Page 14

BRADFORD WHITE CORP.

diaphragm-type expansion tank, and a hydronic flow

check in the system supply loop. Minimum fill pressure

must be 12psig (82.7kPa). Install shutoff valves where

required by code.

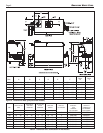

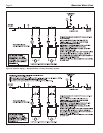

Suggested piping diagrams are shown (see Figures

6 through 14). These diagrams are meant only as a

guide. Components required by local codes must be

properly installed.

4A.2 Cold Water Make-Up — Boiler

1. Connect the cold water supply to the inlet

connection of an automatic fill valve.

2. Install a suitable back flow preventer between the

automatic fill valve and the cold water supply.

3. Install shut off valves where required.

NOTE: The boiler, when used in connection with a

refrigeration system, must be installed so the chilled

medium is piped in parallel with the boiler with

appropriate valves to prevent the chilled medium from

entering the boiler.

The boiler piping system of a hot water heating

boiler connected to heating coils located in air handling

appliances where they may be exposed to refrigerated

air circulation must be equipped with flow control

valves or other automatic means to prevent gravity

circulation of the boiler water during the cooling cycle.

A boiler installed above radiation level, or as

required by the authority having jurisdiction, must be

provided with a low water cutoff device either as a part

of the boiler or at the time of boiler installation.

4A.3 Water Flow Requirements — Boiler

A hydronic heating (closed loop) application re-

circulates the same fluid in the piping system. As a

result, no new minerals or oxygen is introduced into the

system. To ensure a proper operating temperature

leading to long boiler life, a flow rate has been

established based on the fluid temperature rise for this

specific size boiler.

Pump-mounted boilers can be ordered for use in

primary secondary piping systems. The pumps used are

sized for the headloss through the heater, plus 30 feet

(9.1m) of full-sized piping (same size as boiler outlet)

and a normal number of fittings.

Table 8 specifies water flow rates for boilers,

which will enable the user to size a pump. The headloss

shown is for the heater only, and the user will need to

add the headloss of the system piping to properly size

the pump.

The minimum inlet water temperature for the Brute

Deluxe is 120°F (49°C) to avoid condensing on the

copper coils.

4A.4 Freeze Protection — Boiler

Boiler installations are not recommended in areas

where the danger of freezing exists unless proper

precautions are made for freeze protection. A non toxic,

heating system, anti-freeze may be added to the hydronic

system provided that the concentration does not exceed

50% and the anti freeze contains an anti foamant. When

a 50/50 mixture is used, increase the water flow

requirements by 15%, and increase the headloss

requirements by 20%.

Power outage, interruption of gas supply, failure of

system components, activation of safety devices, etc., may

prevent a boiler from firing. Any time a boiler is subjected

to freezing conditions, and the boiler is not able to fire, and/

or the water is not able to circulate, there is a risk of

freezing in the boiler or in the pipes in the system. When

water freezes, it expands. This can result in bursting of

pipes in the system, or damage to the boiler, which could

result in leaking or flooding conditions.

IMPORTANT NOTES: Different glycol products may

provide varying degrees of protection. Glycol products

must be maintained properly in a heating system, or they

may become ineffective. Consult the glycol specifications,

or the glycol manufacturer, for information about specific

products, maintenance of solutions, and set up according

to your particular conditions.

SECTION 4B.

Water Connections —

Water Heater

4B.1 Water System Piping —

Water Heater

Hot water piping should be supported by suitable

hangers or floor stands. Do not support piping with this

appliance. Due to expansion and contraction of copper

pipe, consideration should be given to the type of

hangers used. Rigid hangers may transmit noise through

the system resulting from the piping sliding in the

hangers. It is recommended that padding be used when

rigid hangers are installed.

The Brute Deluxe can be used with several different

types of readily available storage tanks. A pump draws

water from the storage tank and pumps the water through

the heater and back into the tank. Pump-mounted units have

a circulating pump built into the water heater. The pumps

used are sized for the headloss through the heater, plus 30

feet (9.1m) of full-sized piping (same size as boiler outlet)

and a normal number of fittings. Pumps used on pump-

mounted unit are sized for soft/normal or hard water, so

make sure a pump-mounted unit matches the water quality

of the installation.

Pipe the outlet from the heater’s relief valve such

that any discharge from the relief valve will be

conducted to a suitable place for disposal when relief

occurs. Do not reduce line size or install any valves in

this line. The line must be installed to allow complete

drainage of both the valve and the line.

Suggested piping diagrams are shown in Figures 10