9

Form 6104 BCF14N-R0299

Instruction Manual – Model CF1400 Oil Burner

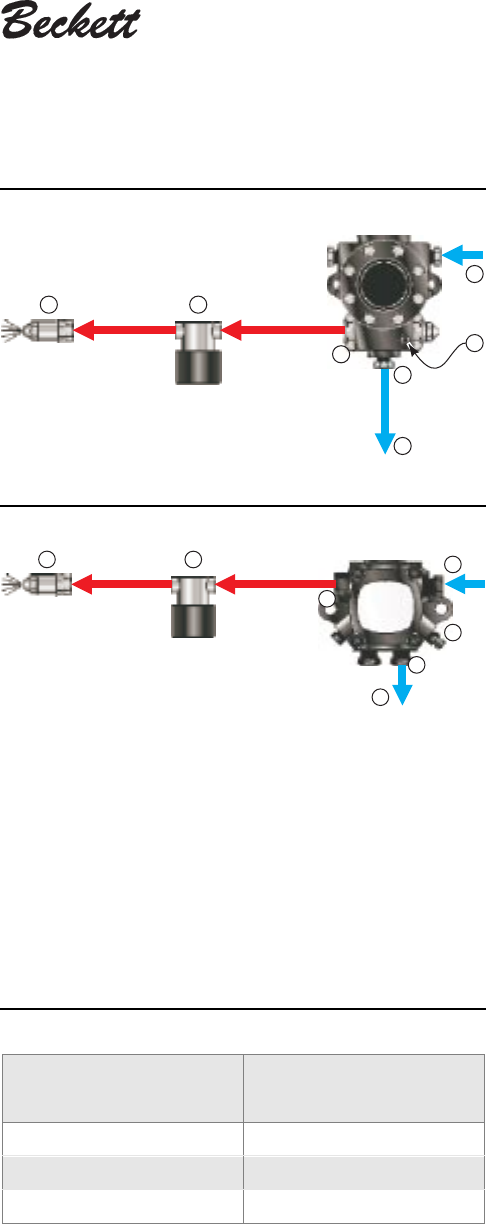

Figure 9a – Two-pipe oil flow with “H” pump

300 psig

k

g

1413ao

d

a

b

p

300 psig

c

Figure 9b – Two-pipe oil flow with “B” pump

d

b

g

p

300 psig

300 psig

c

1423ao

a

k

a Return port

b Nozzle port

c Oil valve

d Nozzle & adapter

Legend

g Inlet port

k Return line to oil tank

p Air bleed valve

Table 3 – Fuel unit gearset capacities

Fuel unit

model number

Gearset capacity

(gallons per hour)

B2TA8245 21

H3PAN-C150H 61

H4PAN-C151H 69

for the fuel unit gearset capacity - the rate at which fuel is

recirculated when connected to a two-pipe system. Size

two-pipe oil lines based on this flow rate.

• Use continuous lengths of heavy-wall copper tubing,

routed under the floor where possible. Do not attach fuel

lines to the appliance or to floor joists if possible. This will

reduce vibration and noise transmission problems.

• Install an oil filter sized to handle the fuel unit gearset flow

capacity (Table 3) for two-pipe systems. Size the filter

for the firing rate for one-pipe systems. Locate the filter

immediately adjacent to the burner fuel unit.

• Install two high-quality shut-off valves in accessible loca-

tions on the oil supply line. Locate one valve close to the

tank. Locate the other valve close to the burner, upstream

of the fuel filter.

❏ Burner fuel flow

• One-pipe systems – See Figure 8 for the fuel flow path.

• Figure 8a is based on type H fuel units.

• Figure 8b is based on type B fuel units.

• Oil supply connects to one of the fuel unit inlet ports.

• Two-pipe systems – See Figure 9 for the fuel flow paths

for two-pipe oil systems.

• Figure 9a is based on type H fuel units.

• Figure 9b is based on type B fuel units.

• Oil supply connects to one of the fuel unit inlet ports.

Oil return connects to the fuel unit return port. (Install

the by-pass plug in the fuel unit for two-pipe sys-

tems.

)

• Nozzle pressure – The fuel unit nozzle port pressure is

factory set at 300 psig. Some original equipment manufac-

turer burner applications may call for a lower pressure to

obtain a required firing rate. Do not change this pressure

unless directed to do so by the appliance manufacturer.