10

Form 6104 BCF10-R06

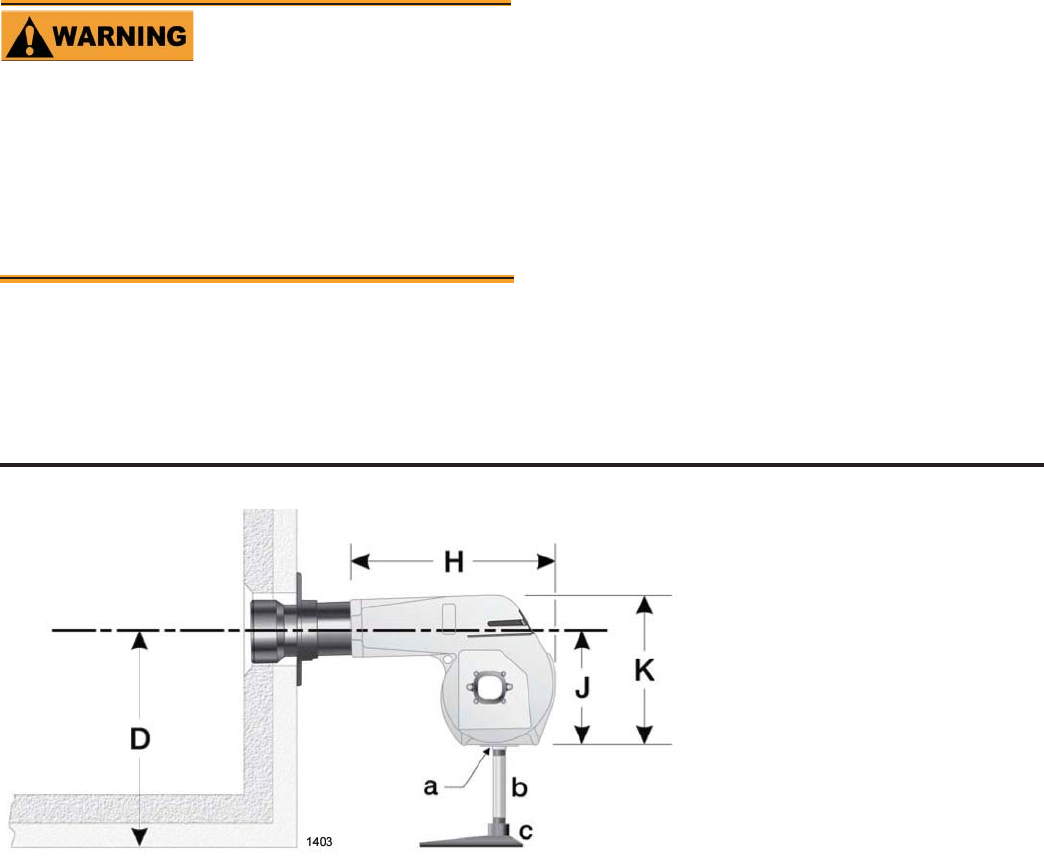

Figure 7 - Burner installed in appliance front

Legend

H Housing total length — 18”

J Center to bottom of housing — 10-7/8”

K Overall housing height — 13-3/8”

Fuel unit by-pass plug

The burner is shipped without the by-pass plug in-

stalled.

Intall the by-pass plug in two-pipe oil supply systems

ONLY.

y

y

Failure to comply could cause immediate pump

seal failure, pressurized oil leakage and the po-

tential for a fi re and injury hazard.

Do Not Install By-pass

Plug with 1-Pipe System

Use a two-pipe system, one-pipe system with by-pass

loop, or remove the by-pass plug when using with a

one-pipe system and no by-pass loop

y

Insert burner

Position the burner in the front of the appliance and loosely

tighten the nuts on the mounting studs. The burner should

be pitched downward 2° as shown in Figures 2 and 3.

See Figure 7. Install the pedestal support kit (recommend-

ed) by attaching the ¾” NPT fl ange (item a) to the bottom

of the burner using the (4) #10 screws provided. Cut and

thread (one end only) a ¾” pipe nipple (item b) with length

10 inches less than dimension D in Figure 7. Thread the

pipe into the fl ange. Then slip the pipe end into the fl oor

fl ange (item c).

Secure the burner to the appliance by tightening the nuts on

the burner fl ange mounting studs. Then secure the pedestal

support fl oor fl ange set screw to the pipe.

y

y

y

Oil supply/return lines

Install the oil tank and oil lines in accordance with all

applicable state and local codes.

Size the oil supply and return lines using the guidelines

given in the fuel unit literature included in the literature

envelope. Oil line fl ow rate will equal the burner rate for

one-pipe systems. For two-pipe systems, refer to Table 3

for the fuel unit gear set capacity - the rate at which fuel

is recirculated when connected to a two-pipe system. Size

two-pipe oil lines based on this fl ow rate.

Use continuous lengths of heavy-wall copper tubing, routed

under the fl oor where possible. Do not attach fuel lines to

the appliance or to fl oor joists if possible. This will reduce

vibration and noise transmission problems.

Install an oil fi lter sized to handle the fuel unit gearset fl ow

capacity (Table 3) for two-pipe systems. Size the fi lter

for the fi ring rate for one-pipe systems. Locate the fi lter

immediately adjacent to the burner fuel unit.

Install two high-quality shut-off valves in accessible

locations on the oil supply line. Locate one valve close

to the tank. Locate the other valve close to the burner,

upstream of the fuel fi lter.

y

y

y

y

y

Connect Fuel Lines