6104 BCF35 R11 Page 5

The fuel unit nozzle port pressure is factory set at 300

psig. Some original equipment manufacturer burner

applications may call for a lower pressure to obtain a

required fi ring rate. Do not change this pressure unless

directed to do so by the appliance manufacturer.

Electrical Supply

Verify that the power connections available are correct

for the burner. Refer to Figure 1. All power must be

supplied through fused disconnect switches.

Vent System

The fl ue gas venting system must be in good condition

and must comply with all applicable codes.

Nozzle Pressure

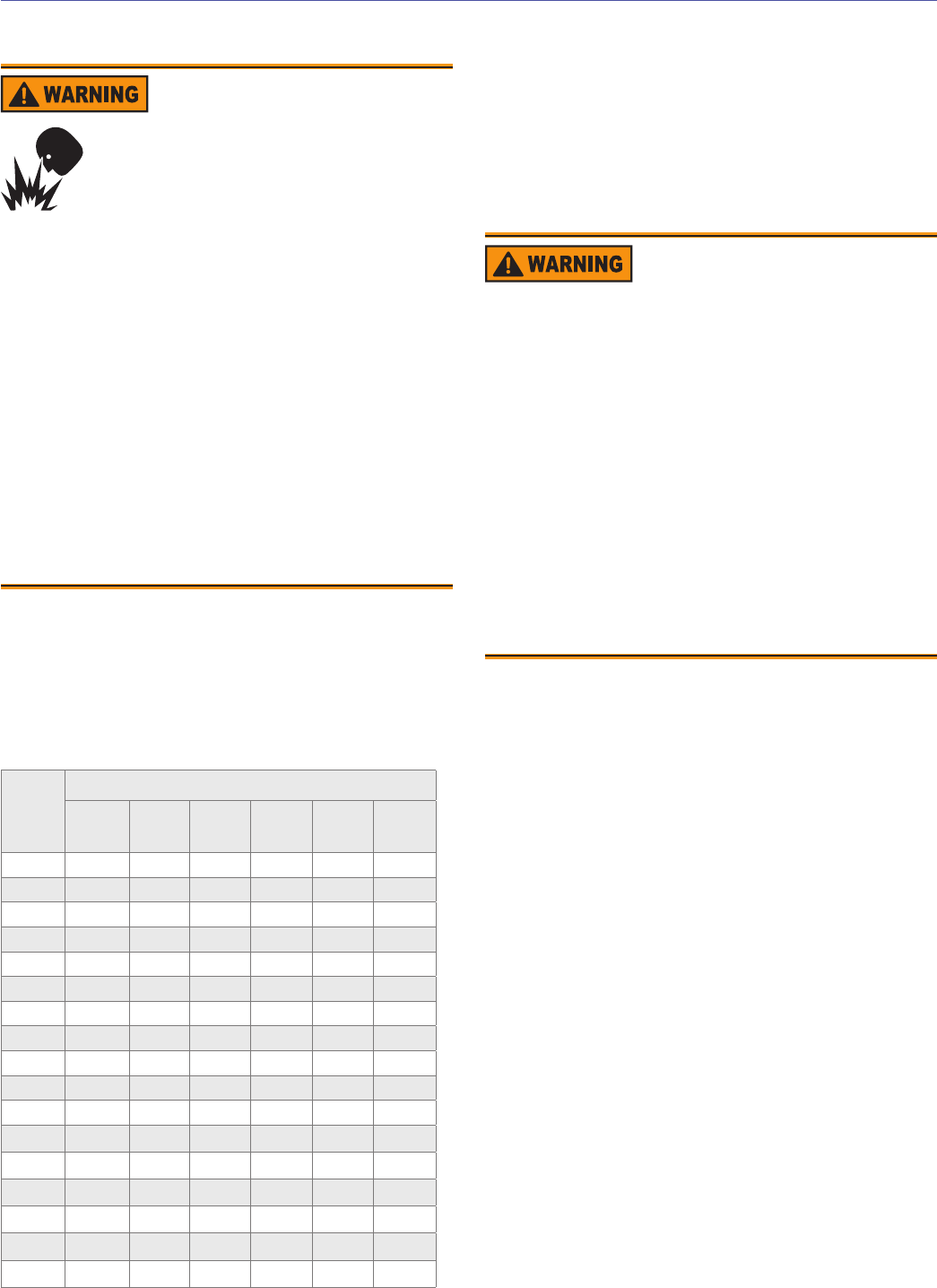

Table 1 - Nozzle Capacities

Rated

gph

@ 100

psig

Pressure - Pounds per square inch

125 150 175 200 250 300

5.00 5.59 6.13 6.61 7.07 7.50 8.66

5.50 6.15 6.74 7.27 7.78 8.70 9.54

6.00 6.71 7.33 7.94 8.48 9.49 10.40

6.50 7.26 7.96 8.60 9.20 10.30 11.25

7.00 7.82 8.56 9.25 9.90 11.06 12.12

7.50 8.38 9.19 9.91 10.60 11.85 13.00

8.00 8.94 9.80 10.58 11.31 12.65 13.85

8.50 9.50 10.45 11.27 12.06 13.40 14.70

9.00 10.06 11.02 11.91 12.73 14.20 15.60

9.50 10.60 11.70 12.60 13.50 15.00 16.45

10.00 11.18 12.25 13.23 14.14 15.81 17.32

10.50 11.74 12.85 13.90 14.85 16.60 18.18

11.00 12.30 13.47 14.56 15.55 17.39 19.05

12.00 13.42 14.70 15.87 16.97 18.97 20.78

12.50 13.98 15.31 16.54 17.68 19.76 21.65

13.00 14.54 15.92 17.20 18.38 20.55 22.52

13.50 15.10 16.53 17.85 19.09 21.34 23.38

Verify Burner Components

Burner nameplate (Figure 1), Model CF2500A/

CF2500/CF3500A

Air tube assembly

Mounting fl ange kit

Pedestal mounting assembly kit (recommended)

Oil nozzle, per Table 1 — Use only 45° to 70°

solid pattern nozzles unless otherwise shown by

appliance manufacturer or on the burner nameplate

rating label.

The CF2500A, CF2500, and CF3500A are dual nozzle

burners. To select the nozzles, use half of the maximum

fi ring rate and select a nozzle under the 300 psig column.

Select the corresponding nozzle from column 1 (Rated gph

@ 100 psig) two nozzles will be required.

Example: a 5.00 gph nozzle at 300 psig = 8.66 gph

Verify Firing Rate

Refer to appliance manufacturer’s instructions (if available)

for fi ring rate and nozzle selection. Otherwise, the maximum

recommended fi ring rate for the burner depends on the length

of the fi ring chamber and the distance from the burner center

to the chamber fl oor. Verify that the chamber dimensions are at

least as large as the minimum values given in Figure 2. If the

appliance dimensions are smaller than recommended, reduce

the fi ring rate accordingly.

○

○

○

○

○

Correct Nozzle and Flow

Rate Required

Incorrect nozzles and fl ow rates could

result in impaired combustion, under-

fi ring, over-fi ring, sooting, puff-back of

hot gases, smoke and potential fi re or

asphyxiation hazards.

Use only nozzles having the brand, fl ow rate (gph), spray

angle and pattern specifi ed by the appliance manufacturer.

Follow the appliance manufacturer’s specifi cations for the

required pump outlet pressure for the nozzle, since this

affects the fl ow rate.

Nozzle manufacturers calibrate nozzle fl ow rates at

100 psig.

This burner utilizes pressures higher than 100 psig,

so the actual nozzle fl ow rate will be greater than

the gph stamped on the nozzle body.

(Example: A 12.00 gph nozzle at 200 psig = 16.97

gph and at 300 psig = 20.78 gph)

For typical nozzle fl ow rates at various pressures

refer to Table 1.

y

y

y

Fire, Smoke & Asphyxiation

Hazard

Carefully inspect the chimney or exhaust vent

system.

Make sure it is properly sized and in good working

condition.

Follow the instructions supplied by the appliance

manufacturer.

The installation must strictly comply with all

applicable codes, authorities having jurisdiction and

the latest revision of the National Fire Protection

Association Standard NFPA 31 for the installation of

chimneys and vent sizing, (or CSA-B139 and CSA-

B140 in Canada).

Regulation by these authorities take precedence

over the general instructions provided in this

installation manual.

y

y

y

y

y

Section: Pre-installation Checklist