6104 BCF35 R11 Page 9

Set Dimension Z

Replace the rear access door on the burner, making

sure that the adjusting plate assembly is now

securely in the groove.

Loosen acorn nut (item d) in Figure 6. Slide the

nozzle line and plate assembly until dimension Z in

Figure 6 is:

CF2500A/CF2500 = 1-3/4 ±1/16”

CF3500A (tube KM) = 2-5/8” ±1/16”

CF3500A (tube KR)= 3-9/16” ±1/16”

When dimension Z (from end of air tube to fl at area

of front face of head) is correctly set, tighten acorn

nut (item d). Verify that the adjusting plate assembly

is properly seated in the groove.

Attach the oil line from the oil valve to the nozzle line

end. Tighten securely.

Before proceeding, check dimension Z once again.

Loosen acorn nut (item d) if necessary to reposition

the nozzle line. Once dimension Z is set, do not

loosen acorn nut (item d) again.

○

○

○

○

○

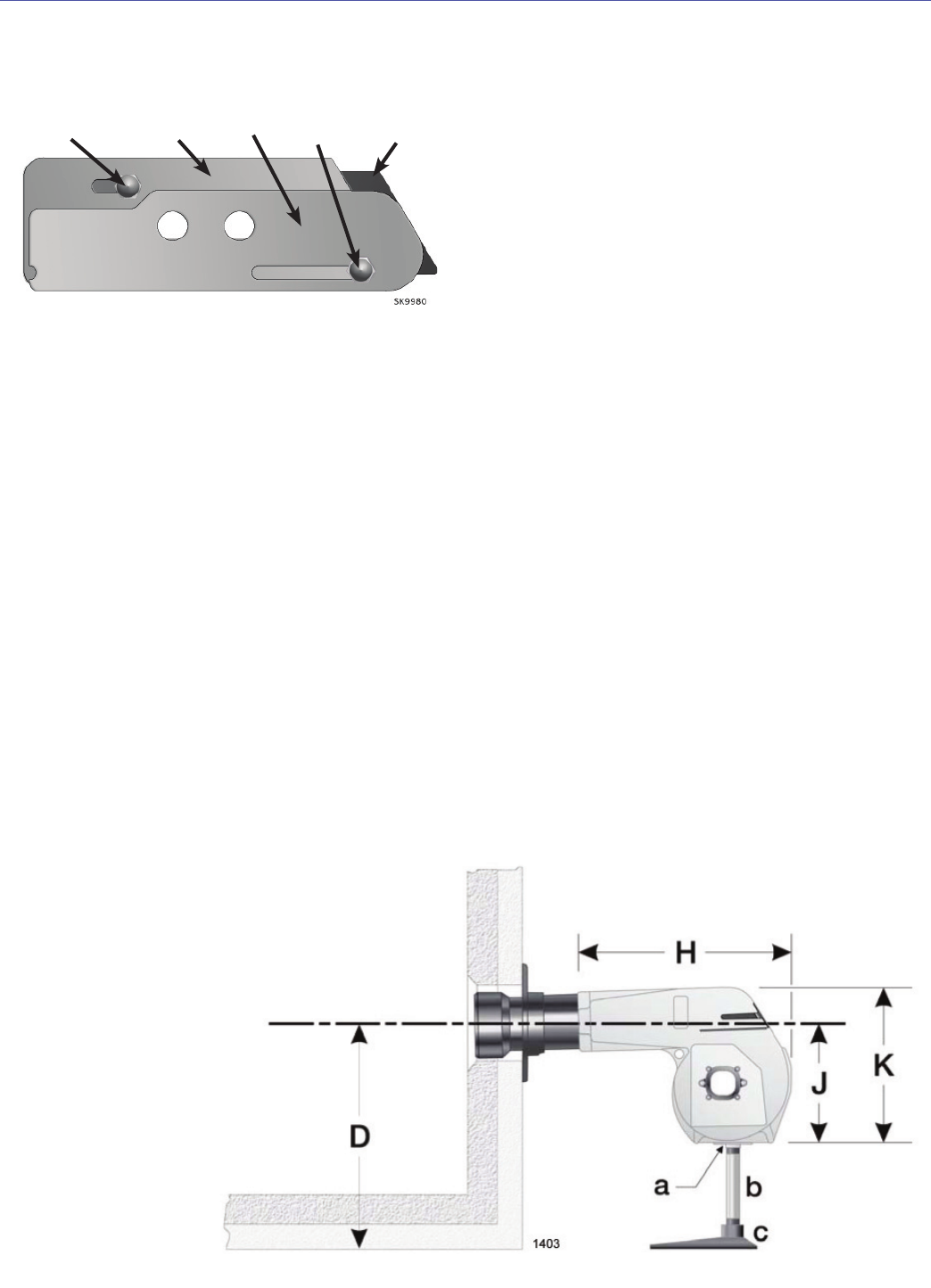

Figure 7 – Adjusting Plate Assembly

Legend (Figures 6 & 7)

a

Adjusting plate assembly

b

Spline nut for securing nozzle line

c

Bottom acorn nut

d

Top acorn nut (for setting dim. Z only)

e

Indicator adjusting plate

f

Secondary adjusting plate

g

Primary adjusting plate

Figure 8 – Burner Installed in Appliance Front

Legend

Description Inches

H

Housing total length 20”

J

Center to bottom of housing 14-1/2”

K

Overall housing height 22-3/4”

e

f

c

g

d

Insert Burner

Position the burner in the front of the appliance and

loosely tighten the nuts on the mounting studs. The

burner should be pitched downward 2° as shown in

Figures 3 and 4.

See Figure 8. Install the pedestal support kit

(recommended) by attaching the 3/4” NPT fl ange

(item a) to the bottom of the burner using the (4) #10

screws provided. Cut and thread (one end only) a

3/4” pipe nipple (item b) with length 11 inches less

than dimension D in Figure 8. Thread the pipe into

the fl ange.

Secure the burner to the appliance by tightening the

nuts on the burner fl ange mounting studs.

○

○

○

Section: Mount the Burner