6104 BCF5 R07 5

Fuel supply

The fuel supply piping and tank must provide #1 or #2 fuel

oil at pressure or vacuum conditions suitable for the fuel

unit (oil pump) on the burner. Refer to fuel unit literature

in the literature envelope in the burner carton to verify

allowable suction pressure.

If fuel supply is level with or higher than fuel unit —

When the fuel unit is not required to lift the oil, the

installation is usually suitable for either a one-pipe or two-

pipe oil system. The oil pressure at the inlet of the fuel unit

must not exceed 3 psig.

Refer to the Mount the Burner Section of this manual for

one-pipe or two-pipe fuel supply installation instructions.

If fuel supply is below the fuel unit —

Use a two-pipe oil system when the fuel unit must lift the

oil more than 8 feet if burner is equipped with a B fuel

unit. The return line provided by the two-pipe system is

needed to purge the air from the fuel lines and minimize

the likelihood of air-related problems during operation.

y

y

y

y

Oil Supply Pressure

Control Required

Damage to the pump, fi lter or other compo-

nent seals could cause possible oil leakage

and potential fi re hazard.

The oil supply inlet pressure to the fuel unit cannot

exceed 3 psig.

Do NOT install valves in return line.

Ensure that a pressure-limiting device is installed in

accordance with the latest edition of the NFPA 31.

y

y

y

Nozzle pressure

The fuel unit nozzle port pressure is factory set at 140

psig. Some original equipment manufacturer burner appli-

cations may call for a lower pressure to obtain a required

fi ring rate. Do not change this pressure unless directed to

do so by the appliance manufacturer.

Electrical supply

Verify that the power connections available are correct for

the burner. Refer to Figure 1. All power must be supplied

through fused disconnect switches.

Vent system

The fl ue gas venting system must be in good condition and

must comply with all applicable codes.

y

y

y

Use only nozzles having the brand, fl ow rate (gph),

spray angle and pattern specifi ed by the appliance

manufacturer.

Follow the appliance manufacturer’s specifi cations for

the required pump outlet pressure for the nozzle, since

this affects the fl ow rate.

Nozzle manufacturers calibrate nozzle fl ow rates at

100 psig.

This burner utilizes pressures higher than 100 psig, so

the actual nozzle fl ow rate will be greater than the gph

stamped on the nozzle body. (Example: A 4.00 gph

nozzle at 140 psig = 4.70 gph.

For typical nozzle fl ow rates at various pressures

see accompanying chart.

y

y

y

Incorrect nozzles and fl ow rates could

result in impaired combustion, under-

fi ring, over-fi ring, sooting, puff-back

of hot gases, smoke and potential fi re

or asphyxiation hazards.

Correct Nozzle and Flow

Rate Required

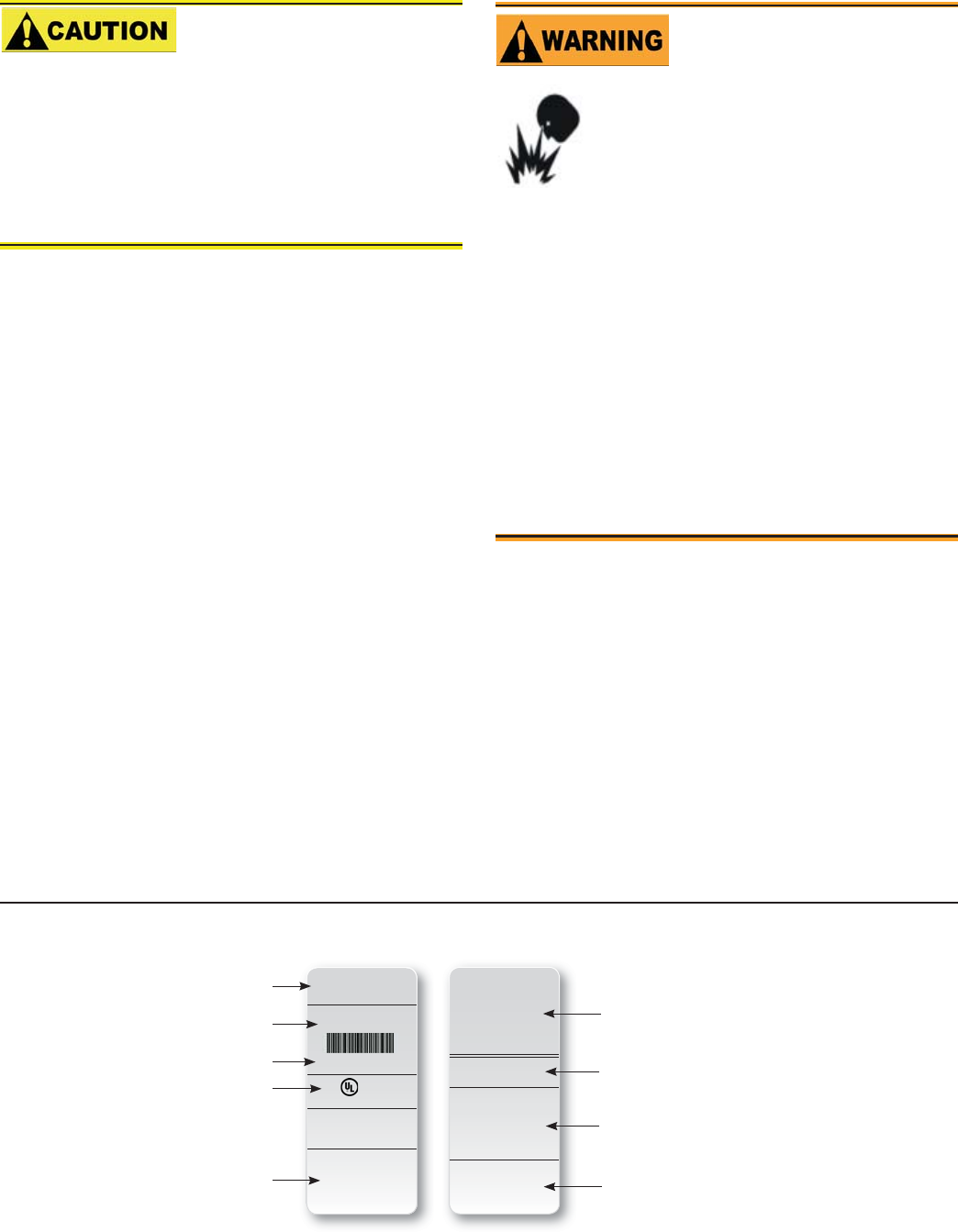

LISTED

(FUEL) BURNER

SERIAL NUMBER

050214-00000

Control Circ: 120V/60Hz 4.5A

Motor Circ: 120V/60Hz 4.0A

Model “XX”

Series (Fuel) Burner

R.W. Beckett Corp.

Elyria, Ohio

Made in the U.S.A.

For use with Group 8 . . .

MP 1192 XX000 R00

X

X

X

X

X

X

XX000 R00

050214-00000

MFR’S SETTINGS

R.W. Beckett Construction & Setting Data

R.W. Beckett Specifi cation

Number and Revision

Boiler Manufacturer and

Model, When Applicable

Additional Codes

General Model Information

Serial Number,Including Date Code

Rating Information

Approval Agency Symbols

Primary Group and Fuel

L0002

Figure 1. Typical Nameplate