10

cutout trips for three consecutive cycles, then unit operation is

locked out for 4 hours and the appropriate fault code is displayed.

No 230V at Compressor

If the compressor voltage is not sensed when the compressor

should be starting, the appropriate contactor may be stuck open or

there is a wiring error. The control will flash the appropriate fault

code. Check the contactor and control box wiring.

Troubleshooting units for proper switching

between low & high stages

Check the suction pressures at the service valves. Suction pressure

should be reduced by 3--10% when switching from low to high

capacity.

NOTE: The liquid pressures are very similar between low and

high stage operation so liquid pressure should not be used for

troubleshooting.

Compressor current should increase 20--45% when switching from

low to high stage. The compressor solenoid, when energized in

high stage, should measure 24vac. When the compressor is

operating in low stage the 24v DC compressor solenoid coil is

de--energized. When the compressor is operating in high stage, the

24v DC solenoid coil is energized. The solenoid plug harness that

is connected to the compressor has an internal rectifier that

converts the 24v DC signal to 24v AC.

NOTE: DO NOT INSTALL A PLUG WITHOUT AN

INTERNAL RECTIFIER.

Unloader Test Procedure

The unloader is the compressor internal mechanism, controlled by

the DC solenoid, that modulates between high and low stage. If it

is suspected that the unloader is not working, the following

methods may be used to verify operation.

1. Operate the system and measure compressor amperage.

Cycle the unloader on and off at 30 second plus intervals at

the UI (from low to high stage and back to low stage). Wait

5 seconds after staging to high before taking a reading. The

compressor amperage should go up or down at least 20 per-

cent.

2. If step one does not give the expected results, remove the

solenoid plug from the compressor and, with the unit run-

ning and the UI (or Thermostat) calling for high stage, test

the voltage output at the plug with a DC voltmeter. The

reading should be 24 volts DC.

3. If the correct DC voltage is at the control circuit molded

plug, measure the compressor unloader coil resistance. The

resistance should be 32 to 60 ohms depending on com-

pressor temperature. If the coil resistance is infinite, much

lower than 32 ohms, or is grounded, the compressor must

be replaced.

MAJOR COMPONENTS

2--Stage Control

The 2--stage control board controls the following functions:

— Compressor high and low stage operation

— Outdoor fan motor operation

— Low ambient cooling

— Compressor external protection

— Pressure switch monitoring

— Time delays

Field Connections

On models with non--communicating (non--Evolution) system, the

2--stage control receives 24vac low--voltage control system inputs

through the R, C, Y1, and Y2 connections located at the bottom of

the control board (see Fig. 6). The OD units can be controlled

using a standard 2--stage thermostat or Evolution User Interface.

2--Stage Compressor

The 2--stage compressor contains motor windings that provide

2--pole (3500 RPM) operation. Refer to Table 4 for correct

winding resistance.

Compressor Internal Relief

The compressor is protected by an internal pressure relief (IPR)

which relieves discharge gas into compressor shell when

differential between suction and discharge pressures exceeds 550 --

625 psi The compressor is also protected by an internal overload

attached to motor windings.

Compressor Control Contactor

The contactor has a 24 volt coil. The electronic control board

controls the operation of the appropriate contactor.

TEMPERATURE THERMISTORS

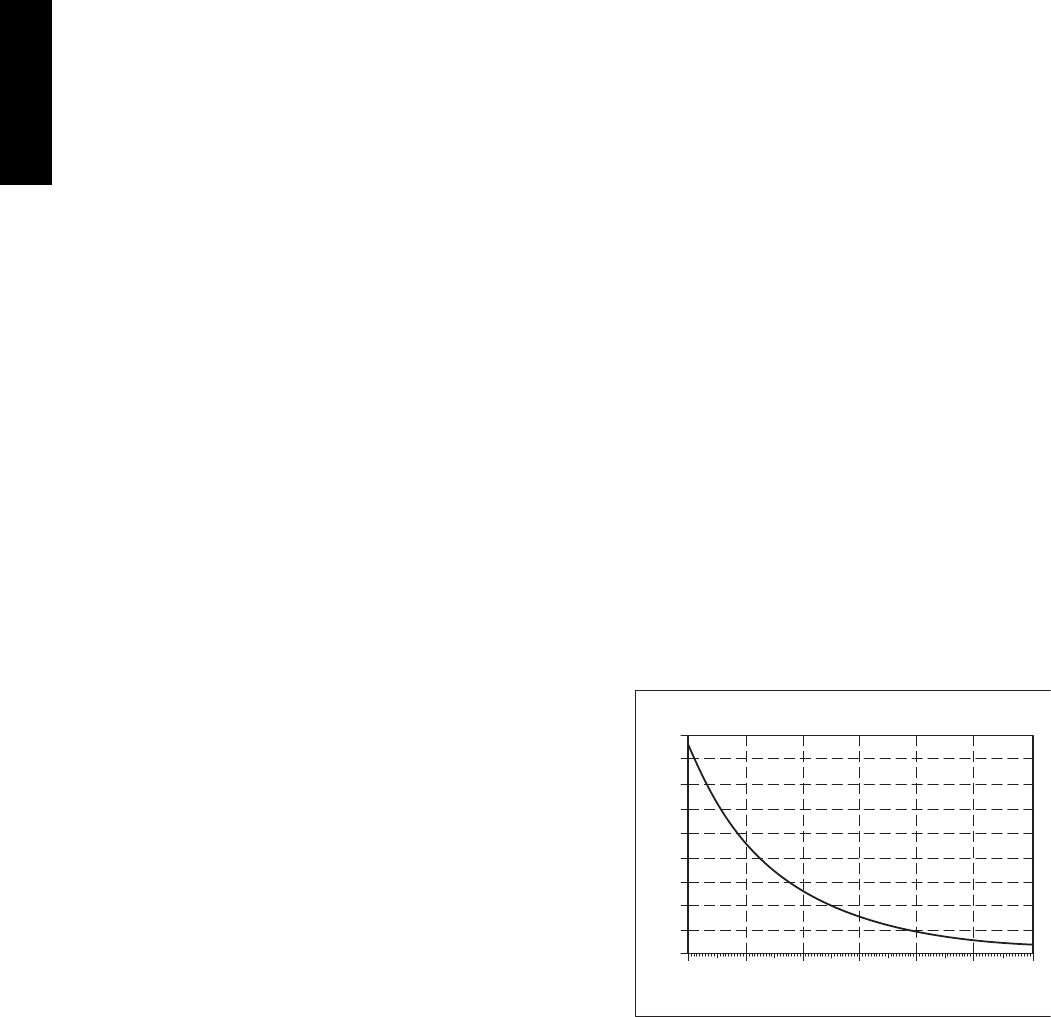

Thermistors are electronic devices which sense temperature. As the

temperature increases, the resistance decreases. Thermistors are

used to sense outdoor ambient (OAT) and coil temperature (OCT).

Refer to Fig. 7 for resistance values versus temperature. If the

outdoor ambient or coil thermistor should fail, the control will

flash the appropriate fault code (see Table 6.)

IMPORTANT: Outdoor air thermistor and coil thermistor are

factory mounted in the final locations. Check to insure thermistors

are mounted properly per Fig. 8 and Fig. 9.

Thermistor Sensor Comparison

The control continuously monitors and compares the outdoor air

temperature sensor and outdoor coil temperature sensor to ensure

proper operating conditions. The comparison is:

— If the outdoor air sensor indicates 10_F (5.56_C) warmer

than the coil sensor (or) the outdoor air sensor indicates

20_F(11.11_C) cooler than the coil sensor, the sensors

are out of range.

— If the sensors are out of range, the control will flash the

appropriate fault code as shown in Table 6.

— The thermistor comparison is not performed during low

ambient cooling or defrost operation.

Failed Thermistor Default Operation

Factory defaults have been provided in the event of failure of

outdoor air thermistor and/or coil thermistor.

If the OAT sensor should fail, low ambient cooling will not be

allowed and the one minute outdoor fan--off delay will not occur.

If the OCT sensor should fail, low ambient cooling will not be

allowed.

OAT Thermistor must be locked in place with spherical nib end

facing towards the front of the control box

0

10

20

30

40

50

60

70

80

90

0

(-17.77)

20

(-6.67)

40

(4.44)

60

(15.56)

80

(26.67)

100

(37.78)

120

(48.89)

TEMPERATURE °F (°C)

RESISTANCE (KOHMS)

THERMISTOR CURVE

A08054

Fig. 7 -- Resistance Values Versus Temperature

187B / 180B