6104 BCF5 R07 13

the control will lock out. Press the reset button to reset the

control and return to the functions listed in the previous

step.

Repeat the previous steps if needed, until the pump is

fully primed and the oil is free of bubbles. Then terminate

the call for heat, and the control will resume normal

operation.

Disable function

Any time the motor is running, press and hold the reset

button to disable the burner. The burner will remain off as

long as the button is held and will return to standby when

released.

CAD cell resistance check

While the burner is fi ring, and after the ignition has been

turned off, press and release the reset button (hold 1/2 sec-

ond or less) to check the cad cell resistance. The LED will

fl ash 1 to 4 times, depending on the cad cell resistance

(refer to the table below).

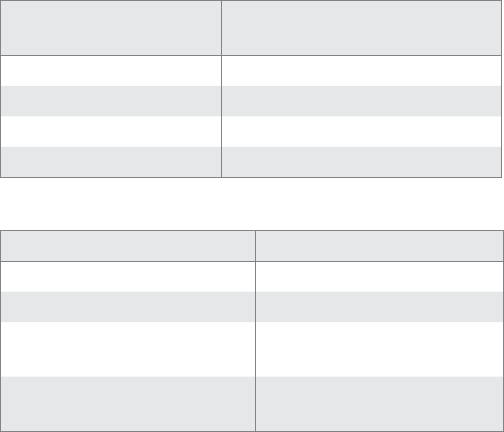

Number of LED

fl ashes

Cad Cell Resistance (ohms)

1 Strong (0 to 400)

2 Normal (400 to 800)

3 Weak (800 to 1600)

4 Poor (1600 or higher)*

* Lockout is likely to occur.

LED Indicator Status

On Flame sensed

Off Flame not sensed

Flashing (1/2 sec off - 1/2

sec on)

Lockout/Restricted

Lockout

Flashing (2 sec off - 2 sec

on)

Recycle

Set combustion using instruments

Allow the burner to run for approximately 5 to 10 minutes.

Set the stack or over-fi re draft to the level specifi ed by the

appliance manufacturer.

Natural Draft Applications; typically over-fi re draft

is -0.01” or -0.02” w.c.

Direct Venting; typically may not require draft adjust-

ment.

High Effi ciency/Positive Pressure Appliances; also

vary from traditional appliances (see manufacturer’s

recommendations).

Follow these four steps to properly adjust the burner:

y

y

y

1.

2.

y

y

y

3.

Step 1: Adjust the air shutter/band until a trace of smoke

is achieved.

Step 2: At the trace of smoke level, measure the CO

2

(or O

2

) . This is the vital reference point for further

adjustments. Example: 13.5% CO

2

(2.6% O

2

)

Step 3: Increase the air to reduce the CO

2

by 1.5 to

2 percentage points. (O

2

will be increased by

approximately 2.0 to 2.7 percentage points.)

Example: Reduce CO

2

from 13.5% to 11.5% (2.6%

to 5.3% O

2

).

Step 4: Recheck smoke level. It should be Zero.

This procedure provides a margin of reserve air

to accommodate variable conditions.

If the draft level has changed, recheck the

smoke and CO

2

(or O

2

) levels and readjust the

burner, if necessary

Once combustion is set, tighten all fasteners on air band, air

shutter and escutcheon plate.

Start and stop the burner several times to ensure satisfactory

operation. Test the primary control and all other appliance

safety controls to verify that they function according to the

manufacturer’s specifi cations.

Check the breech draft pressure against the appliance man-

ufacturer’s recommended setting (typically + 0.1” W.C.). If

the breech pressure is higher or lower than recommended

level, adjust the appliance breech damper to achieve the

specifi ed setting. Recheck the smoke and CO

2

(or O

2

) levels.

Adjust burner air if necessary.

y

y

4.

5.

6.