10

Section: Drive Component Maintenance

B. Pump Maintenance

General Pump Information

Important information - Long or oversized inlet lines may

require the pump to operate dry during initial bleeding

period. In such cases, the priming may be assisted

by injecting fuel oil in the pump gear set. Under lift

conditions, lines and fi ttings must be air tight. To assure

this, “Pipe Dope” may be applied to both the used and

unused inlet and return fi ttings. Do NOT use Tefl on tape

or compression fi ttings

Mounting Position - Beckett CleanCut pump may be

mounted in any position (except upside-down in a single

pipe installation).

Vacuum Check - A Vacuum Gauge may be installed in

either of the 1/4” NPT inlet ports.

Pressure Check- When a pressure check is made, use

the nozzle port. If the bleed port is used, the reading on

the gauge should be approximately 5 psig higher than the

pressure reading on the nozzle port. See Figure 8.

Cutoff Check - To check cutoff pressure dead head a

pressure gauge in the nozzle port. Run the burner for a

short period of time. Shut the burner off. The pressure

will drop and hold above zero. Pressurized or gravity feed

installations must not exceed 3 psig on inlet line or return

line at the pump per NFPA 31. A pressure greater than 10

psig may cause damage to the shaft seal.

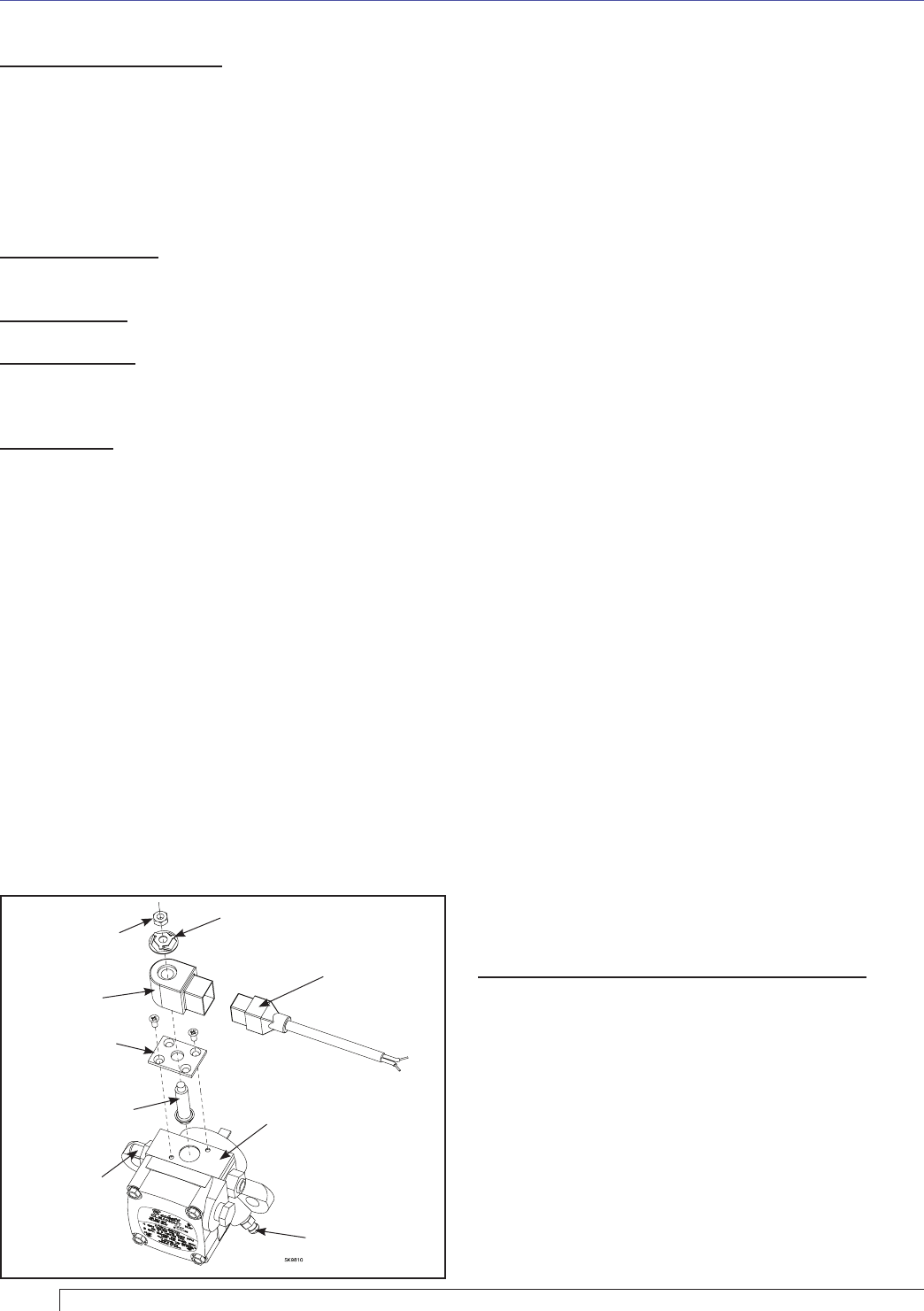

C. Valve Coil and Stem Replacement

To determine if the valve coil requires replacement perform

the following steps.

1. Remove the cord set from the valve.

2. Place the leads from an ohmmeter across the coil.

3. A 12Vdc volt coil should measure between 15 and

25 ohms.

4. If the meter indicates an open circuit, replace the coil.

To check pump operation perform the following.

1. Check the operating pressure by removing the copper

tubing from the nozzle line and installing a pressure

gauge in the line. With the motor running and the coil

energized, check the gauge. The pressure should read

100 psig unless otherwise stated.

2. To check the cutoff function, deadhead the pressure

gauge onto the copper connector tube attached to the

nozzle port. Run the burner for a short period of time.

Shut the burner off; the pressure should drop and hold.

To replace the coil and/or pump assembly perform the

following steps.

1. Before servicing, turn off and/or disconnect all power

to the burner.

2. Remove the copper tube assembly when replacing

the pump or when removing the coil and the tube

blocks the coil.

3. Using a fl at tip screwdriver, press the fl at tip into the

spring washer to prevent it from rotating.

4. Using a 10mm wrench or adjustable wrench, remove

the nut and spring washer.

5. Remove the coil by lifting it straight up.

6. Remove the two base plate screws, then the base

plate by lifting straight up.

7. Remove valve stem assembly by pulling straight up.

8. To install the new stem and coil assemblies, follow

the above steps in reverse order, tightening each

part as you go.

9. Restore power, start the burner and perform

the combustion test described previously in this

manual.

Start Up Burner & Set

Combustion

A. Basic Burner Operation

Typical Constant Duty Ignition Confi guration - With

this Beckett ADC oil burner confi guration, the motor

and igniter operate continuously while the valve that

controls oil fl ow is cycled by the switches on the power

washer. The motor is used to drive the blower and pump.

The rotational speed of the motor is determined by the

voltage supplied and the load placed on the motor. Pump

pressure and air settings are the main factors affecting

the motor load. The igniter converts battery DC voltage

into a high voltage spark to ignite the oil. The igniter is

capable of running continuously as long as the blower

wheel is circulating air across the igniter base. The pump

and solenoid valve are used to control the fl ow of oil from

the reservoir to the nozzle.

SK9810

10mm Nut

Coil

Base Plate

Stem Assembly

Nozzle Port

Fitting

Cordset

Pump Assembly

Bleed Valve

Spring Washer

Figure 8. – Pump and Valve Assemblies