Page 4

Pre-installation Checklist

Combustion Air Supply

Fuel Supply

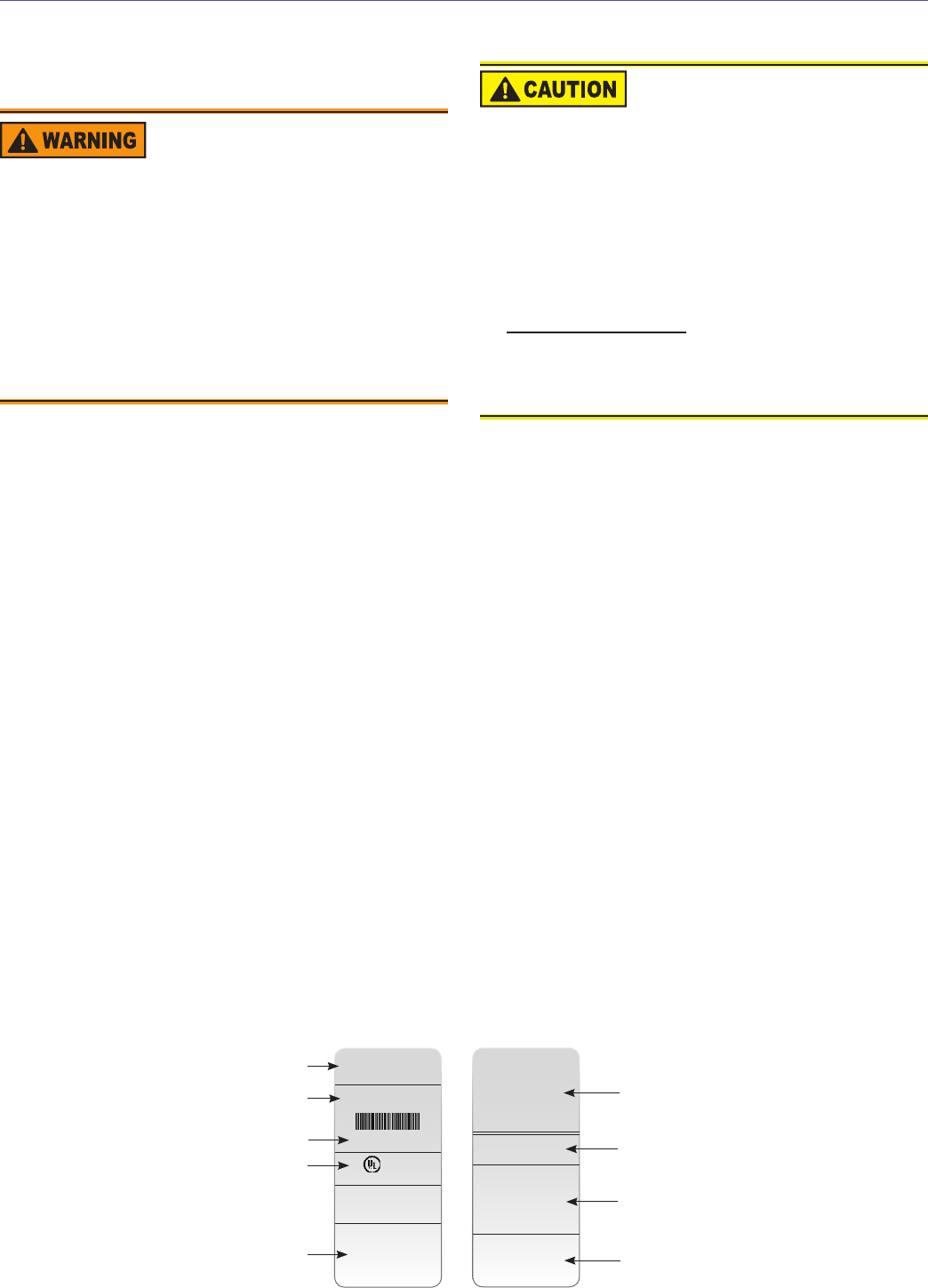

Figure 1 – Typical Nameplate

The burner requires combustion air and ventilation air

for reliable operation. Assure that the building and/or

combustion air openings comply with National Fire

Protection Standard for Oil-Burning Equipment, NFPA 31.

For appliance/burner units in confi ned spaces, the room

must have an air opening near the top of the room plus

one near the fl oor, each with a free area at least one

square inch per 1,000 Btu/hr input of all fuel burning

equipment in the room.

For other conditions, refer to the latest edition of NFPA 31

(CSA B1139-M91 in Canada).

If there is a risk of the space being under negative

pressure or of exhaust fans or other devices depleting

available air for combustion and ventilation, the appliance/

burner should be installed in an isolated room provided

with outside combustion air.

Clearances

With the burner installed in the appliance, there must be

adequate space in front of and on the sides of the burner

to allow access and operation. Verify that the clearance

dimensions comply with all local codes and with the

appliance manufacturer’s recommendations.

The fuel supply piping and tank must provide #1 or #2

fuel oil at pressure or vacuum conditions suitable for

the fuel unit (oil pump) on the burner. Refer to fuel unit

literature in the literature envelope in the burner carton to

verify allowable suction pressure.

If fuel supply is level with or higher than fuel unit —

When the fuel unit is not required to lift the oil, the

installation is usually suitable for either a one-pipe or

two-pipe oil system. The oil pressure at the inlet of

the fuel unit must not exceed 3 psig.

The fuel unit is shipped with the by-pass plug

installed. Leave the by-pass plug installed for all

low/high fi ring burners, regardless whether one-

pipe (with by-pass loop) or two-pipe. See Figure

9 for installation of the by-pass loop required for

one-pipe fuel supply installations. See Figure 10 for

connections to the fuel unit for two-pipe fuel supply

installations.

When fuel supply is below the burner fuel unit —

Use a two-pipe oil system when the fuel unit must lift

the oil more than 8 feet. The return line provided by the

two-pipe system is needed to minimize the effects of air-

related problems during operation.

○

○

Adequate Combustion and

Ventilation Air Supply Required

Failure to provide adequate air supply could

seriously affect the burner performance and result in

damage to the equipment, asphyxiation, explosion or

fi re hazards.

The burner cannot properly burn the fuel if it is not

supplied with a reliable combustion air source.

Follow the guidelines in the latest editions of the

NFPA 31 and CSA-B139 regarding providing

adequate air for combustion and ventilation.

y

y

Oil Supply Pressure

Control Required

Damage to the fi lter or pump seals could cause oil

leakage and a fi re hazard.

The oil supply inlet pressure to the burner cannot

exceed 3 psig.

Insure that a pressure limiting device is installed in

accordance with the latest edition of NFPA 31.

Do not install valves in return line.

Gravity Feed Systems: Always install an anti-siphon

valve in the oil supply line or a solenoid valve (RWB

Part # 21789) in the pump/nozzle discharge tubing

to provide backup oil fl ow cut-off protection.

y

y

y

y

Section: Pre-installation Checklist

LISTED

(FUEL) BURNER NO.P100000

SERIAL NUMBER

050214-00000

Control Circ: 120V/60Hz 4.5A

Motor Circ: 120V/60Hz 4.0A

Model “XX”

Series (Fuel) Burner

R.W. Beckett Corp.

Elyria, Ohio

Made in the U.S.A.

For use with Group 8 . . .

MP 1192 XX000 R00

X

X

X

X

X

X

XX000 R00

050214-00000

MFR’S SETTINGS

R.W. Beckett Construction &

Setting Data

R.W. Beckett Specifi cation

Number and Revision

Boiler Manufacturer and

Model, When Applicable

Additional Codes

General Model Information

Serial Number, Including Date Code

Rating Information

Approval Agency Symbols

Primary Group and Fuel