10 Installation

Travis Industries 4050225 100-01154

Pellet Vent Type

• Must be 4" diameter Type "L"(except for masonry fireplace installations) - or - connect the

vent to a factory built type "A" chimney. All vent joints (including adapters, elbows, etc…)

must be sealed with 500° F. RTV silicone.

Installing the Pellet Vent

Seal each vent section (including

adapters, elbows, etc...) by

injecting a liberal amount of 500°

F. RTV silicone into the gap

between sections.

500° F. RTV

Silicone

• Horizontal sections must have a 1/4" rise every 12" of travel.

• Pellet vent connections must be sealed airtight with 500° F. RTV silicone and screwed

together with at least three sheet metal screws.

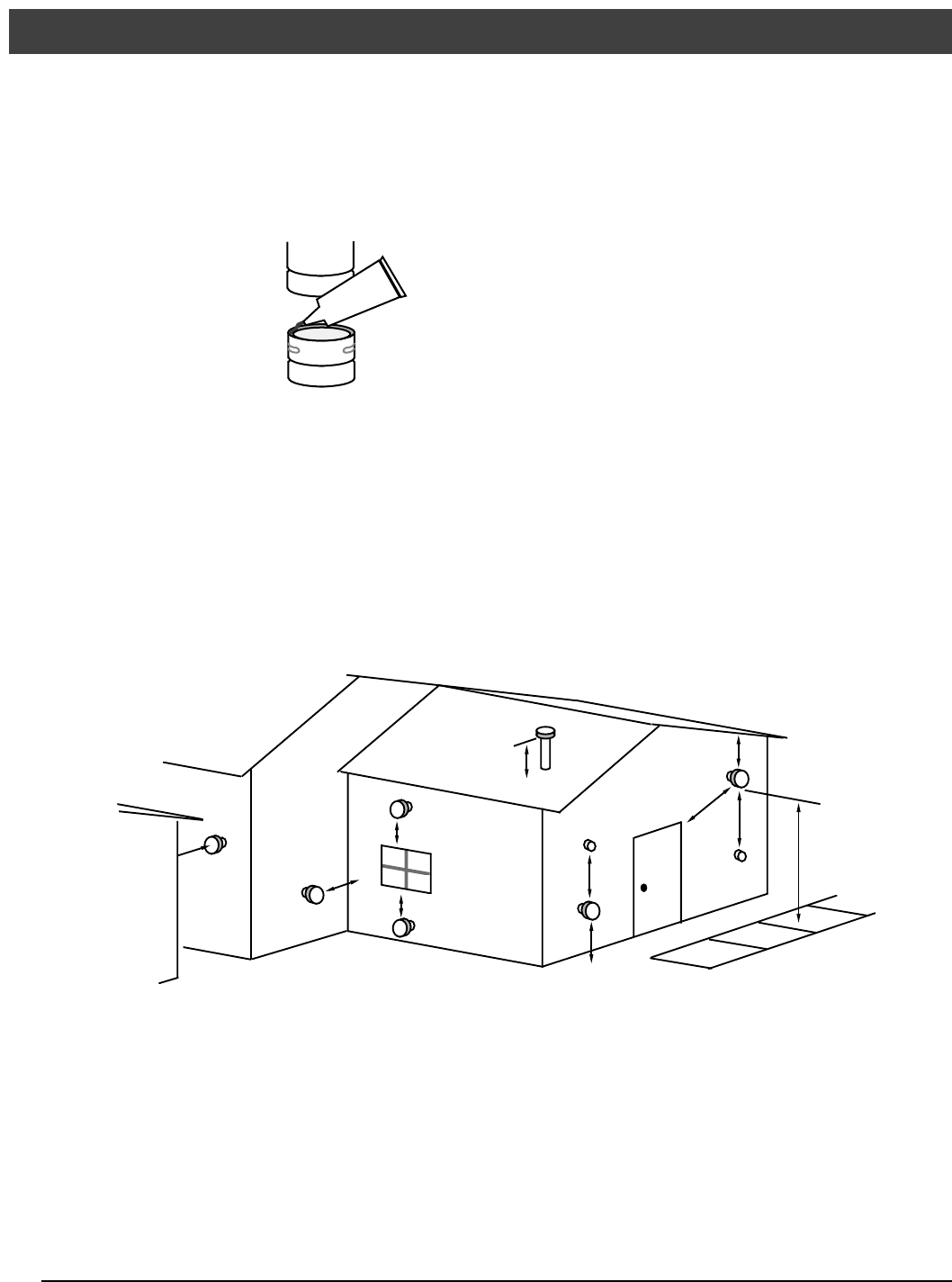

Pellet Vent Termination (See the illustration below)

• Must have an approved cap (to prevent water from entering) or a 45° downturn.

• If the termination is located on a windy side of the house, an approved house shield is

recommended to prevent soot from building up on the side of the house.

• Must not be located where it will become plugged by snow or other material.

• Horizontal terminations must protrude 12" from the wall, verticall terminations require 24".

H

G

A

D

F

NOTE: Measure clearances to the nearest edge of the exhaust hood.

A

E

B

C

F

X

A Minimum 4' clearance below or beside any door or window that opens

Minimum 1’ clearance below or beside any window that does not open.

B Minimum 1' clearance above any door or window that opens

C Minimum 2' clearance from any adjacent building

D Minimum 7' clearance above any grade when adjacent to public walkways

NOTE: Vent may not terminate in covered walkway or breezeway.

E Minimum 2' clearance above any grass, plants, or other combustible materials

F Minimum 3' clearance from any forced air intake of any other appliance

G Minimum 2' clearance below eaves or overhangs

H Minimum 1' clearance horizontally from combustible wall

X Must be a minimum of 2' above the roof