3

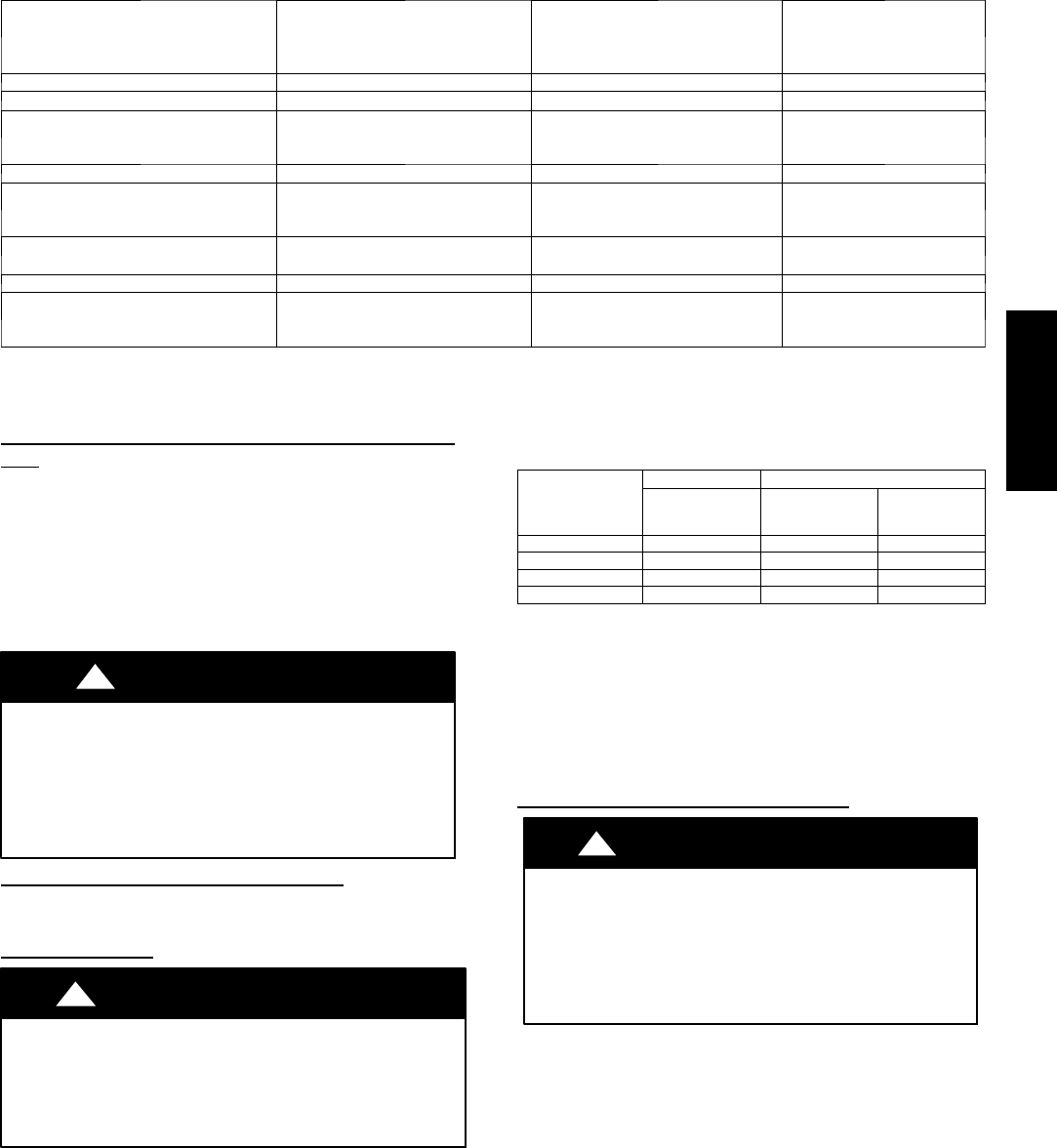

Table 1 – Accessory Usage

ACCESSORY

REQUIRED FOR

LOW --- AMBI ENT C OOLING

APPLICATIONS

(Below 55°F/12.8_C)

REQUIRED FOR LONG LINE

APPLICATIONS*

REQUIRED FOR SEA COAST

APPLICATIONS

(Within 2 miles/3.22 km )

Compressor Start Assist Kit No Yes No

Crankc ase Heater Standard Standard Standard

Evaporator F reeze Protect ion

Standard with Evolutiont Control

(Low Ambient n ot all owed with

non---communicating thermostat)

No No

Liquid---Line Solenoid Valve No No No

Low---Ambient Control

Standard with Ev olution Control

(Low ambient not allowed with

non---communicating thermostat)

No No

Puron Refrigera nt Balance Port Hard---

ShutOff TXV

Yes{

Yes{

Yes{

Support Feet Recommended No Recommended

Winter Start Control

Standard with Ev olution Control

(Low Ambient not all owed with

non---communicating thermostat)

No No

* For tubing set l engths between 80 and 200 ft. (24.38 and 60.96 m) horizontal or 35 ft. (10.7 m) vertical differential (total equivalent l ength), r efer to the Long

Line Guideline—Air Conditioners and Heat Pumps using Puron® Refrigerant.

{ Requiredon all indoor units. Standard on all new Puron refrigerant fan coilsand furnace coils.

Outdoor Unit Connected to Factory Approved Indoor

Unit

Outdoor unit contains correct system refrigerant charge for

operation with factory approved AHRI rated indoor unit when

connected by 15 ft. (4.57 m) of field--supplied or factory--accessory

tubing, and factory supplied filter drier. Check refrigerant charge

for maximum efficiency.

NOTE: If the indoor furnace coil width is more than the furnace

casing width, refer to the indoor coil Installation Instructions for

transition requirements.

!

WARNING

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this warning could result in personal injury

or equipment damage.

PuronR refrigerant systems operate at higher pressures than

standard R--22 systems. Do not use R--22 service equipment

or components on PuronR refrigerant equipment.

Refrigerant Tubing Connection Outdoor

Connect vapor and liquid tubes to fittings on vapor and liquid

service valves (see Table 2.) Use refrigerant grade tubing.

Sweat Connection

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Service valves must be wrapped in a heat--sinking material

such as a wet cloth while brazing.

Use refrigeration grade tubing. Service valves are closed from

factory and ready for brazing. After wrapping service valve with a

wet cloth, braze sweat connections using industry accepted

methods and materials. Consult local code requirements.

Refrigerant tubing and indoor coil are now ready for leak testing.

This check should include all field and factory joints.

Table 2 – Refrigerant Connections and Recommended Liquid

and Vapor Tube Diameters (In.)

UNIT SIZE

LIQUID RATED VAPOR*

Connection

&Max.Tube

Diameter

Connection

Diameter

Tube

Diameter

024 3/8 3/4 3/4

036 3/8 7/8 7/8

048 3/8 7/8 1-1/8

060 3/8 7/8 1-1/8

* Units are rated with 25 ft. (7.6 m) of lineset. See Product Data sheet for

performance data when usingdifferent size and length linesets.

Notes:

1. Do not apply capillary tube or fixed orifice indoor coils to these units.

2. For Tubing Set lengths between 80 and 200 ft. (24.38 an d 60.96 m)

horizontal or 35 ft. (10.7 m) vertical differential 250 f t. (76.2 m) Total

Equivalent Length), refer to the Residential Piping and Longline Guide

line--- Air Conditioners andHeat Pumps using Puron refrigerant.

3. For alternate liquid line options on 18---42 size units, see Product Data or

Residential Piping and Application Guideline

Install Liquid--Line Filter Drier Indoor

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

1. Installation of filter drier in liquid line is required.

2. Filter drier must be wrapped in a heat--sinking material

such as a wet cloth while brazing.

187B / 180B