be certain factory tubing on both indoor

and outdoor unit has not shifted during shipment. Ensure tubes are

not rubbing against each other or any sheet metal or wires. Pay

close attention to feeder tubes, making sure wire ties on feeder

tubes are secure and tight.

Make Electrical Connections

Be sure field wiring complies with local and national fire, safety,

and electrical codes, and voltage to system is within limits shown

on unit rating plate. Contact local power company for correction of

improper voltage. See unit rating plate for recommended circuit

protection device.

NOTE: Operation of unit on improper line voltage constitutes

abuse and could affect unit reliability. See unit rating plate. Do not

install unit in system where voltage may fluctuate above or below

permissible limits.

NOTE: Use copper wire only between disconnect switch and unit.

NOTE: Install branch circuit disconnect of adequate size per NEC

to handle unit starting current. Locate disconnect within sight from

and readily accessible from unit, per Section 440--14 of NEC.

Route Ground and Power Wires

Remove access panel to gain access to unit wiring. Extend wires

from disconnect through power wiring hole provided and into unit

control box.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or

death.

The unit cabinet must have an uninterrupted or unbroken

ground to minimize personal injury if an electrical fault should

occur. The ground may consist of electrical wire or metal

conduit when installed in accordance with existing electrical

codes.

Connect Ground and Power Wires

Connect ground wire to ground connection in control box for

safety. Connect power wiring to contactor as shown in Fig. 5.

DISCONNECT

PER N. E. C. AND/OR

LOCAL CODES

CONTACTOR

GROUND

LUG

FIELD GROUND

WIRING

FIELD POWER

WIRING

A91056

Fig. 5 -- Line Connections

Connect Control Wiring

This unit is capable of communication with an Evolution Control,

or will operate using standard 24v 2--stage thermostat. Route 24--v

control wires through control wiring grommet and connect leads to

control board. When an Evolution User Interface is available,

connect A, B, C and D connections only. If a 2--stage thermostat is

used, connect to the R, C, Y1, and Y2 connections. Refer to the

wiring label to further clarification.

Use No. 18 AWG color--coded, insulated (35_C minimum) wire. If

thermostat is located more than 100 ft. (30.48 m) from unit, as

measured along the control voltage wires, use No. 16 AWG

color--coded wire to avoid excessive voltage drop.

All wiring must be NEC Class 1 and must be separated from

incoming power leads.

Use furnace transformer, fan coil transformer, or accessory

transformer for control power, 24v/40va minimum.

NOTE: Use of available 24v accessories may exceed the

minimum 40va power requirement. Determine total transformer

loading and increase the transformer capacity or split the load with

an accessory transformer as required.

187B / 180B