8 6104 BCF5 R07

50001

End view Side view

3/16” - 7/32”

gap

1/4” in front

of nozzle

3/16” above

nozzle center

R

P

Q

Install nozzle line assembly

Insert the nozzle line assembly into the burner air tube.

Reference Figure 6.

Slide the secondary adjusting plate (Figure 7, item f) com-

pletely to the left on the indicator adjusting plate (item e).

Finger tighten acorn nut (item c) to secure the two plates

together. Slide both plates completely to the right (Indica-

tor Plate will read 0). Tighten fastener (item d).

Install the spline nut on the end of the nozzle line, leaving

the nut loosely placed so the plates can be moved.

y

y

y

Mount air tube to burner

Insert the air tube into the burner housing. Carefully align

the the four screw holes.

Attach the air tube to the burner using the four provided

screws.

Install nozzle

Install the oil nozzle in the nozzle adapter. Use a 3/4”

open-end wrench to steady the nozzle adapter and a 5/8”

open-end wrench to turn the nozzle. Tighten securely but

do not over-tighten.

Check electrode settings

y

y

y

Adjust the electrode gap and position in relation to the

nozzle to the specifi cations shown in Figure 4.

y

Failure to properly maintain these specifi cations

could cause ignition malfunction, puff-back of

hot gases, heavy smoke, asphyxiation, explo-

sion and fi re hazards.

Maintain Electrode

Specifi cations

Check, and adjust if necessary, the critical dimensions

shown in Figure 5. Verify that the oil tube assembly

and electrodes are in good condition, with no cracks or

damage.

y

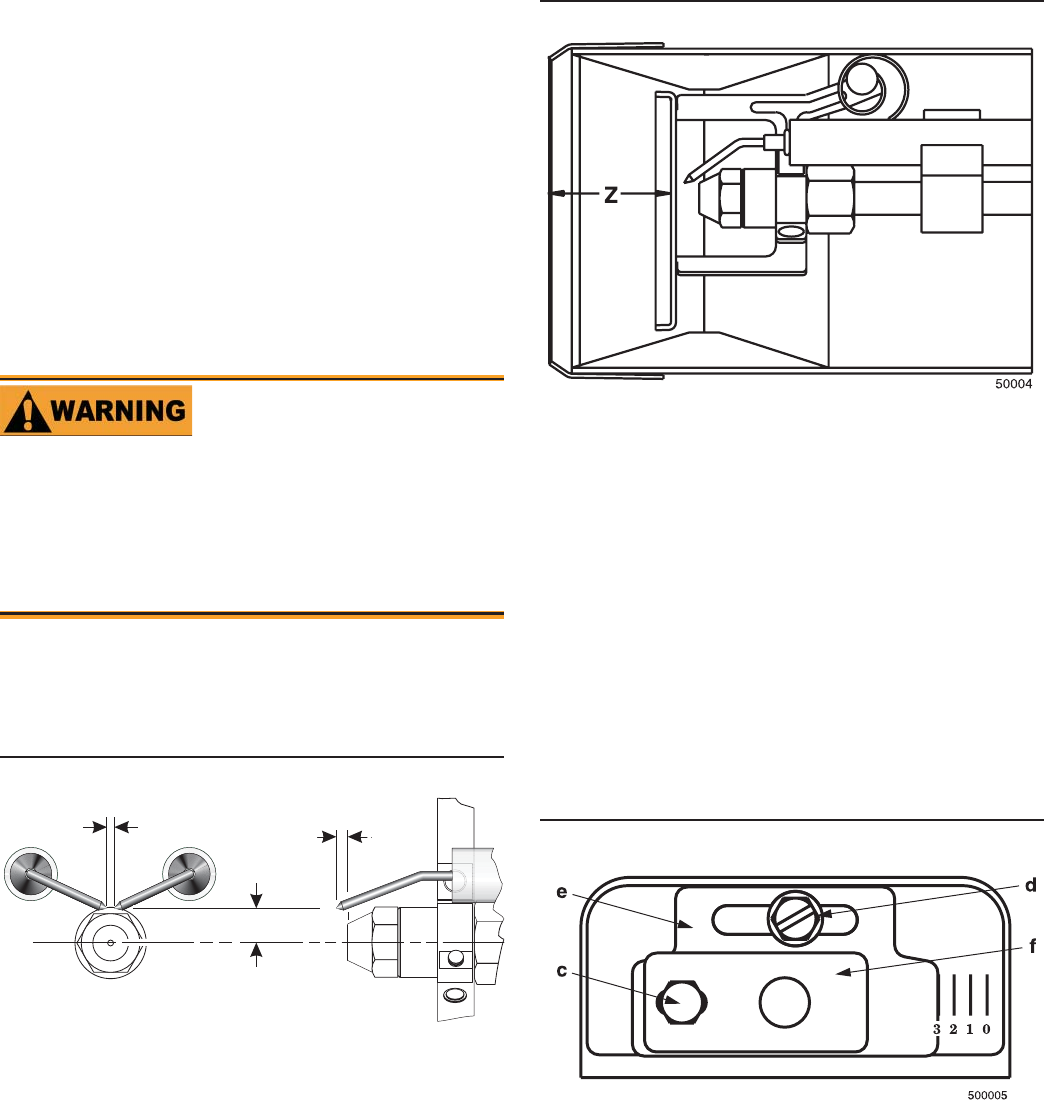

Figure 5 - Nozzle and nozzle line assembly

Set dimension Z

Loosen fastener c in Figure 7. Slide the nozzle line and

plate assembly until dimension Z in Figure 6 is:

CF500 - 1-9/16” ±1/16”

CF800 - 1-3/4” ±1/16”.

When dimension Z (from end of air tube to fl at area of

front face of head) is correctly set, tighten acorn nut

(item c).

Attach the oil line from the oil valve to the nozzle line

end. Tighten securely.

Before proceeding, check dimension Z once again. Loos-

en acorn nut c if necessary to reposition the nozzle line.

Once dimension Z is set, do not loosen the acorn nut

(item) c again. Note that for the setting of fastener d,

refer to Initial Head Position procedure on Page 11.

y

y

y

Figure 7 - Adjusting plate assy.

Legend (Figures 7)

c

Bottom acorn nut

d

Fastener

e

Indicator adjusting plate

f

Secondary adjusting plate

Figure 6 - Nozzle line assembly in burner

Insert burner

Position the burner in the front of the appliance and loosely

tighten the nuts on the mounting studs. The burner should

be pitched downward 2° as shown in Figure 4.

Secure the burner to the appliance by tightening the nuts

on the burner fl ange mounting studs.

y

y

CF500

1-9/16”

CF800

1-3/4”

Legend (Figure 5)

P

Nozzle centerline to electrode tip = 1/4”

Q

Nozzle face to electrode tip = 1/8”

R

Electrode spacing = 5/32” gap