6104 BCF35 R11 Page 15

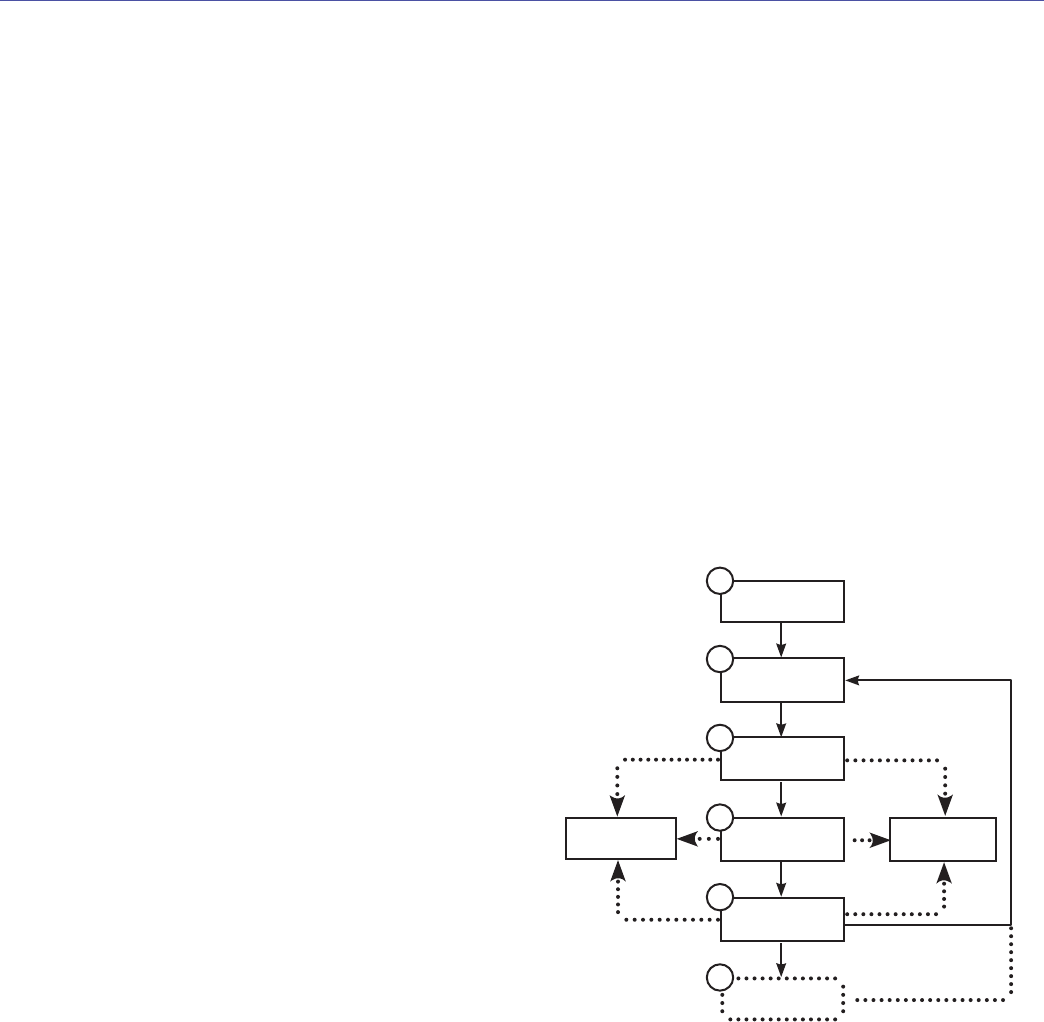

Typical Burner Sequence of Operation -

RM7897A Control

When fi ring over 20 GPH the CF2500 and CF3500A will

be supplied with a fl ame safeguard control. An airfl ow

switch and low-fi re start relay will also be supplied.

Consult local, state, and federal codes for burner

requirements above 20GPH.

Install the burner and all wiring in accordance with the

National Electrical Code and all applicable local codes or

requirements.

Wire the burner in compliance with all instructions

provided by the appliance manufacturer. Verify operation

of all controls in accordance with the appliance

manufacturer’s guidelines.

Initiate - Power is supplied to the control. The

control performs a self-check to ensure proper

operation.

Standby - the burner is idle waiting for a call for

heat. When the call for heat is initiated, the burner

will proceed to step 3.

Pre-purge - the burner will begin a 60 second pre-

purge to clear the combustion chamber. The burner

checks the air fl ow interlock to see if air is being

provided. If the air fl ow is not present the burner

will lockout if jumper JR3 is cut or recycle if the

jumper is intact.

Trial for Ignition - The RM7897A has two trial

periods. The fi rst is for light off the second is for

main fl ame establishing. The burner must see

fl ame within 10 seconds if jumper 1 is intact or 4

seconds if jumper 1 is clipped. If the fl ame is not

established, the burner will lockout if jumper 2 is

clipped or recycle if the jumper is intact. The burner

will then proceed to main fl ame establishing. If

fl ame is not sensed within 3 seconds the burner

will lockout or recycle depending on the status of

jumper 2.

Run: With a fl ame established and the control

continuing to detect a fl ame, the burner will operate

in the RUN mode until the load demand is satisfi ed

or a limit opens.

If terminals RC1 and RC2 are jumpered, the

burner operates in the Low-High-Off Mode.

The burner starts at Low, goes to High after the

fl ame stabilization period. Flame is extinguished

when the load is satisfi ed or a limit opens, and

the burner is sent to post purge.

1.

2.

3.

4.

5.

a.

If a high/low control has been wired between

terminals RC1 and RC2 the burner starts at

Low and is released to go High after the fl ame

stabilization period. It can repeatedly cycle

between low and high as necessary to meet

load demand until the load is satisfi ed or a limit

opens. The burner is then sent to post purge.

Post purge - The control enters a post purge cycle

to clear the combustion chamber of gases. Length

of the post purge is factory programmed at 15

seconds.

Cad Cell Resistance Indicator: During the burner

run state, click the reset button (less than 1 second)

to check the cad cell resistance range. The yellow

light will fl ash 1 to 4 times, depending on the

amount of light detected by the cad cell.

b.

6.

Section: Wire the Burner

Initiate

Stand by

Prepurge

Trial for

Ignition

Post Purge

Run

1

Recycle

Lockout

2

3

4

5

6

Figure 14 - Typical Burner Sequence of

Operation - RM7897A