6104 BCF35 R11 Page 7

Table 2 - Air Tube Capacity Versus Firebox Pressure

Maximum Firing Rate GPH

Model Tube

Firebox

Pressure

(In W.C.)

No

Reserve

Air

10% Turndown

(GPH)

CF2500 &

CF2500A

KP

0.0 25.0 22.5

0.2 24.8 22.3

0.4 24.6 22.3

0.6 24.5 22.1

0.8 24.3 21.9

1.0 24.1 21.7

CF3500A

KM/

KR

0.0 35.0 31.5

0.2 33.5 30.2

0.4 32.0 28.8

0.6 30.2 27.2

0.8 28.8 25.9

1.0 27.1 24.4

Note: 10% turndown indicates suffi cient reserve air to reduce

the CO

2

in the fl ue to 90% of its value.

Note: The above ratings may vary 5% due to variations in

actual job conditions.

Dust and Moisture

Mount the Burner

Mount Flange(s) on Air Tube

This section does not apply to burners with welded

fl anges.

Do not install air tube on burner.

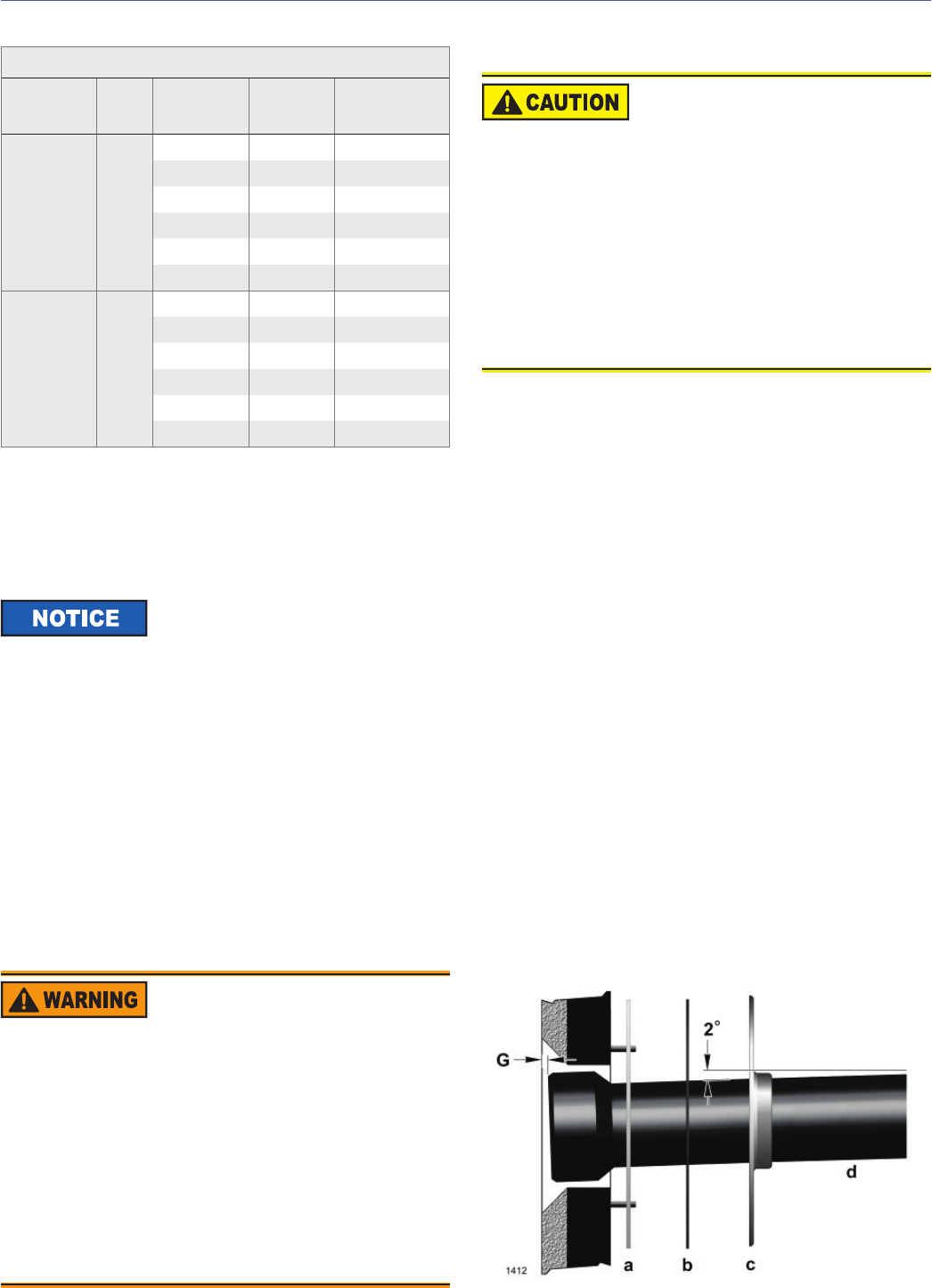

For non-pressure fi ring fl ange, refer to Figure 4:

Install gasket (item a) and fl ange (item c). Ignore the

next paragraph.

For pressure-fi ring fl ange, refer to Figure 4: Slide

gasket (item a) onto the air tube, making sure the

top of the air tube is up. Predrill holes in the pressure

fi ring plate (item b) to match the appliance studs.

Slide the pressure fi ring plate (item b) and fl ange

(item c) onto the air tube as shown. Wrap ceramic

fi ber rope (not shown) around the air tube and press

tightly into the inside diameter of the fl ange (item c).

Slide the air tube (item d) into position in the

appliance front. Tighten the fl ange-mounting-stud

nuts. Set the insertion of the air tube so dimension G

is 1/4” nominal.

Pitch the air tube at 2° from horizontal as shown and

secure the fl ange to the air tube.

○

○

○

○

○

Figure 4 – Mount Flange(s) on Air Tube

Stray Light

Protect Against Stray

Light Lockout. Failure

to follow these instructions could cause

loss of burner operation resulting in no

heat, an unplanned process interruption,

work stoppage and the potential for frozen

plumbing or other cold weather property

damage.

The control must detect a dark, no-fl ame condition

in order to start the burner or it will hold in the stray

light lockout mode.

Shield the burner view window from direct exposure

to intense light.

○

○

Protect Against Dust and

Moisture

Wet, dusty environments could lead to blocked air

passages, corrosion damage to components, impaired

combustion performance and result in asphyxiation,

explosion or fi re.

This burner is designed for clean, dry installations.

Electrical controls are not protected against rain or sprayed

water.

Keep the installation clear of dust, dirt, corrosive vapors,

and moisture.

Protective covers and more frequent maintenance may be

required.

y

y

y

y

Section: Mount the Burner

Protect the Air Tube From

Overheating

Overheating could cause damage to the air tube and

other combustion components leading to equipment

malfunction and impaired combustion performance.

The end of the air tube must not extend into the

combustion chamber unprotected unless it has

been factory-tested and specifi ed by the appliance

manufacturer.

Position the end of the air tube 1/4” back from

fl ush with the refractory inside entry wall to prevent

damage from overheating.

y

y